Plastic Injection Molding Services

Yigu Technology expertise encompasses a wide array of materials, enabling us to create tools that meet diverse requirements. We excel in batch injection molding, capable of producing anywhere from 50 オーバー 100,000 finished parts in an extensive range of plastics. Whether you need a small batch for initial testing or a large-scale production run, Yigu is committed to delivering high-quality, tailored solutions that align with your specific needs.

Our Injection Molding Capability

Yiguテクノロジー is a renowned plastic parts manufacturer 中国で, widely recognized as a leading 射出成形 provider. Our state-of-the-art facility is designed to offer a comprehensive suite of services, ensuring that we meet the highest standards of quality and efficiency. Our capabilities encompass Low Volume Injection Molding, which is perfect for initial production runs and market testing, as well as full-scale 射出成形 for high-volume orders. We also specialize in 成形を挿入します そして Two-color Injection Molding, providing advanced solutions that cater to the diverse needs of various industries. Whether you need precision components for automotive applications or durable parts for consumer electronics, Yigu Technology is dedicated to delivering high-quality, customized solutions that meet your specific requirements.

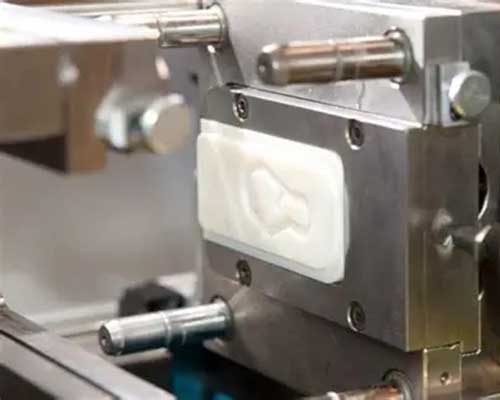

迅速なツール

Rapid tooling involves creating precise cavities for shaping materials, typically using metal or silicone. Processes include CNC machining, EDM, and 3D printing for high accuracy.

Standard injection molding

Conventional single-color and single-material molding is the most widely used.

Insert molding molding

Insert Molding involves molding plastic around an insert or pre-formed component, such as a metal or plastic part, to create a finished product.

Two-color injection molding

Injecting two different types of plastic into the same mold to produce a single part with two different colors or materials.

Plastic Injection Molding Parts Display

The products displayed below have been approved by the customer, and we strictly abide by the confidentiality agreement.

Injection Molding Material Options

Injection molding uses a huge range of plastics, making it ideal for many applications across nearly every industry.

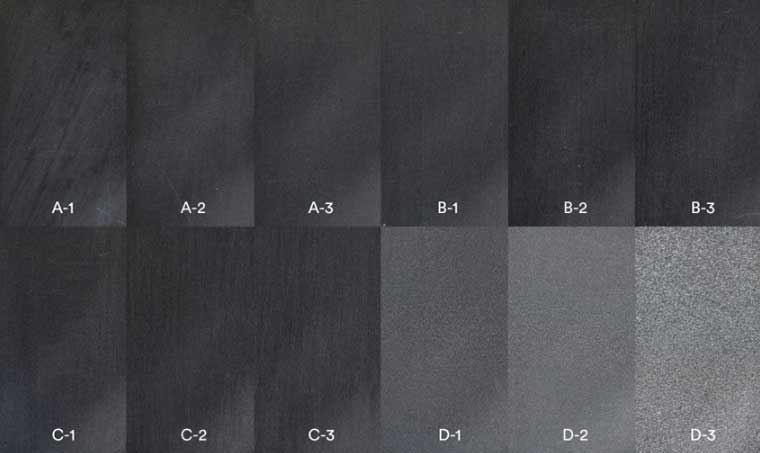

Our Injection Molding Finishes Options

Yigu Technology provide various finishes, which can be specified in the quote request form, such as painting and heat tapping inserts. Below are some examples of the secondary operations that we offer:

- Pad printing

- 絵画

- シルクスクリーニング

- Ultrasonic welding

- レーザー彫刻

- UV coating

- Heat staking

- Hot stamping

- Post-mold machining

- Inserts

Complete your Injection Molding Parts in 5 ステップ

Why Choose Our Injection molding サービス

Yiguテクノロジー, a premier injection molding company in China, specializes in delivering comprehensive manufacturing solutions tailored to meet diverse production demands, から 低音量 に 量産. Our commitment to excellence is underscored by our ISO 9001:2015 certification and our team of over 190 high-end technical personnel. We are equipped with more than 35 horizontal and vertical injection molding machines, ensuring we have the capacity and capability to handle projects of any scale.

Our state-of-the-art injection molding facility offers optimal molding solutions, with machine capacities ranging from 15-ton to 3000-ton. This wide range makes us well-suited for both 小型バッチプロダクション そして 量産, catering to the unique requirements of the product development process. Utilizing cutting-edge techniques, we can manufacture molds in as quickly as 2 週, guaranteeing both efficiency and quality.

Leveraging our robust production capabilities in プラスチック射出成形, we can flexibly manage production cycles to fulfill all your precision product needs. Whether you require components for the automotive industry または 医療機器, Yigu Technology is your reliable partner, ensuring that every product meets the highest standards of precision and reliability.

Advantages of Injection Molding

精度 & 複雑: Our injection molding process excels in producing parts with 高精度 そして 複雑なジオメトリ. Whether your design involves intricate details or tight tolerances, our advanced technology ensures that every component is manufactured to exact specifications, maintaining consistency across all units.

物質的な汎用性: We offer a wide range of 材料オプション to suit your specific requirements. From high-performance engineering plastics to eco-friendly materials, our expertise allows us to select and utilize the best materials for your project, ensuring optimal performance and durability.

費用対効果: Injection molding is highly 費用対効果, 特に大量生産用. The process can be fully automated, significantly reducing the need for manual labor. This not only increases efficiency but also ensures consistency and reliability, leading to lower overall production costs.

Surface Finish Options: Our injection molding capabilities extend to a variety of surface finish options. We can incorporate textures, patterns, and other surface treatments directly into the mold, eliminating the need for secondary processes. This not only enhances the aesthetic appeal but also reduces production time and costs.

Injection Molding Applications

医療アプリケーション: Injection molding plays a crucial role in the medical industry, where precision and reliability are paramount. We produce a wide range of medical devices and equipment, including syringes, 吸入器, and implantable devices. Our processes ensure that these critical components meet the highest standards of quality and safety, making them suitable for use in various medical procedures and treatments.

Industrial Components: In the industrial sector, injection molding is essential for manufacturing durable and functional components. We specialize in producing items such as upholstery, 楽器パネル, そして 構造コンポーネント. These parts are designed to withstand rigorous use, ensuring long-term performance and reliability in demanding industrial environments.

自動車産業: For the automotive sector, injection molding is a key technology for producing various vehicle components. We manufacture parts like ダッシュボード, ドアパネル, そして バンパー, which are integral to both the functionality and aesthetics of modern vehicles. Our expertise ensures that these components meet the stringent requirements of the automotive industry, providing both durability and design flexibility.