Se stai cercando “Vacuum Casting Germany,"probabilmente sei uno sviluppatore di prodotti, ingegnere, o produttore che necessita di alta precisione, parti a basso volume, sia per la prototipazione, pre-produzione, o produzione in piccoli lotti. La Germania è un leader globale in questa tecnologia, grazie ai suoi rigorosi standard di qualità, macchinari avanzati, e competenza nella scienza dei materiali. Insomma, colata sotto vuoto in Germania offre coerente, parti dettagliate con eccellenti finiture superficiali, rendendolo ideale per settori come quello automobilistico, medico, e aerospaziale. Questa guida analizzerà tutto ciò che devi sapere, da come funziona il processo alla scelta del partner giusto e alla comprensione delle ultime tendenze.

Che cos'è la fusione sottovuoto, e perché la Germania eccelle in questo?

Colata sotto vuoto (chiamata anche replicazione del vuoto) è un processo di produzione a basso volume che utilizza uno stampo in silicone per produrre parti in plastica o resina. A differenza dello stampaggio ad iniezione, che richiede costose attrezzature metalliche, la fusione sotto vuoto utilizza stampi in silicone flessibili, rendendola conveniente per le serie di 10 A 1000 parti. Il processo funziona posizionando un modello master (spesso stampati in 3D) in un telaio dello stampo, versandovi attorno del silicone liquido, e polimerizzare il silicone per creare uno stampo. Una volta pronto lo stampo, la resina liquida viene versata al suo interno sotto pressione (per eliminare le bolle), guarito, e poi rimosse, ottenendo parti che corrispondono ai dettagli del master.

La Germania si distingue nella colata sotto vuoto per tre ragioni principali:

- Standard di qualità: I produttori tedeschi aderiscono alla norma DIN (Istituto tedesco per la standardizzazione) e gli standard ISO, garantire che le parti soddisfino tolleranze rigorose (spesso fino a ±0,1 mm per componenti di piccole dimensioni).

- Innovazione dei materiali: I fornitori tedeschi offrono una vasta gamma di resine ad alte prestazioni, incluso ritardante di fiamma, di livello medico, e opzioni resistenti al calore, fondamentali per settori come quello automobilistico e sanitario.

- Competenza tecnica: Gli ingegneri tedeschi hanno decenni di esperienza nell'ottimizzazione del processo di fusione sottovuoto, dalla progettazione dello stampo alla post-lavorazione, riducendo i difetti e migliorando la consistenza.

Esempio del mondo reale: Serve una startup automobilistica con sede a Berlino 500 componenti del dashboard prototipo per i test. Utilizzo della fusione sottovuoto da un fornitore bavarese, hanno ricevuto parti con finitura opaca (corrispondente alle specifiche di produzione finali) nel giusto 10 giorni—a 70% il costo degli utensili per lo stampaggio a iniezione.

Principali applicazioni della fusione sotto vuoto nelle principali industrie tedesche

Il panorama industriale tedesco fa molto affidamento sulla fusione sotto vuoto per la sua flessibilità e precisione. Di seguito sono riportati i settori in cui è maggiormente utilizzato, con casi d'uso specifici:

Automotive e Mobilità

L'industria automobilistica tedesca (sede della BMW, Mercedes-Benz, e Volkswagen) utilizza la fusione sotto vuoto per la prototipazione e parti a basso volume come:

- Componenti interni (per esempio., maniglie delle porte, prototipi di console centrale)

- Pezzi di rivestimento esterni (per esempio., tappi paraurti, alloggiamenti degli specchietti)

- Parti sotto il cofano (per esempio., alloggiamenti dei sensori, organizzatori di cavi)

Punto dati: Lo afferma l'Associazione tedesca dell'industria automobilistica (VDA), 65% dei prototipi automobilistici in Germania vengono prodotti utilizzando la fusione sotto vuoto o la stampa 3D, con la fusione sotto vuoto preferita per le parti che richiedono un'elevata qualità superficiale.

