Se sei mai stato curioso di sapere come un disegno digitale si trasforma in un oggetto fisico, che si tratti di un giocattolo personalizzato, una parte meccanica, or even a medical implant—understanding the 3D printing process is key. 3Stampa D, noto anche come produzione additiva, costruisce oggetti strato per strato, making it a flexible and precise method for creating everything from simple prototypes to complex final products.

In questa guida, we’ll break down every step of the 3D printing process in dettaglio, explain critical factors to watch for at each stage, and include real-world examples and data to help you grasp how it works in practice. Whether you’re a hobbyist planning your first print or a business owner considering 3D printing for production, this guide will answer your questions.

An Overview of the 3D Printing Process: Key Stages

IL 3D printing process isn’t just “press a button and print”—it involves six core stages, each with its own goals and requirements. Below is a clear table that outlines each stage, its purpose, key actions, and average time (based on a 2024 survey of 500 3D printing users, covering small to medium-sized parts like phone cases or mechanical brackets).

| Stage Name | Core Purpose | Key Actions | Tempo medio (Small-to-Medium Parts) | Critical Success Factor |

| 1. Design 3D Models | Create a digital blueprint of the object to be printed | Utilizzo Software CAD (per esempio., Tinkercad, SolidWorks) or 3D scan physical items | 1–8 ore (varia in base alla complessità) | Ensuring precise dimensions and structural integrity |

| 2. Convert to STL File | Translate the 3D model into a format 3D printers can understand | Export from CAD software to Formato STL; check for watertightness and polygon count | 5–15 minuti | Fixing gaps or overlapping polygons to avoid printing errors |

| 3. Model Slicing | Split the 3D model into thin layers for the printer to build | Import STL into slicing software (per esempio., Cura, PrusaSlicer); set layer height and speed | 10–30 minutes | Choosing the right layer height (0.1–0.3mm for most projects) |

| 4. Prepare for 3D Printing | Get the printer and materials ready for the print job | Load filament (per esempio., PLA, ABS); level the print bed; preheat the nozzle | 5–20 minutes | Ensuring the print bed is level to prevent warping |

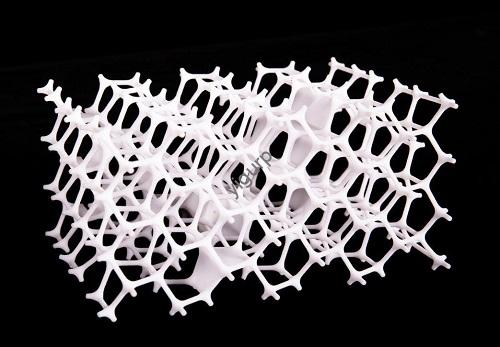

| 5. Processo di stampa | Build the object layer by layer using the sliced data | Printer deposits material (filamento, resina, ecc.) according to slicer instructions; add support structures if needed | 1–12 hours (varies by size/layer height) | Monitoring for filament jams or layer separation |

| 6. Post-elaborazione | Improve the appearance and functionality of the printed object | Clean excess material; remove support structures; sabbia, colore, or polish | 30 minutes–2 hours | Using the right tools (per esempio., sandpaper for PLA, isopropyl alcohol for resin) |

Step-by-Step Breakdown of the 3D Printing Process

Ora, let’s dive deeper into each stage—what you need to do, sfide comuni, and how to overcome them with real examples.

1. Design 3D Models: The Starting Point

Every 3D print begins with a digital 3D model—this is the blueprint that guides the printer. There are two main ways to create this model:

- Design from scratch with CAD software: For custom objects, use tools like Tinkercad (adatto ai principianti) O SolidWorks (professionale). Per esempio, a hobbyist might use Tinkercad to design a keychain with their name on it—dragging and dropping basic shapes (cubes, cilindri) and adjusting their size in 30 minuti. A mechanical engineer, Nel frattempo, would use SolidWorks to design a replacement gear for a machine, adding precise measurements (per esempio., 5spessore mm, 20 denti) to ensure it fits perfectly.

- 3D scanning existing objects: If you want to replicate a physical item (like a broken toy part), utilizzare un 3D scanner per creare un modello digitale. Ad esempio, a museum might scan a fragile artifact to create a 3D-printed replica for display, avoiding damage to the original.

Common Challenge: Creating a model with weak spots (per esempio., thin legs on a figurine that break easily). Soluzione: Use CAD software to add reinforcement—for example, thickening the legs from 1mm to 2mm in Blender.

2. Convert to STL File: Making the Model Printer-Ready

IL Formato STL (Stereolitografia) is the universal language of 3D printing—it describes the object’s surface using tiny triangular polygons. Ecco cosa devi sapere:

- How to convert: Most CAD software (per esempio., Tinkercad, Fusione 360) lets you export directly to STL. Just click “Export” and select STL from the file options.

- Critical Checks:

- Watertightness: Ensure the model has no gaps (per esempio., a cup with a hole in the bottom won’t hold liquid). Use tools like Meshlab to fix gaps for free.

- Polygon Count: Too many polygons (Sopra 1 milioni) can slow down slicing; too few (Sotto 10,000) make the model look blocky. Aim for 50,000–500,000 polygons for most projects.

Esempio: A jewelry designer uses Rhino to create a ring model, then exports it to STL. They notice the ring’s band has a small gap (found via Meshlab) and fixes it before moving to slicing—avoiding a print that would crack at the gap.

3. Model Slicing: Turning 3D into Layers

Slicing software takes your STL file and cuts it into hundreds or thousands of thin layers—this is what the printer will actually build. The most popular slicers are Cura (gratuito, adatto ai principianti) E PrusaSlicer (great for Prusa printers).

