製品開発中の場合, you know that creating prototypes is a crucial step before mass production. しかし、非常に多くのオプションが利用可能です, how do you choose the right prototype processing method for your project? このガイドで, 分解します 8 most common rapid prototyping techniques, comparing their processes, 材料, 強み, and weaknesses to help you make informed decisions.

Why Rapid Prototyping Matters in Modern Manufacturing

Rapid prototyping has revolutionized product development across industries. Gone are the days of time-consuming papier-mache models or expensive one-off prototypes that took weeks to create. Today’s rapid prototyping methods offer faster turnaround times, better accuracy, and more cost-effective solutions—essential advantages in competitive markets where companies that skip this step quickly fall behind.

But with so many techniques available, each with its own set of capabilities, it’s important to understand which method aligns best with your project’s requirements. Let’s dive into the 8 most popular options.

1. ステレオリスム造影 (SLA)

ステレオリスム造影, commonly known as SLA, was one of the first 3D printing technologies developed and remains a popular choice for rapid prototyping.

How SLA Works

SLA is an additive manufacturing process that uses a liquid photopolymer resin cured layer by layer with an ultraviolet (UV) レーザ. After the laser scans each layer to form the model, the finished prototype is placed in a UV oven for final curing to maintain its shape.

Key Features of SLA

- 材料: Liquid photopolymer resins

- 正確さ: High precision with fine details

- 表面仕上げ: Smooth textures ideal for painting or finishing

- 後処理: Requires UV oven curing after printing

- Printer Size: Varied sizes, with larger printers capable of producing bigger models

Advantages of SLA

- Exceptional accuracy for detailed prototypes

- Relatively affordable compared to some other 3D printing methods

- Smooth surface finish reduces post-processing needs

- Good heat resistance for certain applications

Limitations of SLA

- Models lack high structural strength

- UV light and moisture can degrade the resin over time

- Not ideal for prototypes needing to withstand significant strain

- Requires careful handling of liquid resin materials

2. Fused Deposition Modelling (FDM)

Fused Deposition Modelling (FDM) is likely the most recognizable 3D printing technology, widely used in homes, schools, そして中小企業.

How FDM Works

FDM uses thermoplastic filament spools fed into a heated nozzle, where the plastic is melted and extruded onto a print bed. The model is built layer by layer from the bottom up, with each layer bonding to the previous one as it cools.

Key Features of FDM

- 材料: Thermoplastic filaments (プラ, 腹筋, PETG, 等)

- 料金: Affordable machines and materials

- スピード: Relatively fast printing times for small to medium models

- Support Structures: Requires additional support structures for overhangs

Advantages of FDM

- Most cost-effective 3D printing option available

- Simple operation makes it accessible for beginners

- Wide range of available materials in various colors

- Fast turnaround for basic prototypes

- Portable machines available for on-site prototyping

Limitations of FDM

- Lower durability compared to other methods

- Surface finish tends to be rougher without post-processing

- Layer lines are visible in the final product

- Requires careful setup of support structures to prevent sagging

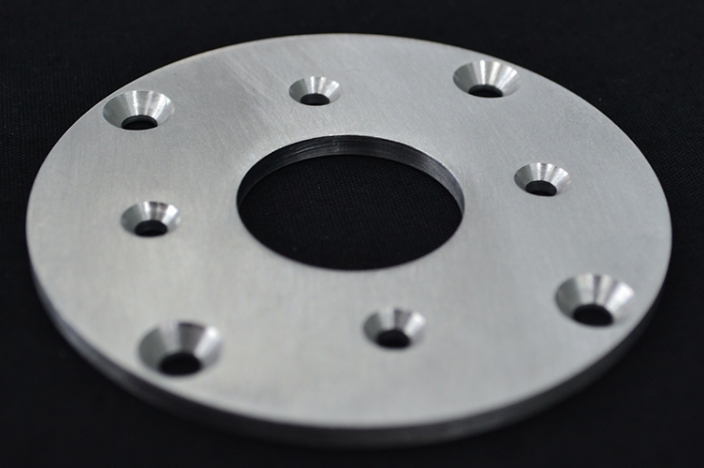

3. CNC加工

Unlike additive methods that build models layer by layer, CNC machining uses a subtractive approach to create prototypes.

How CNC Machining Works

CNC (Computer Numerically Controlled) machining starts with a solid block (rod stock) of plastic or metal clamped into a lathe or mill. Computer-controlled tools move along multiple axes to precisely remove material from the block, shaping it into the desired prototype.

