Choosing the right manufacturing process is critical for product success, whether you’re prototyping a new design or scaling up production. Two popular methods—CNC加工 そして 反応射出成形 (RIM)—offer distinct advantages depending on your project’s needs. This guide breaks down their differences in processes, パフォーマンス, 費用, and applications to help you make informed decisions.

Understanding the Core Manufacturing Processes

The fundamental difference between CNC machining and RIM lies in how they shape materials to create parts.

How CNC Machining Works

CNC加工 is a subtractive manufacturing process that starts with a solid block of material—such as metal, プラスチック, or composite—and removes excess material using computer-controlled cutting tools. The process follows these steps:

- A CAD (コンピューター支援設計) file is created to define the part’s dimensions.

- CAM (コンピューター支援の製造) software converts the design into machine-readable code (Gコード).

- The CNC machine uses tools like end mills and drills to cut, drill, and shape the material according to the code.

- Finishing processes like grinding or polishing may be added to achieve the desired surface quality.

This method is ideal for creating precise, complex parts with tight tolerances, making it a staple in industries like aerospace and medical device manufacturing.

How Reaction Injection Molding (RIM) Works

反応射出成形 (RIM) is an additive process that relies on chemical reactions to form parts. The steps are:

- Two liquid components—typically polyols and isocyanates—are mixed under low pressure.

- The mixture is injected into a mold cavity where it undergoes a chemical reaction, expanding and solidifying.

- 硬化後, the mold opens, and the finished part is ejected.

- Minimal post-processing is usually required, especially for parts with simple geometries.

RIM is primarily used for producing plastic and polyurethane parts, offering advantages in creating large, lightweight components.

Performance Comparison: 精度, 強さ, and Versatility

When evaluating manufacturing processes, performance characteristics directly impact part quality and suitability for specific applications.

CNC Machining Performance Highlights

- Tight Tolerances: CNC machining achieves tolerances as tight as ±0.001 inches (0.025 mm), making it ideal for critical components where precision is non-negotiable.

- 物質的な汎用性: It works with a wide range of materials, 金属を含む (アルミニウム, 鋼鉄, 真鍮), プラスチック (腹筋, ナイロン), および複合材料.

- 複雑なジオメトリ: The subtractive process excels at creating intricate external features and detailed surface textures.

- 表面仕上げ: Produces high-quality surface finishes (Ra 0.8–3.2 μm) with minimal post-processing required.

RIM Performance Highlights

- 公差: RIM typically achieves tolerances of ±0.005 inches (0.127 mm), suitable for many industrial applications but not ultra-precision parts.

- Material Properties: Creates lightweight parts with good durability and chemical resistance, particularly in polyurethane formulations.

- Large Part Production: Ideal for manufacturing large components (up to several feet in size) with consistent wall thickness.

- 設計の柔軟性: Allows for complex internal cavities and undercuts that may be challenging with CNC machining.

Cost Analysis: Initial Investment vs. 長期節約

Cost considerations play a significant role in choosing between CNC machining and RIM, with each process offering different cost structures based on production volume.

CNC Machining Cost Factors

- Tooling Costs: Lower upfront tooling costs (\(500- )5,000) compared to molding processes, as it primarily requires fixtures and cutting tools.

- Per-Part Costs: Higher per-part costs (\(5- )50+) due to longer cycle times and material waste from subtractive manufacturing.

- Economies of Scale: Less cost-effective for high-volume production (10,000+ ユニット) as per-part costs remain relatively stable.

- Setup Time: Faster setup times (1–3日) reduce initial production delays.

RIM Cost Factors

- Tooling Costs: Moderate tooling costs (\(5,000- )50,000) for mold creation, which are lower than traditional injection molding but higher than CNC machining.

- Per-Part Costs: Lower per-part costs (\(1- )10) for high-volume runs due to faster cycle times and material efficiency.

- Economies of Scale: Becomes more cost-effective than CNC machining for production volumes exceeding 1,000 ユニット.

- Setup Time: Longer initial setup (2–6週) due to mold design and fabrication.

| 生産量 | CNC Machining Total Cost | RIM Total Cost |

| 100 ユニット | \(5,000- )15,000 | \(10,000- )30,000 |

| 1,000 ユニット | \(20,000- )60,000 | \(15,000- )40,000 |

| 10,000 ユニット | \(150,000- )500,000 | \(30,000- )150,000 |

Feature Comparison: 材料, Design, and Production Capabilities

The unique features of each process determine their suitability for different project requirements.

Material Capabilities

- CNC加工: Supports metals (アルミニウム, 鋼鉄, チタン), プラスチック (PE, pp, ピーク), composites, and even wood. This versatility makes it ideal for projects requiring material-specific properties like high strength or heat resistance.

