If you’re looking to create prototypes with a soft, light – diffusing look rather than full transparency, you might be wondering about using translucent resin for 3D printing. 答えは明確なはいです! Translucent resin is a fantastic option for 3D printed prototypes, offering a unique blend of aesthetics and functionality. Let’s explore how to make the most of translucent resin in your 3D printing projects.

Why Translucent Resin is Great for 3D Printing Prototypes

Translucent resin has quickly become a favorite among prototype makers, and it’s easy to see why. Its special properties make it perfect for certain types of projects.

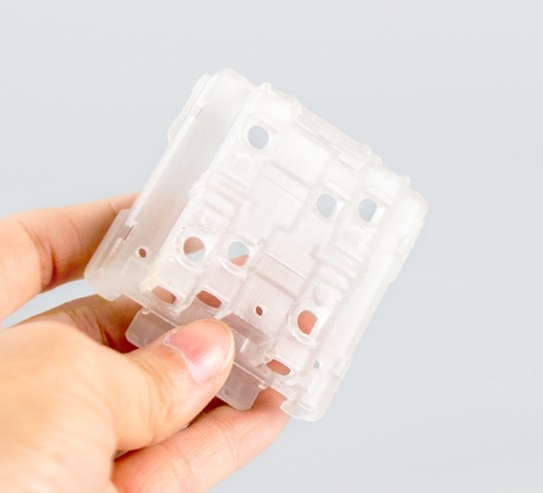

- Natural light diffusion is its standout feature. Unlike fully transparent materials that let light pass through clearly, translucent resin scatters light gently, creating a soft, frosted appearance. This makes it ideal for prototypes like light covers, lamp shades, or any part where a warm, diffused glow is desired.

- Reduced post – processing needs save time and effort. Translucent resin prints with a naturally smooth surface, so you won’t need as much sanding or polishing compared to other materials. This is a big plus when you’re working on tight deadlines or need to produce multiple prototype iterations quickly.

- Versatile aesthetic appeal works across industries. Whether you’re prototyping consumer electronics, 医療機器, or decorative items, the subtle translucency adds a professional, 高い – end look that plain opaque materials can’t match.

Choosing the Right Translucent Resin: What to Look For

Not all translucent resins are the same, so picking the right one for your prototype is key to success. Here are the important factors to consider:

- Optical properties should top your list. Look for resins specifically formulated for translucency, such as RAYSHAPE’s Clear 10 樹脂, which is known for its excellent light – diffusing qualities. These resins are designed to maintain consistent translucency across the entire part, avoiding patchy or uneven areas.

- Printer compatibility is a must – check. Translucent resins are typically used with SLA (ステレオリスム造影) or DLP (Digital Light Processing) printers, which use UV light to cure the resin. Always confirm that the resin you choose works with your printer’s wavelength and curing system to avoid printing issues.

- 材料の一貫性 matters for reliable results. 高い – quality translucent resins have a uniform viscosity, which helps ensure smooth printing and consistent layer adhesion. Avoid resins that are too thick or have particles floating in them, as these can cause clogs or uneven prints.

役職 – Processing Tips for Translucent Resin Prototypes

While translucent resin requires less post – processing than some other materials, a little extra work can take your prototype to the next level.

- Light polishing enhances smoothness. Even though the printed surface is already smooth, a quick polish with a soft cloth or 800 – grit sandpaper can remove any minor layer lines and boost the resin’s light – diffusing properties. Be gentle – you don’t want to over – sand and create scratches that would scatter light unevenly.

- Oil spraying adds a subtle finish. A light coat of clear oil spray can enhance the translucency while protecting the surface from scratches. This step is especially useful if your prototype will be handled frequently during testing or presentations.

- Avoid heavy sanding. Unlike transparent resin, which benefits from aggressive sanding to achieve clarity, translucent resin’s beauty lies in its soft texture. Too much sanding can make the surface too smooth, reducing its ability to diffuse light effectively.

Important Printing Environment Considerations

The environment where you print with translucent resin can affect both the quality of your prototype and its longevity, especially for more complex designs.

- Humidity control is crucial, especially for prototypes with cavities or hollow sections. Moisture trapped inside these spaces can cause the prototype to crack or even burst as the humidity inside and outside the part equalizes over time. Keep your printing area’s humidity below 50% and make sure any hollow parts are completely dry before and after printing.

- Dust protection is essential. Even small dust particles are more visible on translucent surfaces than on opaque ones. Keep your printer and workspace clean, use a dust cover when the printer isn’t in use, and handle printed parts with clean gloves to avoid leaving fingerprints or smudges that would mar the translucent effect.

Creating Custom Effects with Translucent Resin

One of the best things about translucent resin is its ability to be customized with color while maintaining its light – diffusing properties. Here’s how to do it:

- Mix with colored resins for unique shades. If you want a colored translucent prototype, try mixing a small amount of colored resin with your translucent resin. 例えば, adding a touch of black resin creates a sleek, smoky translucent effect that still allows light to pass through. Start with a 10:1 ratio of translucent to colored resin and adjust until you get the look you want.