Tecnologia medica

La Germania è leader nella produzione di dispositivi medici (aziende come Siemens Healthineers e B. Braun), e la fusione sotto vuoto è l'ideale qui perché:

- Utilizza resine biocompatibili (conforme all'ISO 10993 e gli standard FDA)

- Produce parti con superfici lisce (fondamentale per dispositivi come strumenti chirurgici o apparecchiature diagnostiche)

- Consente iterazioni rapide per il test del prototipo

Caso di studio: Cercavamo un'azienda di dispositivi medici con sede ad Amburgo 200 prototipi di una nuova penna per la somministrazione di insulina. Un fornitore tedesco di colata sottovuoto ha utilizzato una resina di policarbonato di grado medico, fornendo parti che hanno superato i test di biocompatibilità e che erano pronte per le sperimentazioni cliniche 2 settimane.

Aerospaziale e Difesa

Per applicazioni aerospaziali (per esempio., parti per droni, satelliti, o interni di aerei), offerte di colata sottovuoto in Germania:

- Resistenza alle temperature estreme (utilizzando resine ad alte prestazioni come PEEK o epossidiche)

- Parti leggere con elevati rapporti resistenza/peso

- Conformità agli standard aerospaziali (per esempio., IN 9100)

Elettronica di consumo

Marchi come Siemens e Bosch utilizzano la fusione sotto vuoto per la produzione in piccoli lotti di parti elettroniche, ad esempio:

- Contenitori personalizzati per dispositivi IoT

- Prototipi per smartphone o wearable

- Connettori per cavi con tolleranze strette

Come funziona la fusione sotto vuoto negli stabilimenti tedeschi: Un'analisi dettagliata

I produttori tedeschi seguono uno standard, processo orientato ai dettagli per garantire risultati coerenti. Di seguito è riportata una panoramica passo passo, con approfondimenti su come le pratiche tedesche differiscono dagli standard globali:

- Preparazione del modello principale

Il modello principale (il “modello” per la parte finale) viene solitamente stampato in 3D utilizzando SLA (Stereolitografia) o SLS (Sinterizzazione laser selettiva) tecnologia. Le strutture tedesche utilizzano spesso stampanti 3D ad alta precisione (con altezze dello strato fino a 0,025 mm) per garantire che il master non abbia difetti. Se la parte richiede una finitura specifica (per esempio., lucido, strutturato), il master viene post-elaborato (levigato, dipinto) abbinare.

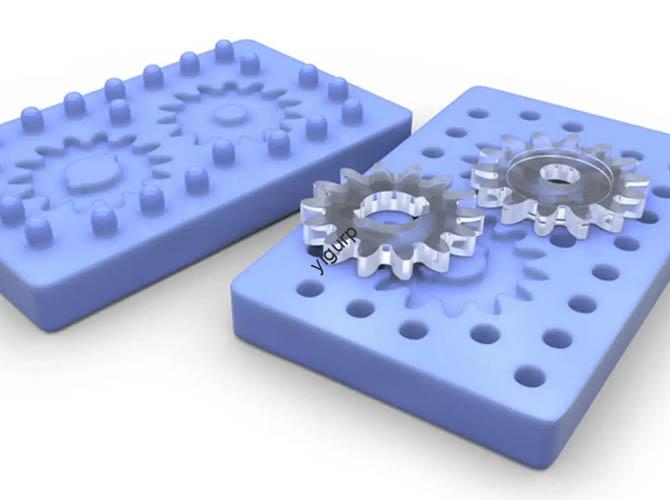

- Creazione Stampi in Silicone

Il master viene posizionato in una cornice di stampo, e silicone liquido (spesso una gomma siliconica in due parti) viene versato attorno ad esso. I produttori tedeschi utilizzano camere a vuoto durante questa fase per rimuovere le bolle d'aria dal silicone, garantendo che lo stampo catturi ogni dettaglio del modello. Il silicone viene poi polimerizzato in un forno (tipicamente a 60–80°C per 2–4 ore). Una volta guarito, lo stampo viene aperto per rimuovere il maestro, lasciando una cavità che corrisponde alla forma della parte. La maggior parte degli stampi in silicone può produrre 20-50 parti prima di dover essere sostituite (I siliconi tedeschi spesso durano più a lungo dei siliconi standard, fino a 100 parti per gradi di alta qualità).