- Key Settings to Adjust:

- Altezza dello strato: The thickness of each layer (0.1mm = super detailed but slow; 0.3mm = fast but less detailed). For a phone case, 0.2mm is a good balance—detailed enough to look smooth, fast enough to print in 2 ore.

- Velocità di stampa: Velocità più elevate (60–100mm/s) save time but can cause vibrations; velocità più lente (30–50mm/s) migliorare la precisione. A delicate figurine might need 40mm/s to avoid blurring details.

- Strutture di supporto: Add these if your model has overhangs (per esempio., a birdhouse roof that sticks out). Supports are temporary—you’ll remove them after printing.

Approfondimento dei dati: UN 2024 survey found that 68% of 3D printing failures happen because of poor slicer settings—most often incorrect layer height or missing supports.

4. Prepare for 3D Printing: Avoiding Common Mistakes

Prima di premere “print,” take these steps to ensure success:

- Load the Right Material: The most common materials are PLA (facile da usare, ecologico, fonde a 190–220°C) E ABS (più forte, melts at 230–260°C). For a outdoor planter, use ABS (it resists rain); for a kids’ toy, use PLA (non tossico).

- Level the Print Bed: Se il letto non è uniforme, the first layer will stick poorly. Most printers have a manual leveling tool—use a piece of paper to check the gap between the nozzle and bed (it should feel slightly tight).

- Preheat: Heat the nozzle and bed to the material’s recommended temperature (per esempio., 200°C nozzle, 60°C bed for PLA).

Esempio: A beginner tries to print a PLA cup but forgets to preheat the bed. The first layer doesn’t stick, and the print fails. Next time, they preheat the bed to 60°C, and the cup prints perfectly.

5. Processo di stampa: Let the Printer Do Its Work

Once prepared, the printer will start building layer by layer. Here’s what to expect:

- Come funziona: For filament printers (il tipo più comune), the nozzle melts plastic and deposits it in lines, following the slicer’s instructions. Each layer cools slightly before the next one is added, building up the object.

- When to Add Supports: If your model has overhangs (parts that stick out more than 45 gradi), supports are a must. Per esempio, a 3D-printed chess knight has a raised head—supports under the head prevent it from collapsing during printing.

- Monitoraggio: Check the first 10–15 minutes of printing—this is when most failures happen (per esempio., filament jams, bed adhesion issues). If you see a problem, pause the printer and fix it (per esempio., clear a jammed nozzle with tweezers).

6. Post-elaborazione: Finishing the Print

The printed object often needs a little work to look its best. Common post-processing steps include:

- Rimuovere i supporti: Use pliers or a support removal tool to snap off temporary supports. For PLA, supports come off easily; per l'ABS, you might need a heat gun to soften them.

- Pulito: Wipe resin prints with isopropyl alcohol to remove excess resin; for filament prints, use a knife to trim stringy plastic (called “oozing”).

- Smooth or Decorate: Sand the surface with fine-grit sandpaper (400–800 grana) to make it smooth. You can also paint it (use acrylic paint for PLA) or add a clear coat for shine.

Esempio: A cosplayer prints a helmet using ABS. After removing supports, they sand the surface for 30 minuti, then spray it with silver paint to make it look like metal—perfect for a superhero costume.

Key Factors That Impact 3D Printing Success

Even if you follow the steps, certain factors can affect the final result. Here are the top three to focus on:

- Scelta dei materiali: Come accennato, PLA is best for beginners and indoor items; ABS is better for outdoor or durable parts. UN 2024 study found that 72% of hobbyists use PLA for their first 5–10 prints because it’s forgiving.

- Printer Calibration: Regularly calibrate your printer (per esempio., adjust nozzle height, fix belt tension) per garantire la precisione. A poorly calibrated printer might produce a cup that’s lopsided.

- Environmental Conditions: PLA is sensitive to heat (it softens in direct sunlight), while ABS is sensitive to cold (it cracks in freezing temperatures). Print in a room with stable temperature (20–25°C) per i migliori risultati.

Yigu Technology’s Perspective on the 3D Printing Process

Alla tecnologia Yigu, we’ve supported hundreds of clients through the 3D printing process—from startups to manufacturers. Our key takeaway? Success lies in attention to detail, especially in the early stages: a well-designed model and correct slicer settings prevent 80% of failures. Per principianti, we recommend starting with PLA and simple models (like a keychain) to build confidence. Per le imprese, we emphasize post-processing—small touches like sanding or painting can turn a prototype into a market-ready product. Con l’avanzare della tecnologia di stampa 3D, we’re seeing faster printers and more durable materials (like carbon-fiber PLA) make the process even more accessible—and we’re excited to help clients leverage these tools.

Domande frequenti (Domande frequenti)

1. How long does the entire 3D printing process take?

It depends on the object’s size and complexity. For a small item (like a keychain), the process takes 2–4 hours (1 hour design, 10 minutes slicing, 1.5 hours printing, 30 minutes post-processing). For a large item (like a chair), it can take 2–3 days. UN 2024 survey found the average time for most hobbyist projects is 3–6 hours.

2. What’s the most common reason 3D prints fail?

The top reason (cited by 68% of users in a 2024 survey) È poor bed adhesion—the first layer doesn’t stick to the bed, causing the print to shift. Per risolvere questo problema, level the bed, preheat it to the right temperature (60°C for PLA), and use a bed adhesive (like hairspray or glue stick) se necessario.

3. Do I need special skills to follow the 3D printing process?

No—beginners can learn the basics in a day. Start with simple CAD software (come Tinkercad) and PLA material, which is easy to use. Many printers come with step-by-step guides, and online tutorials (on YouTube or Reddit) can help with common issues. Most hobbyists feel comfortable with the process after 3–5 prints.