When creating mold replication models—whether for industrial prototypes, statue artistiche, o parti funzionali: la scelta del materiale giusto influisce direttamente sulla precisione del modello, durabilità, e costo. This article breaks down the most widely used materials for mold replication models, i loro tratti chiave, scenari applicativi, e metodi operativi passo passo per aiutarti a fare la scelta ottimale.

1. Core Materials for Mold Replication Models: Confronto a colpo d'occhio

To quickly evaluate which material fits your project, start with this comprehensive comparison table. It highlights each material’s advantages, limitazioni, and typical uses—saving you time in preliminary selection.

| Materiale | Core Advantages | Key Limitations | Typical Replication Model Applications |

| Silicone | High temperature resistance, resistenza alla corrosione, strong tear resistance, high replication precision | Higher cost than gypsum; requires ratio mixing | Mannequins, mechanical parts, ricambi auto, silicone dolls, figure prototypes |

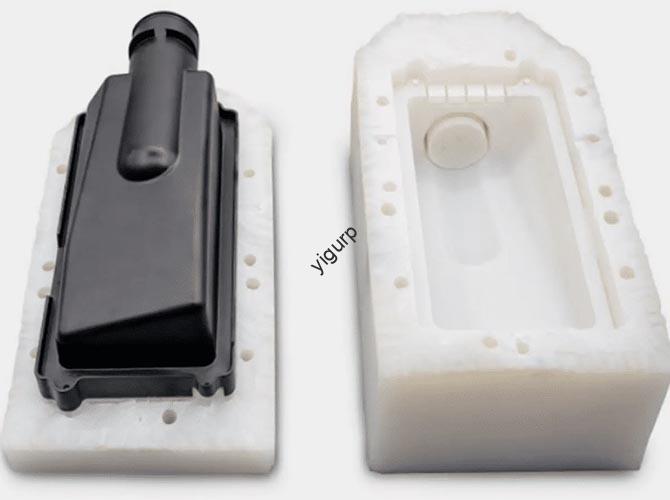

| Gypsum | Basso costo, simple operation, easy cleaning, high rigidity/hardness | Poor impact resistance; low temperature tolerance | Silicone model shells, simple decorative replicas, low-precision structural supports |

| Resin (Unsaturated/Epoxy) | High strength, elevata tenacità, resistenza all'usura, resistenza alla corrosione, alta precisione | Longer curing time; toxic fumes (without proper ventilation) | High-end figures, statues, detailed auto parts, prototipi industriali |

| Hot Melt Adhesive | Strong toughness, good shape retention, bendable without damage | Low heat resistance; limited precision for fine details | Small decorative replicas, temporary prototypes, low-stress functional parts |

2. Detailed Breakdown of Each Replication Material

Below is an in-depth analysis of each material, using a “trait + operation + scenario” structure to link technical features to real-world use cases. This helps you understand why E Come to use each material for your model.

2.1 Silicone: The Precision Choice for High-Detail Replicas

Why is silicone a top pick for mold replication models? Its four unrivaled traits make it ideal for capturing fine details:

- High replication precision: Silicone can replicate even tiny surface textures (per esempio., 0.1mm grooves on a mechanical part) without distortion. This is critical for making accurate auto part prototypes or figure prototypes, where detail fidelity directly affects the model’s usability.

- Extreme durability: With high temperature resistance (up to 200–300°C depending on grade) E resistenza alla corrosione, silicone models withstand harsh environments—perfect for testing industrial parts that may encounter heat or chemicals.

- Strong tear resistance: Unlike fragile materials like gypsum, silicone models won’t tear easily during demolding or handling, reducing waste in production.

How to Use Silicone for Replication:

- Prepare two components of silicone (usually labeled A and B) and mix them in a 1:1 ratio (check the product manual for exact proportions).

- Add the recommended amount of curing agent and stir thoroughly to avoid air bubbles.

- Pour the mixture into the prepared mold cavity, ensuring it covers all details.

- Wait for the silicone to cure (typically 4–8 hours at room temperature; faster with heat).

Common Scenarios: Industrial mechanical part prototypes, high-end silicone dolls, life-sized mannequins, detailed auto part replicas.

2.2 Gypsum: The Budget-Friendly Option for Simple Replicas

Gypsum shines when cost and ease of use are priorities. Its key benefits address the needs of beginners or low-budget projects:

- Basso costo: Gypsum powder is significantly cheaper than silicone or resin, making it ideal for large-scale but low-precision models (per esempio., a 1m-tall decorative statue shell).

- Easy operation: No complex ratio mixing or special equipment is needed—even those new to mold replication can master it quickly.