- Colata e polimerizzazione della resina

La resina liquida viene miscelata (con coloranti o additivi se necessario) e versato nello stampo in silicone. Lo stampo viene quindi posizionato in una camera a vuoto per eliminare le bolle d'aria: questo è fondamentale per le parti con geometrie complesse (per esempio., pareti sottili, piccoli fori). Le strutture tedesche utilizzano controllori digitali del vuoto per mantenere una pressione precisa (Generalmente -0.95 sbarra) durante tutto il processo. Lo stampo viene quindi stagionato (sia con il calore che con la luce UV, a seconda della resina) per 1–4 ore.

- Post-elaborazione

Dopo la polimerizzazione, la parte viene rimossa dallo stampo. I produttori tedeschi eseguono quindi fasi di post-elaborazione come il taglio della resina in eccesso, levigatura, pittura, o aggiungendo inserti (per esempio., fili metallici). Alcune strutture offrono anche trattamenti aggiuntivi, come la placcatura (per finiture simil-metallo) o ricottura (per migliorare la resistenza della parte).

Differenza chiave: Le strutture tedesche utilizzano spesso sistemi automatizzati per la miscelazione e il versamento della resina, riducendo l'errore umano e garantendo rapporti di resina coerenti. Conducono anche 100% ispezioni visive delle parti (utilizzando fotocamere ad alto ingrandimento) per verificare la presenza di difetti, cosa che non tutti i fornitori globali fanno.

Scegliere il giusto partner per la fusione sotto vuoto in Germania: Cosa cercare

Con così tanti fornitori in Germania, selezionare il partner giusto può essere travolgente. Di seguito è riportato un elenco di fattori da considerare, sulla base delle migliori pratiche del settore:

| Fattore | Cosa cercare | Perché è importante |

| Certificazioni di qualità | LA TUA EN ISO 9001 (gestione della qualità), ISO 13485 (dispositivi medici), IN 9100 (aerospaziale) | Le certificazioni garantiscono che il fornitore segua rigorosi processi di controllo qualità, fondamentali per i settori regolamentati. |

| Gamma di materiali | Accesso a resine ad alte prestazioni (per esempio., di livello medico, ritardante di fiamma, resistente al calore) e la capacità di reperire materiali personalizzati | Garantisce che la parte soddisfi i requisiti della tua applicazione (per esempio., biocompatibilità per parti medicali). |

| Tempi di consegna | Capacità di consegnare le parti in 5-10 giorni lavorativi (standard per i fornitori tedeschi) | I tempi di consegna rapidi sono fondamentali per la prototipazione o i test di pre-produzione. |

| Supporto alla progettazione | Ingegneri interni che possono rivedere la producibilità del tuo modello 3D (DFM) | Le revisioni DFM aiutano a evitare difetti di progettazione che potrebbero rovinare lo stampo o la parte. |

| Capacità del volume | Esperienza con tirature di 10–1000 pezzi (il punto debole per la fusione sotto vuoto) | Alcuni fornitori sono specializzati in piccole tirature (10–50 parti), mentre altri gestiscono lotti più grandi (500–1000 parti). |

| Recensioni dei clienti | Feedback positivo dai clienti del tuo settore (per esempio., automobilistico, medico) | Le recensioni indicano affidabilità e qualità: cerca fornitori con a 4.5+ valutazione in stelle su piattaforme come Trustpilot. |

Mancia: Richiedi un campione prima di effettuare un ordine di grandi dimensioni. La maggior parte dei fornitori tedeschi produrrà un unico campione (per una piccola tassa) per dimostrare la loro qualità.

Costo della fusione sotto vuoto in Germania: Cosa aspettarsi

La fusione sotto vuoto in Germania è più costosa che in paesi come la Cina, ma il costo più elevato riflette una migliore qualità, tempi di consegna più rapidi, e standard più severi. Di seguito è riportata una ripartizione dei costi tipici (a partire da 2025):

- Modello principale: €150–€500 (a seconda delle dimensioni e della complessità; 3I modelli SLA stampati in D sono più convenienti dei modelli master lavorati a CNC).

- Stampo in silicone: € 300–€ 1.200 (il costo varia in base alle dimensioni dello stampo e al grado di silicone; il silicone per uso medico è più costoso).

