If you work in industries like chemical processing, 医療機器, または海洋工学, you need bearing steel that can resist harsh chemicals, 水分, and wear—all at once.GB 9Cr18Mo stainless bearing steel—a Chinese national standard martensitic stainless steel—delivers exactly this. It combines strong corrosion resistance with the hardness needed for bearings, solving the common problem of rusted or worn-out parts in tough environments. このガイドは、その重要なプロパティを分解します, 実世界のアプリケーション, 製造プロセス, そして、それが他の素材とどのように比較されますか, helping you make the right choice for your project.

1. Material Properties of GB 9Cr18Mo Stainless Bearing Steel

GB 9Cr18Mo’s unique composition—high chromium and molybdenum—sets it apart from standard bearing steels. そのプロパティを詳細に調べてみましょう.

1.1 化学組成

GB 9Cr18Mo follows strict Chinese National Standards (GB/T 1220), ensuring consistent performance for corrosion and wear resistance. 以下はその典型的な化学メイクです:

| 要素 | シンボル | コンテンツ範囲 (%) | 重要な役割 |

|---|---|---|---|

| 炭素 (c) | c | 0.90 - 1.00 | 硬度を高め、耐摩耗性を高めます |

| クロム (cr) | cr | 17.00 - 19.00 | 保護酸化物層を形成します (腐食抵抗に重要です) |

| モリブデン (MO) | MO | 0.90 - 1.30 | Boosts corrosion resistance to chemicals (例えば。, 酸) and improves high-temperature strength |

| マンガン (Mn) | Mn | ≤ 0.80 | 製造中の作業性が向上します |

| シリコン (そして) | そして | ≤ 0.80 | Aids deoxidation during steelmaking |

| 硫黄 (s) | s | ≤ 0.030 | Minimized to avoid brittleness and fatigue cracks |

| リン (p) | p | ≤ 0.035 | Controlled to prevent grain boundary cracking |

| ニッケル (で) | で | ≤ 0.60 | Trace amount; minor boost to ductility |

| バナジウム (v) | v | ≤ 0.10 | Trace element; refines grain structure for better strength |

1.2 物理的特性

These properties describe how GB 9Cr18Mo behaves under physical conditions like temperature and magnetism:

- 密度: 7.75 g/cm³ (slightly lower than standard carbon bearing steels like GCr15)

- 融点: 1,450 - 1,480 °C (2,642 - 2,696 °F)

- 熱伝導率: 24.5 w/(M・k) で 20 °C (室温)—lower than carbon steels, typical of stainless grades

- 熱膨張係数: 10.6 ×10⁻⁶/°C (から 20 - 100 °C)

- 磁気特性: 強磁性 (磁石を引き付けます)—unlike non-magnetic austenitic stainless steels (例えば。, アイシ 304), making it easy to sort and inspect.

1.3 機械的特性

GB 9Cr18Mo’s mechanical performance is achieved through heat treatment (クエンチングと焼き戻し). 以下は典型的な値です:

| 財産 | Measurement Method | 典型的な値 |

|---|---|---|

| 硬度 (ロックウェル) | HRC | 58 - 62 HRC |

| 硬度 (ビッカーズ) | HV | 550 - 600 HV |

| 抗張力 | MPA | ≥ 1,600 MPA |

| 降伏強度 | MPA | ≥ 1,400 MPA |

| 伸長 | % (で 50 mm) | ≥ 5% |

| 衝撃の靭性 | j (で 20 °C) | ≥ 10 j |

| Fatigue Limit | MPA (rotating beam) | ≥ 700 MPA |

1.4 その他のプロパティ

GB 9Cr18Mo’s standout properties make it ideal for harsh environments:

- 耐食性: Excellent—resists saltwater, 軽度の酸, および化学物質. Outperforms standard carbon bearing steels (例えば。, GCr15) and even matches some high-end stainless grades like AISI 440C.

- 耐摩耗性: High carbon and chromium form hard carbides, ensuring it can handle rolling/sliding contact in bearings.

- ハーデン剤: Good—can be heat-treated to uniform hardness across thick sections, perfect for large bearings.

- 寸法安定性: Minimizes distortion during heat treatment, ensuring precision in critical parts like bearing races and rolling elements.

- Martensitic Structure: Yes—this structure (formed during quenching) gives it both hardness and magnetism, which is key for bearing performance.

2. Applications of GB 9Cr18Mo Stainless Bearing Steel

GB 9Cr18Mo’s corrosion + wear resistance makes it perfect for wet, 化学薬品, or sanitary environments. ここに最も一般的な用途があります:

- ベアリング: Corrosion-resistant bearings in chemical pumps, marine engines, and medical equipment—where water or chemicals would rust standard steel.

