製品開発中の場合, you’ve probably heard the term “CNC metal prototype processing.” But what exactly does it mean, and why is it so critical for bringing new products to market? 簡単に言えば, CNC metal prototype processing is a manufacturing method that uses Computer Numerical Control (CNC) technology to create metal prototypes—physical models of a product design. These prototypes let you test, validate, and refine your design before full-scale production, saving time, お金, and reducing risks. Let’s break down everything you need to know.

1. Key Materials Used in CNC Metal Prototype Processing

Not all metals work the same for prototypes. The material you choose depends on your product’s final use (例えば。, 強さ, 耐食性) and testing needs. Below is a table of the most common metals, their properties, そして理想的なアプリケーション:

| Metal Material | キープロパティ | 典型的なアプリケーション |

| アルミニウム合金 | 軽量 (2.7 g/cm³), good machinability, 低コスト | Aerospace parts, 家電 (例えば。, phone frames) |

| Copper | High electrical conductivity (59.6 × 10⁶ S/m), excellent thermal transfer | 電気コンポーネント (例えば。, コネクタ), heat sinks |

| Stainless Steel | Corrosion-resistant, 高強度 (tensile strength up to 500 MPA) | 医療機器, 自動車部品, kitchen appliances |

| Titanium Alloy | Ultra-strong (tensile strength 860–980 MPa), 生体適合性, 軽量 | Medical implants (例えば。, hip joints), aerospace engine parts |

| Zinc Alloy | Low melting point (385°C), easy to cast and machine | おもちゃの部品, decorative components (例えば。, hardware fittings) |

| マグネシウム合金 | Lightest structural metal (1.8 g/cm³), good shock absorption | Laptop casings, automotive lightweight parts |

2. Step-by-Step Process of CNC Metal Prototype Processing

Creating a CNC metal prototype isn’t a one-step job—it follows a structured workflow to ensure precision. Here’s a clear breakdown of the 5 core steps:

- Design & Programming: 初め, your team turns 2D product drawings into a 3D model using CAD (コンピューター支援設計) ソフトウェア (例えば。, SOLIDWORKS, AutoCAD). それから, CAM (コンピューター支援の製造) software converts this 3D model into a CNC program—code that the machine can read. This step is critical: even a small error in programming can ruin the prototype.

- 材料の選択: Choose a metal blank (the raw material) that matches your final product’s material. 例えば, if your end product is a stainless steel medical tool, use stainless steel for the prototype to test real-world performance.

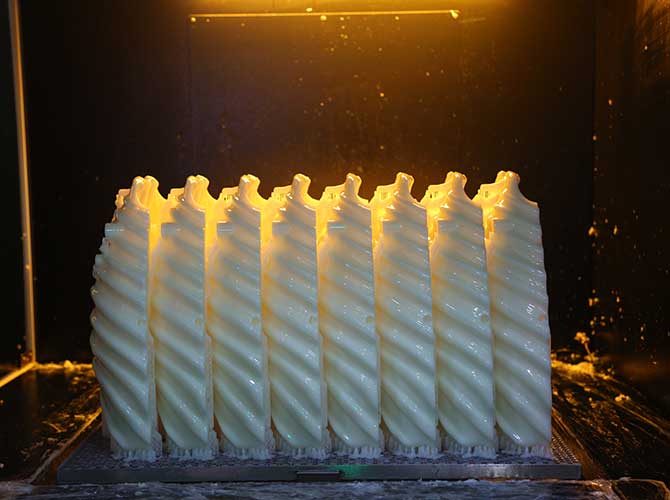

- CNC加工: Load the CNC program into the machine (例えば。, CNC mill, lathe). The machine uses cutting tools (ドリル, ミルズ) to remove excess material from the blank—all automated, with precision up to ±0.005 mm (thinner than a human hair). Common operations here include milling (shaping), 掘削 (穴), and turning (cylindrical parts).

- 後処理: 機械加工後, the prototype may have rough edges or uneven surfaces. Post-processing fixes this:

- クリーニング: Remove metal chips and oil with ultrasonic cleaners.

- Deburring: Smooth sharp edges with hand tools or automated deburring machines.

- Heat Treatment: Strengthen the metal (例えば。, annealing for aluminum to reduce brittleness).

- Surface Finishing: Add coatings like anodizing (for aluminum) or powder coating (for steel) to improve appearance and durability.