Key Features of CNC Machining

- 材料: プラスチック, 金属, 木材, and various composites

- プロセス: Subtractive manufacturing (removes material from a solid block)

- 正確さ: High precision with tight tolerances

- 表面仕上げ: Can achieve highly polished results

Advantages of CNC Machining

- Exceptional structural strength since prototypes are made from solid material

- No layer lines, maintaining material integrity

- Can produce prototypes with complex geometries

- Often used for finishing touches on prototypes made with other methods

- Suitable for both plastic and metal prototypes

Limitations of CNC Machining

- More material waste compared to additive methods

- Less cost-effective for highly complex designs

- Generally slower than 3D printing for small, intricate parts

- Requires skilled operators for programming and setup

4. 選択的レーザー焼結 (SLS)

選択的レーザー焼結 (SLS) offers a middle ground between SLA and traditional manufacturing, using powdered materials instead of liquid resin.

How SLS Works

SLS uses a CO2 laser to fuse layers of powdered material (typically plastic) together. The laser “draws” each layer of the model in the powder bed, sintering (fusing) the particles to form solid sections. Unlike SLA, no post-printing curing in an oven is required.

Key Features of SLS

- 材料: ポリアミド (ナイロン) powders and other polymers

- 正確さ: Good precision with fine details

- Structural Integrity: 強い, functional prototypes

- Support Structures: Not required due to surrounding powder support

Advantages of SLS

- Creates strong, functional prototypes

- Parts have isotropic mechanical characteristics (uniform strength in all directions)

- No need for support structures during printing

- Can produce complex geometries

- Suitable for functional testing

Limitations of SLS

- Surface finish is not as smooth as SLA

- No transparent material options

- Materials can be more difficult to source

- Higher equipment costs compared to FDM

5. Direct Metal Laser Sintering (DMLS)

For metal prototypes that need to withstand heavy use, Direct Metal Laser Sintering (DMLS) is the go-to technology.

How DMLS Works

DMLS operates on the same principle as SLS but uses powdered metals instead of polymers. A high-powered laser fuses metal particles together layer by layer to create fully dense metal prototypes.

Key Features of DMLS

- 材料: アルミニウム, ステンレス鋼, チタン, Inconel, maraging steel, cobalt chrome

- 密度: Produces fully dense metal parts (99.9% density)

- 後処理: Often requires heat treatment or machining for final finish

Advantages of DMLS

- Creates strong metal prototypes suitable for functional testing

- Can produce complex geometries impossible with traditional machining

- Works with a wide range of metal alloys

- Ideal for final-stage prototypes before production

- Parts can be used as production units in some cases

Limitations of DMLS

- High equipment and material costs

- Relatively slow printing process

- Requires post-processing for optimal results

- Best suited for industrial applications due to cost

6. Multi Jet Fusion (MJF)

Multi Jet Fusion (MJF) is a newer technology that combines speed with strength for functional prototypes.

How MJF Works

MJF uses a print head to apply a fusing agent onto layers of powdered material, which is then fused by passing a fuser over the bed. This process repeats layer by layer until the prototype is complete. 印刷後, parts undergo bead blasting to remove excess powder and can be dyed if needed.

Key Features of MJF

- 材料: Various polymers, notably TPUM95A

- スピード: Faster than SLS for comparable parts

- 正確さ: Good precision with consistent quality

- 表面仕上げ: Smooth with minimal post-processing needed

Advantages of MJF

- Fast production of strong functional prototypes

- Suitable for limited production runs beyond prototyping

- High productivity (まで 250 small to medium models daily)

- Consistent part quality across builds

- No need for support structures

Limitations of MJF

- More limited material options compared to other methods

- Higher initial investment in equipment

- Not as widely available as FDM or SLA

- Requires specialized knowledge for optimal results

7. PolyJet (PJET) プロトタイピング

PolyJet technology offers exceptional detail for visual prototypes and concept models.

How PolyJet Works

PolyJet uses a print head to spray layers of photopolymer resin onto a build platform, which are immediately cured with UV light. This layer-by-layer process continues until the model is complete, with layers as thin as 0.032mm for incredible detail.