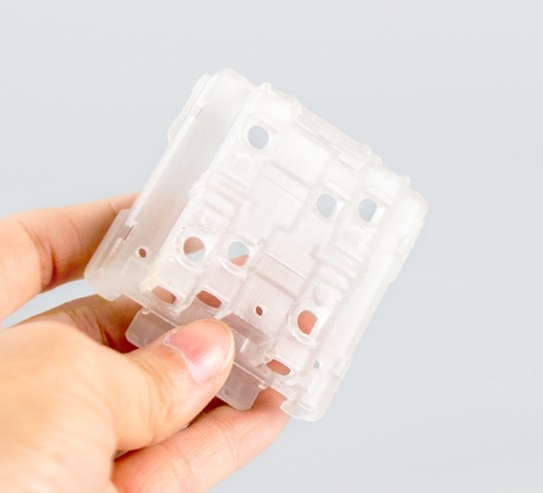

- Rolling Elements: Balls, ローラー, or needles in wet bearings (例えば。, washing machine bearings or boat propeller shafts).

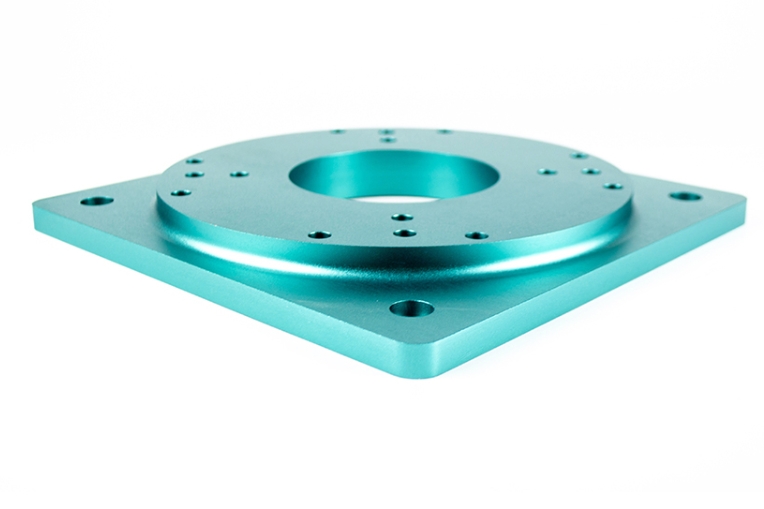

- Races: Inner/outer rings of bearings in food processing machines or pharmaceutical mixers—needing frequent cleaning and rust resistance.

- 自動車コンポーネント: Bearings in car washes, undercarriage parts (exposed to salt and rain), or fuel systems (resisting fuel chemicals).

- 産業機械: Bearings in chemical processing mixers, wastewater treatment equipment, and humid factory gearboxes.

- 航空宇宙コンポーネント: Small bearings in aircraft hydraulic systems (resisting hydraulic fluids and moisture).

- 医療機器: Bearings in surgical drills, sterilizable tools, and diagnostic equipment (able to withstand autoclaving).

- 食品加工装置: Bearings in conveyors, dough mixers, and filling machines—meeting food safety standards (例えば。, GB 4806 for China).

- 海洋アプリケーション: Bearings in boat engines, deck winches, and underwater pumps (fighting saltwater corrosion).

- 化学処理装置: Bearings in acid tanks, solvent transfer pumps, and chemical reactors.

3. Manufacturing Techniques for GB 9Cr18Mo

Producing GB 9Cr18Mo requires techniques that preserve both its corrosion and wear resistance. Here’s the typical process:

- スチール製造:

- GB 9Cr18Mo is made using an 電気弧炉 (EAF) with argon oxygen decarburization (aod). This process controls carbon content (for hardness) and ensures high chromium/molybdenum levels (腐食抵抗用), meeting GB/T 1220 基準.

- ローリング:

- 製鉄所の後, the metal is ホットロール (で 1,100 - 1,200 °C) into billets or bars. 精密部品用 (like small bearing rings), その コールドロール (室温) to improve surface finish and dimensional accuracy.

- Precision Forging:

- 複雑な部品 (例えば。, custom bearing races) are forged into near-final shapes at high temperatures. Forging refines the grain structure, enhancing both strength and corrosion resistance.

- 熱処理:

- The most critical step to unlock GB 9Cr18Mo’s performance:

- 消光: Heat the steel to 950 - 1,000 °C, then rapidly cool it in oil to harden (forms a martensitic structure).

- 焼き戻し: Reheat to 150 - 200 °C (twice for consistency) to reduce brittleness while maintaining hardness and corrosion resistance.

- The most critical step to unlock GB 9Cr18Mo’s performance:

- 機械加工:

- 加熱後の治療, parts are machined using 研削 (for ultra-smooth surfaces, reducing friction in bearings) そして 旋回 (for cylindrical shapes like bearing races). CNC machines ensure tight tolerances (±0.001 mm) for precision fits.