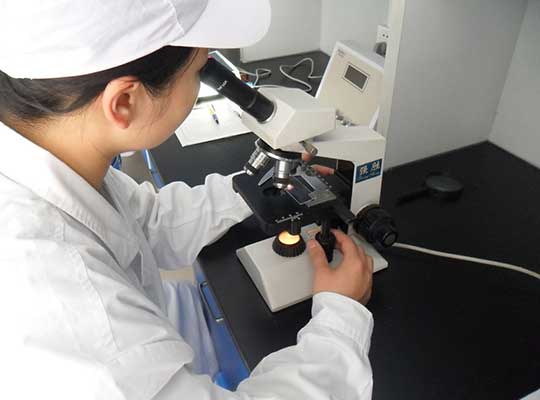

- Quality Inspection: Use tools like coordinate measuring machines (CMMs) or 3D scanners to check if the prototype meets design specs. This ensures dimensions, surface smoothness, and fit are accurate—critical for validating your design.

3. Why Choose CNC Metal Prototype Processing? 4 重要な利点

CNC metal prototype processing stands out from other methods (例えば。, 3D印刷) for several reasons—especially when precision and realism matter. Here are its top benefits:

- 高精度 & Repeatability: CNC machines follow code with minimal human error, so every prototype is identical. This is vital for testing fit (例えば。, how two parts connect) and ensuring consistency. Most CNC prototypes meet tolerance levels of ±0.01 mm, which is essential for industries like aerospace and medical.

- Realistic Material Simulation: Unlike 3D-printed prototypes (which use plastics or resins), CNC prototypes use the same metal as your final product. This lets you test real-world performance—like how a stainless steel part resists corrosion or how a titanium part handles stress—before production.

- Superior Surface Quality: CNC machining creates smooth, finished surfaces (RA値は低いです 0.8 μm) without extra work. This is perfect for products where appearance matters, like consumer electronics or luxury goods.

- Easy Design Iteration: If your prototype fails a test (例えば。, a part breaks under pressure), you can quickly modify the CNC program—no need to rebuild tools or molds. This cuts down iteration time by 30–50% compared to traditional manufacturing.

4. Who Uses CNC Metal Prototype Processing? Key Industries

CNC metal prototype processing is a backbone of product development across industries. Here are the sectors that rely on it most:

- 航空宇宙: Test lightweight, high-strength parts (例えば。, turbine blades) before putting them in planes.

- Medical: Validate biocompatible parts (例えば。, 手術ツール, implants) to meet strict safety standards.

- 自動車: Check how parts (例えば。, engine components, ブラケット) perform under heat and stress.

- 家電: Refine the design of metal casings (例えば。, laptops, smartwatches) for fit and look.

- Industrial Machinery: Test durable parts (例えば。, ギア, バルブ) to ensure they work in harsh conditions.

Yigu Technology’s Perspective on CNC Metal Prototype Processing

Yiguテクノロジーで, we believe CNC metal prototype processing is the bridge between great designs and successful products. It solves a key pain point for our clients: reducing the risk of costly mistakes in full-scale production. We’ve seen clients cut 研发 time by 40% and avoid expensive reworks by testing CNC metal prototypes first. For businesses focused on quality and speed, CNC metal prototypes aren’t just an option—they’re a necessity. Our team uses advanced CNC machines to deliver prototypes with ±0.005 mm precision, helping clients turn ideas into reliable products faster.

FAQ About CNC Metal Prototype Processing

- How long does it take to make a CNC metal prototype?

It depends on the part’s complexity and size. Simple parts (例えば。, a small bracket) can take 1–3 days, while complex parts (例えば。, a medical implant) may take 5–7 days. 後処理 (例えば。, heat treatment) can add 1–2 extra days.

- Is CNC metal prototype processing more expensive than 3D printing?

For small, 単純な部品, 3D printing may be cheaper. But for complex, high-precision metal parts, CNC machining is often more cost-effective—especially if you need to test material performance. CNC also avoids the need for extra post-processing (例えば。, strengthening) that 3D-printed parts often require.

- Can CNC metal prototypes be used for small-batch production?

はい! If you need 10–100 parts (例えば。, for beta testing or niche markets), CNC machining is a great option. It’s faster than setting up molds for traditional production and still cost-effective for small runs.