Key Features of PolyJet

- 材料: Photopolymer resins in various types (rigid, フレキシブル, 透明)

- Resolution: Extremely fine details with thin layers

- 表面仕上げ: Smooth, ready-to-use without extensive post-processing

- 硬化: Fully cured during printing, no post-printing curing needed

Advantages of PolyJet

- Highest resolution among rapid prototyping methods

- Exceptional detail for visual models

- Smooth surface finish right off the printer

- Can combine multiple materials in a single print

- Ideal for architectural models and visual prototypes

Limitations of PolyJet

- Materials lack high structural strength

- Not suitable for functional testing under strain

- Higher material costs compared to FDM

- Limited part size due to printer constraints

8. Rapid Injection Moulding

Rapid Injection Moulding brings traditional manufacturing benefits to the prototyping stage with faster turnaround times.

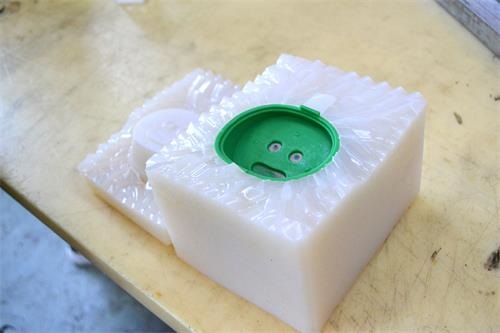

How Rapid Injection Moulding Works

Similar to traditional injection moulding, this process injects thermoplastic resins into a pre-made mould to form the prototype. The key difference is the use of aluminum moulds instead of stainless steel, making mould creation faster and more affordable.

Key Features of Rapid Injection Moulding

- 材料: Wide range of thermoplastic resins

- プロセス: Injection of molten plastic into reusable moulds

- 音量: Suitable for small to medium production runs

- Finish: Consistent, high-quality surface finish

Advantages of Rapid Injection Moulding

- Produces prototypes that closely mimic final production parts

- More cost-effective than traditional injection moulding for prototyping

- Suitable for functional testing of final designs

- Can produce multiple identical prototypes efficiently

Limitations of Rapid Injection Moulding

- Still more expensive than 3D printing for single prototypes

- Not practical for in-house use by most businesses

- Best used after design confirmation with other prototyping methods

- Mould modifications are possible but add time and cost

Comparison Table: 8 Prototype Processing Methods

| 方法 | Key Advantage | Primary Limitation | に最適です | Material Types | コストレベル |

| SLA | High accuracy, smooth finish | Low strength | Detailed visual prototypes | Photopolymer resins | 中くらい |

| FDM | Affordable, easy to use | Lower durability, rough finish | Basic prototypes, concept models | Thermoplastic filaments | 低い |

| CNC加工 | 高強度, solid material | Material waste, slower | Functional metal/plastic parts | 金属, プラスチック, 木材 | 中程度 |

| SLS | Strong functional parts | Rough surface, limited materials | Durable prototypes, 機能テスト | Nylon and polymer powders | 中程度 |

| DMLS | Strong metal prototypes | High cost, slow process | Metal functional parts, end-use parts | Metal alloys | 高い |

| MJF | Fast production, strong parts | Limited materials | Medium-volume prototyping | TPUM95A and other polymers | 中程度 |

| PolyJet | Exceptional detail | Low strength | Visual models, detailed concepts | Photopolymer resins | 高い |

| Rapid Injection Moulding | Production-like parts | Higher cost, mould required | Final-stage prototypes, small runs | Thermoplastic resins | 中程度 |

Yigu Technologyの視点

Yiguテクノロジーで, we believe choosing the right prototype processing method depends on balancing accuracy, 強さ, 料金, and turnaround time. For early-stage concepts, FDM offers affordability, while SLA provides better detail. As projects advance, CNC machining and SLS deliver stronger functional parts, with DMLS excelling for metal components. We recommend combining methods—using 3D printing for initial designs and CNC or injection moulding for final prototypes—to optimize development efficiency.

よくある質問:

- Which prototype processing method is the most affordable?

FDM is generally the most affordable option, with relatively inexpensive machines and materials, making it ideal for beginners and basic prototyping needs.

- What’s the best method for creating functional metal prototypes?

Direct Metal Laser Sintering (DMLS) is the top choice for functional metal prototypes, as it can produce strong, fully dense metal parts using various alloys.

- How do I choose between additive and subtractive prototyping methods?

Additive methods (like SLA, FDM) work best for complex geometries and faster turnaround, while subtractive methods (like CNC machining) excel at producing strong, precise parts from solid materials, though with more material waste.