- 表面処理:

- パフォーマンスを向上させるためのオプションの手順:

- 危険性: Treat with nitric acid to strengthen the chromium oxide layer, boosting corrosion resistance.

- 研磨: Achieve a mirror finish for sanitary applications (例えば。, 食品加工), making cleaning easier and preventing bacterial buildup.

- コーティング: Thin PTFE coatings for extra resistance to strong chemicals (例えば。, in industrial acid tanks).

- パフォーマンスを向上させるためのオプションの手順:

- 品質管理:

- Rigorous testing ensures compliance with GB standards:

- 化学分析: Use spectrometry to verify chromium, モリブデン, および炭素含有量.

- Corrosion testing: Salt spray tests (per GB/T 10125) to check resistance to saltwater.

- Hardness testing: Measure Rockwell hardness to ensure HRC 58–62.

- Dimensional inspection: Use coordinate measuring machines (CMMS) to check part tolerances.

- Rigorous testing ensures compliance with GB standards:

4. ケーススタディ: GB 9Cr18Mo in Action

Real-world examples show how GB 9Cr18Mo solves industry challenges.

ケーススタディ 1: Chemical Processing Bearing Reliability

A Chinese chemical plant faced monthly bearing failures in their acid transfer pumps. The original bearings used GCr15 steel, which corroded quickly in the acidic environment. Switching to GB 9Cr18Mo bearings (with passivation) extended bearing life to 12 数ヶ月. This reduced maintenance downtime by 90% and saved $150,000 annually in replacement parts.

ケーススタディ 2: Marine Equipment Bearing Durability

A shipyard struggled with propeller shaft bearing failures (毎 6 数ヶ月) due to saltwater corrosion. They replaced standard stainless steel bearings with GB 9Cr18Mo bearings. Post-switch, the bearings lasted 3 年, 交換費用を削減します 75% and reducing ship downtime for repairs.

5. GB 9CR18MO対. その他の材料

How does GB 9Cr18Mo compare to other common bearing steels and materials? 下の表はそれを分解します:

| 材料 | Similarities to GB 9Cr18Mo | 重要な違い | に最適です |

|---|---|---|---|

| AISI 440C | Stainless bearing steel; マルテンサイト | Lower molybdenum (0.40–0.60% vs. 0.90–1.30%); 私たち. 標準 | Global supply chains; 軽度の化学物質 |

| JIS SUS440C | Stainless bearing steel; マルテンサイト | Lower molybdenum; 日本の標準 | Japanese machinery; 食品加工 |

| JIS SUJ2 | Bearing-grade; 耐摩耗性 | 耐食性はありません; rusts in water | Dry industrial bearings |

| GCr15 | Bearing-grade; 中国の基準 | 耐食性はありません; 炭素鋼 | Dry Chinese machinery (例えば。, モーター) |

| 100Cr6 | Bearing-grade; 耐摩耗性 | 耐食性はありません; 欧州標準 | Dry automotive/light industrial bearings |

| で 1.4125 | Stainless bearing steel; マルテンサイト | Lower molybdenum; 欧州標準 | European food/marine apps |

| セラミックベアリング (si₃n₄) | 耐性耐性; 耐摩耗性 | 非磁性; より高価です; 脆い | Ultra-high-speed wet apps (例えば。, racing engines) |

| Plastic Bearings (PTFE) | 耐性耐性 | Low strength; no heavy loads | Low-load wet apps (例えば。, household pumps) |

Yigu Technology’s Perspective on GB 9Cr18Mo

Yiguテクノロジーで, GB 9Cr18Mo is our top choice for clients in Chinese chemical, 海兵隊, および医療産業. Its high molybdenum content gives it better chemical resistance than AISI 440C or JIS SUS440C—critical for harsh acids or saltwater. We pair it with precision grinding and passivation to meet GB safety standards, making parts that last 5–8x longer than GCr15 in wet environments. For clients needing global compatibility, we also offer GB 9Cr18Mo as a direct alternative to AISI 440C, ensuring consistent performance across markets.

FAQ About GB 9Cr18Mo Stainless Bearing Steel

- Why is molybdenum important in GB 9Cr18Mo?

モリブデン (0.90–1.30%) boosts GB 9Cr18Mo’s resistance to chemicals (like acids) and high temperatures—making it better than stainless bearing steels with less molybdenum (例えば。, AISI 440C) for harsh industrial environments. - Can GB 9Cr18Mo be used in food processing?

Yes—when polished and passivated, it meets food safety standards (例えば。, 中国のGB 4806 and global FDA standards). Its corrosion resistance prevents rust from contaminating food, and its smooth surface is easy to clean. - Is GB 9Cr18Mo interchangeable with AISI 440C?

Mostly yes—both are martensitic stainless bearing steels with similar wear and corrosion resistance. GB 9Cr18Mo has more molybdenum (better for chemicals), but it can replace AISI 440C in most applications like marine bearings or medical tools.