- Test mixtures first. Always print a small sample with your resin mixture before starting on your main prototype. This lets you check the color intensity and translucency level, saving you time and material if you need to adjust the ratio.

- Stir thoroughly for even color. When mixing resins, take your time to stir them completely. Uneven mixing can result in streaks or spots in your prototype, which are more noticeable in translucent materials than in opaque ones.

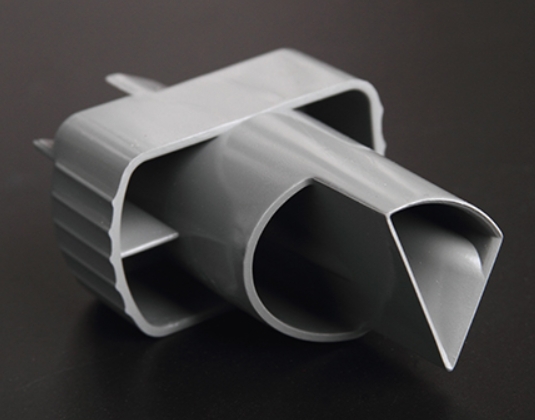

Translucent Resin vs. Transparent Resin: Knowing the Difference

It’s easy to confuse translucent and transparent resins, しかし、それらはさまざまなプロジェクトに適した明確なプロパティを持っています. 簡単な比較です:

| 側面 | 半透明の樹脂 | Transparent Resin |

| 光伝達 | 拡散して柔らかく拡散します; 完全に明確ではありません | 光がはっきりと通過できるようにします |

| 役職 – 処理ニーズ | 最小限; 軽い磨きのみ | より広範です; サンディングとバフを必要とします |

| に最適です | 光カバー, 装飾的な部分, 拡散したグロー効果 | レンズ, クリアウィンドウ, 明確さを必要とする部品 |

| 美的 | 霜, 柔らかい外観 | ガラス – のように, 透明な外観 |

- それらを選択することは、プロトタイプのニーズに依存します. 光を拡散させるか、微妙な部分が必要な場合, エレガントな外観, 半透明の樹脂が行く方法です. 真の明確さが必要な場合, レンズやクリアウィンドウのように, 代わりに透明な樹脂を選択してください.

半透明の樹脂の印刷設定を最適化します

半透明の樹脂で最良の結果を得るため, 印刷設定をいくつか調整すると、大きな違いが生じる可能性があります:

- 層の厚さ 表面の滑らかさに影響します. の層の厚さ 20 – 30 ミクロンは、ほとんどの半透明の樹脂プロトタイプでうまく機能します. これにより、印刷速度と表面品質のバランスが取れます。薄いレイヤーはより滑らかな表面を作成しますが、印刷に時間がかかります, より厚い層はより速く印刷しますが、より多くのレイヤーラインが表示される場合があります.

- 曝露時間 慎重に調整する必要があります. 樹脂製造業者の推奨される暴露時間に従ってください, 下のように – 曝露は、不均一な半透明の弱い部分につながる可能性があります, 終わっている間 – 曝露により、樹脂が望ましいよりも不透明になります. 異なる露出時間のクイックテストプリントは、スイートスポットを見つけるのに役立ちます.

- 印刷速度 impacts detail retention. Translucent resin prints best at moderate speeds (40 – 60 mm/s for most printers). Printing too fast can cause layer adhesion issues, while printing too slow may lead to over – curing.

Yigu Technology’s View

Translucent resin is a versatile choice for 3D printed prototypes, offering unique light diffusion and reduced post – processing. Its ability to create soft, professional finishes makes it ideal for diverse applications. Yiguテクノロジーで, we recommend focusing on quality resin selection, humidity control, and gentle post – その可能性を最大化するための処理, 見事なことを保証します, 毎回機能的なプロトタイプ.

よくある質問

- 透明な樹脂よりも透明な樹脂が印刷しやすいですか?

はい, 半透明樹脂は一般に必要なポストが少なくなります – 自然に滑らかな表面のために処理し、その希望の外観を実現するために広範なサンディングは必要ありません, より多くのユーザーにします – フレンドリー.

- 機能テストには半透明の樹脂プロトタイプを使用できます?

絶対に. 多くの半透明の樹脂は、良好な機械的強度を提供します, それらをテストフォームに適しています, フィット, および基本機能, 彼らは高に理想的ではないかもしれませんが – ストレス構造部分.

- 半透明の樹脂プロトタイプの水分の問題を防ぐにはどうすればよいですか?

印刷環境の湿度を制御します (下に置いてください 50%), 印刷前後に中空の部品が完全に乾燥していることを確認してください, クラッキングや破裂を避けるために、完成したプロトタイプを乾燥したエリアに保存します.