- RIM: Limited to plastic and polyurethane materials, including flexible and rigid formulations. While restricted, these materials offer excellent impact resistance and insulation properties.

設計の柔軟性

- CNC加工: Easily accommodates design changes with minimal cost, as modifications only require updating the CAD file and machine program. This makes it perfect for prototyping and iterative design processes.

- RIM: Design changes require mold modifications, which can be costly and time-consuming. It’s better suited for finalized designs with stable requirements.

Production Volume and Speed

- CNC加工: Best for low to medium volumes (1–1,000 units) with longer per-part cycle times (minutes to hours).

- RIM: Excels at medium to high volumes (1,000–100,000+ units) with faster cycle times (seconds to minutes per part).

アプリケーションシナリオ: Choosing the Right Process

Understanding which process works best for specific applications helps optimize production efficiency and part quality.

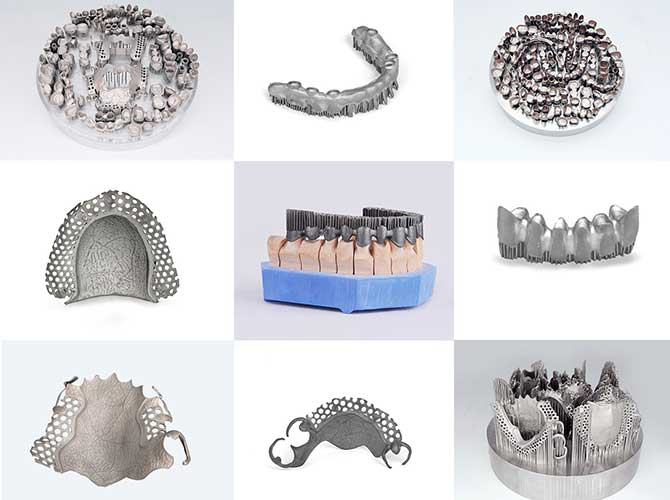

Ideal Applications for CNC Machining

- プロトタイピング: Quick turnaround for design validation without expensive tooling.

- High-Precision Parts: 航空宇宙コンポーネント, 医療機器, and automotive sensors requiring tight tolerances.

- Low-Volume Production: Custom machinery parts or specialized industrial components with small production runs.

- Metal Components: Parts requiring the strength and durability of metals like stainless steel or titanium.

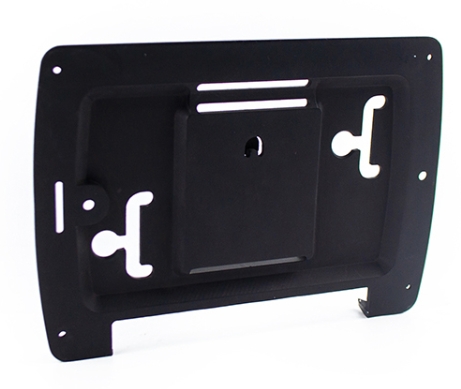

Ideal Applications for RIM

- Large Plastic Parts: Automotive bumpers, 産業エンクロージャー, and recreational equipment housings.

- Lightweight Components: Parts where weight reduction is critical, such as drones or portable equipment.

- Consistent High-Volume Production: Consumer goods and appliance parts needing uniform quality at scale.

- Elastic or Flexible Parts: Gaskets, アザラシ, and ergonomic components requiring specific material elasticity.

Yigu Technologyの視点

Yiguテクノロジーで, we believe the choice between CNC machining and RIM depends on balancing precision, volume, および物質的なニーズ. For prototypes or high-precision metal parts, CNC machining delivers unbeatable accuracy. For large-volume plastic components, RIM offers cost efficiency and scalability. Our engineering team works closely with clients to select the optimal process, ensuring each project meets performance goals and budget requirements.

よくある質問 (よくある質問)

- When should I choose CNC machining over RIM?

Choose CNC machining for low-volume production, 高精度部品, metal components, or projects requiring frequent design changes. Its lower upfront costs and material versatility make it ideal for prototyping and specialized applications.

- Is RIM more cost-effective than CNC machining for large production runs?

はい, RIM becomes more cost-effective for production volumes over 1,000 ユニット. While RIM has higher initial tooling costs, its lower per-part costs and faster cycle times create significant savings at scale compared to CNC machining.

- Can RIM produce parts with the same precision as CNC machining?

いいえ, RIM typically achieves tolerances of ±0.005 inches, while CNC machining can reach ±0.001 inches. For applications requiring ultra-tight tolerances or complex geometric details, CNC machining is the better choice despite its higher per-part costs.