Se ti sei mai chiesto come fanno i prodotti metallici di uso quotidiano, dalle parti della carrozzeria delle automobili agli utensili da cucina, a ottenere le loro forme precise, the answer often lies in stampaggio. Ma cosa significa realmente lo stampaggio nel mondo manifatturiero? Non è solo una semplice azione di “pressione”.; è sofisticato, processo di lavorazione dei metalli altamente efficiente che alimenta le industrie di tutto il mondo. In questa guida, we’ll break down the definition of stamping, its key types, applicazioni del mondo reale, vantaggi, and more—so you can fully understand this critical manufacturing method.

1. The Basic Definition: What Exactly Is Stamping?

Al suo centro, stampaggio (also called the processo di stampaggio) is a metalworking technique that uses two key tools—preme E muore—to shape or cut metal materials. Ecco come funziona:

A press applies controlled external force to flat metal materials (Piace piatti, strips, O fogli) or even 3D metal forms (ad esempio tubes O profiles). The force pushes the material into a custom-designed die (a mold with the desired shape) or between two dies. This force causes the material to either:

- Undergo plastic deformation (change shape without breaking) to match the die’s contour, O

- Separate along a pre-determined line (to cut the material into a specific size).

The end result? A part or product with consistent shape, misurare, and quality—exactly what manufacturers need for mass production.

2. Key Types of Stamping Processes: Separation vs. Modellare

Stamping isn’t a one-size-fits-all process. It’s divided into two main categories based on its goal: separating material or shaping it. Below is a detailed breakdown of each type, with common operations and real examples to make it clear.

| Process Category | Obiettivo primario | Common Operations | Real-World Examples |

| Separation Process | To cut or split material along a fixed contour (no shape change—just size adjustment) | – Soppressione: Cutting a flat metal sheet into a specific shape (per esempio., a circle for a washer).- Punzonatura: Creating holes in a metal part (per esempio., holes in a computer case for screws).- Tosatura: Cutting straight lines in metal (per esempio., trimming the edges of a metal panel for a fridge). | – Making metal washers for machinery.- Punching holes in automotive door handles.- Trimming metal strips for electrical components. |

| Processo di modellatura | To reshape the material into a 3D form (no separation—material stays whole) | – Piegatura: Folding metal at an angle (per esempio., making a 90° bend for a shelf bracket).- Allungamento: Pulling metal over a die to create curved shapes (per esempio., the curved top of a car roof).- Goffratura: Creating raised or recessed designs on metal (per esempio., logos on soda cans or text on metal nameplates). | – Bending metal brackets for furniture.- Stretching aluminum sheets to make pot lids.- Embossing brand logos on stainless steel water bottles. |

3. Where Is Stamping Used? Real-Industry Applications

Stamping is everywhere—you interact with stamped products almost every day. Its ability to produce high-quality, consistent parts at scale makes it a top choice for industries like automotive, home appliances, e altro ancora. Here are the most common applications, with specific examples:

Industria automobilistica

The automotive sector is the largest user of stamping—over 60% of a car’s metal parts are made via stamping (source: Automotive Manufacturing Solutions). Examples include:

- Pannelli di carrozzeria (doors, hoods, fenders).

- Parti interne (dashboard frames, seat brackets).

- Componenti del motore (coppe dell'olio, coperchi delle valvole).

Ad esempio, Toyota uses stamping to produce over 10,000 body parts per day for its Camry model—ensuring every part fits perfectly with zero variation.

Elettrodomestici

Nearly all metal parts in your kitchen or laundry room are stamped. Think:

- Stainless steel inner tubs for washing machines.

- Metal frames for refrigerators or microwaves.

- Utensils like spatulas or mixing bowls (stamped from aluminum or stainless steel).

Samsung, Per esempio, relies on stamping to make 500,000 refrigerator door panels monthly—keeping up with global demand.

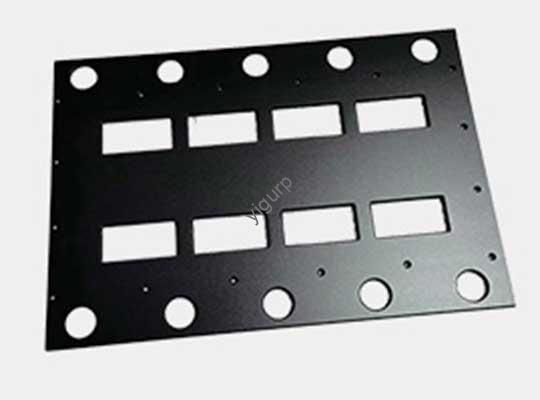

Office Machinery & Elettronica

Stamping is critical for small, precise parts in devices you use at work. Esempi:

- Metal brackets inside printers or copiers.

- Connector pins for laptops or smartphones.

- Heat sinks for computers (stamped from aluminum to dissipate heat).

HP uses stamping to produce 1 million printer brackets per week—ensuring their machines are durable and reliable.

4. Why Manufacturers Love Stamping: Vantaggi principali

What makes stamping so popular? It offers unmatched advantages that help manufacturers save time, soldi, and resources. Here are the top benefits:

- Alta precisione: Stamping dies are engineered to tolerances as tight as ±0.001 inches (0.025 mm). This means every part is identical—critical for products like car parts, where even a tiny mismatch can cause safety issues.

- Smooth Surfaces: Stamped parts have minimal burrs (bordi grezzi) and a clean finish. This eliminates the need for extra polishing or sanding, cutting down on production time.

- Alta produttività: Modern stamping presses can process up to 1,000 parti al minuto. Per esempio, a high-speed press can stamp 500 metal washers in just 30 seconds—far faster than manual methods.

- Conveniente: Once the die is made, the cost per part drops dramatically. Per la produzione di massa (per esempio., 100,000+ parti), stamping is 30-50% cheaper than other methods like casting or machining.

- Wide Material Compatibility: Stamping works with almost all metals, including steel, alluminio, rame, and even titanium. This flexibility makes it useful for industries from aerospace to jewelry.

5. Yigu Technology’s Take on Stamping

Alla tecnologia Yigu, we see stamping as the backbone of modern manufacturing. As a leader in providing precision engineering solutions, we’ve helped 500+ clients—from automotive suppliers to electronics brands—optimize their stamping processes. We believe stamping’s biggest strength is its ability to balance speed, precisione, and cost—something no other metalworking method does as well. Whether our clients need 10,000 small electrical components or 1,000 large automotive panels, we design custom stamping dies and use high-efficiency presses to deliver parts that meet strict quality standards. For manufacturers looking to scale, stamping isn’t just a process—it’s a strategic tool to stay competitive.

Domande frequenti: Common Questions About Stamping

Q1: Can stamping be used for non-metal materials?

While stamping is most commonly used for metals, it can also process certain non-metals like plastic sheets or rubber. Tuttavia, metal stamping remains the most widespread application due to its demand in key industries like automotive and electronics.

Q2: How long does it take to make a stamping die?

The time to make a die depends on its complexity. A simple die (per esempio., for a washer) can take 1-2 settimane, while a complex die (per esempio., for a car fender) may take 4-8 settimane. Alla tecnologia Yigu, we use 3D modeling to speed up die design, riducendo i tempi di consegna 20%.

Q3: Is stamping environmentally friendly?

Yes—stamping generates very little waste. The scrap metal from separation processes (like blanking or punching) is almost 100% riciclabile. Inoltre, modern stamping presses use energy-efficient motors, riducendo le emissioni di carbonio 15-20% compared to older models.