- Strong structural support: Its high rigidity and hardness make it perfect for creating shells for silicone models (per esempio., a gypsum outer shell to reinforce a soft silicone mannequin).

How to Use Gypsum for Replication:

- Mix gypsum powder and clean water in a 2:1 ratio (by weight) to form a smooth paste (adjust consistency if needed—too thin = longer drying; too thick = air bubbles).

- Press the original model into the gypsum paste gently, ensuring the paste covers the model’s surface evenly.

- Let the gypsum dry completely (6–12 hours at room temperature; avoid direct sunlight to prevent cracking).

- Carefully remove the original model to reveal the gypsum replication mold.

Common Scenarios: Silicone model outer shells, simple decorative replicas (per esempio., small statues), school project prototypes.

2.3 Resin: The Durable Choice for High-Performance Models

Resin (including unsaturated resin and epoxy resin) is the go-to for replication models that need strength and precision. Its standout traits include:

- High mechanical performance: Resin models have alta resistenza E tenacità, making them suitable for functional prototypes (per esempio., a test version of an auto part that needs to withstand pressure).

- Wear and corrosion resistance: Unlike gypsum, resin models won’t chip easily or degrade when exposed to mild chemicals—ideal for long-term use or outdoor displays (with proper coating).

- Versatility: Different resin types serve different needs:

- Unsaturated resin: Faster curing (1–2 hours) and lower cost, good for general-purpose replicas.

- Epoxy resin: Higher precision and stronger bonding, perfect for high-end figures or industrial parts requiring tight tolerances.

How to Use Resin for Replication:

- For unsaturated/epoxy resin, mix the two components (A = resin, B = hardener) in the recommended ratio (usually 10:1 for unsaturated, 2:1 for epoxy).

- Stir the mixture slowly to avoid creating air bubbles (use a vacuum chamber if available for high-precision models).

- Pour the resin into the mold and let it cure (unsaturated resin: 1–2 hours; epoxy resin: 4–6 hours).

- Demold and sand the surface for a smooth finish if needed.

Common Scenarios: High-end collectible figures, detailed statues, industrial auto part prototypes, corrosion-resistant mechanical components.

2.4 Hot Melt Adhesive: The Quick-Fix for Small, Flexible Replicas

Hot melt adhesive is a practical choice for small-scale or temporary mold replication models. Its key advantages are:

- Fast turnaround: No curing time—just heat, pour, and cool (10–15 minutes total), making it great for urgent prototype needs.

- Strong shape retention: Once cooled, hot melt adhesive models maintain their shape and can be bent hard without breaking—ideal for parts that need minor flexibility (per esempio., a small toy component).

- Low cost and accessibility: Hot melt adhesive sticks are cheap and widely available at hardware stores, no specialized materials required.

How to Use Hot Melt Adhesive for Replication:

- Heat a hot melt adhesive gun until the adhesive is fully melted (typically 150–180°C).

- Slowly squeeze the melted adhesive into the mold cavity, filling all gaps without overpouring.

- Let the adhesive cool to room temperature (5–10 minutes) until it hardens.

- Gently remove the model from the mold—no additional curing steps needed.

Common Scenarios: Small decorative replicas (per esempio., keychain charms), temporary prototypes for design testing, low-stress toy parts.

3. Yigu Technology’s View on Materials for Mold Replication Models

Alla tecnologia Yigu, we believe the best material for mold replication models depends on three factors: project precision needs, bilancio, and end-use environment. For high-detail industrial parts, silicone or epoxy resin is unbeatable; for low-cost simple shells, gypsum works best; for small urgent projects, hot melt adhesive saves time. We always advise clients to test a small sample first—this avoids wasting materials and ensures the model meets expectations. Additionally, we’re seeing a trend toward eco-friendly variants (per esempio., water-based silicone, low-VOC resin) to reduce environmental impact, which we actively promote for sustainable replication projects.

4. Domande frequenti: Common Questions About Materials for Mold Replication Models

Q1: Can I use silicone to replicate a model that needs to withstand high temperatures (per esempio., a small engine part)?

SÌ! High-temperature silicone (grade 300°C+) is designed for this scenario. It retains its shape and toughness even at elevated temperatures, making it suitable for replicating heat-exposed parts like small engine components.

Q2: Is gypsum suitable for making detailed figure prototypes?

NO. Gypsum has low replication precision and poor impact resistance—it cannot capture fine details (per esempio., facial features on a figure) and is prone to chipping. For detailed figures, use silicone or epoxy resin instead.

Q3: Do I need safety equipment when using resin for mold replication models?

SÌ. Resin (especially unsaturated resin) releases toxic fumes during mixing and curing. Always work in a well-ventilated area, wear nitrile gloves to protect your hands, and use a face mask to avoid inhaling fumes.