- Costo per parte: €5–€50 (per pezzi medio-piccoli; parti più grandi o più complesse possono costare fino a € 100 ciascuna).

Esempio: Per 100 piccole parti di prototipi automobilistici (per esempio., un alloggiamento del sensore da 5 cm x 3 cm), i costi totali sarebbero:

- Modello maestro: €200

- Stampo in silicone: €400

- Costo per parte: €8x 100 = 800€

- Totale: € 1.400

Confrontalo con lo stampaggio a iniezione, che costerebbe € 5.000–€ 10.000 per utensili in metallo (più € 1–€ 2 per azione)—la fusione sotto vuoto è molto più conveniente per volumi bassi.

Suggerimento per risparmiare sui costi: Se hai bisogno di più parti simili, chiedere al fornitore di progettare uno “stampo familiare” (un unico stampo con più cavità). Ciò riduce i costi dello stampo e i costi per pezzo.

Ultime tendenze nella tecnologia della colata sottovuoto in Germania

I produttori tedeschi innovano costantemente per migliorare la velocità della colata sottovuoto, qualità, e sostenibilità. Ecco le principali tendenze da tenere d’occhio:

1. Materiali sostenibili

Mentre la Germania spinge per la neutralità del carbonio (attraverso la sua transizione energetica, o “transizione energetica”), i fornitori stanno passando a resine ecologiche. Questi includono:

- Resine a base biologica (realizzato con materiali di origine vegetale come l'amido di mais)

- Resine riciclate (utilizzando rifiuti di plastica post-consumo)

- Basso contenuto di COV (composto organico volatile) resine (ridurre l’impatto ambientale e migliorare la sicurezza sul lavoro)

Punto dati: Lo dice la Federazione tedesca dell'industria chimica (VCI), l’uso di resine sostenibili nella colata sottovuoto è aumentato del 35% Da 2022.

2. Automazione e Digitalizzazione

Gli stabilimenti tedeschi adottano l’industria 4.0 tecnologie per semplificare il processo:

- Monitoraggio digitale degli stampi: I sensori negli stampi in silicone monitorano la temperatura e la pressione, avvisare gli operatori dei problemi (per esempio., degrado della muffa) prima che incidano sulle parti.

- DFM basato sull'intelligenza artificiale: Gli strumenti di intelligenza artificiale analizzano i modelli 3D per prevedere potenziali problemi di produzione (per esempio., pareti sottili che potrebbero rompersi) e suggerire modifiche al design.

- Post-elaborazione automatizzata: I robot gestiscono attività come la rifinitura e la levigatura, ridurre i costi del lavoro e migliorare la coerenza.

3. Produzione ibrida

Alcuni fornitori tedeschi stanno combinando la fusione sottovuoto con la stampa 3D per creare “parti ibride”. Per esempio:

- Un nucleo stampato in 3D (per forza) è incapsulato in uno strato esterno di resina colata sotto vuoto (per la finitura superficiale).

- Questo approccio è ideale per le parti che necessitano di elevata resistenza (per esempio., componenti strutturali) e un aspetto liscio (per esempio., parti rivolte al consumatore).

La prospettiva di Yigu Technology sulla fusione sotto vuoto in Germania

Yigu Technology riconosce che la Germania costituisce il punto di riferimento globale per l'eccellenza della fusione sotto vuoto, in particolare nel controllo qualità e nell’innovazione dei materiali. L’attenzione del Paese è rivolta al rispetto di standard rigorosi (come DIN e ISO) è in linea con il nostro impegno a fornire prodotti affidabili, parti pronte per l'applicazione per clienti in tutto il mondo.

Ciò che risalta maggiormente nella fusione sottovuoto tedesca è il suo equilibrio tra precisione e flessibilità, fondamentale per i frenetici cicli di sviluppo prodotto di oggi.. Mentre i costi sono più alti che in alcune regioni, il ridotto rischio di difetti, tempi di consegna più rapidi, e accesso a materiali specializzati (come le resine per uso medico) spesso giustificano l’investimento, soprattutto per le industrie in cui la qualità non può essere compromessa.

Alla tecnologia Yigu, collaboriamo spesso con partner tedeschi per sfruttare la loro esperienza per progetti complessi, garantire che i nostri clienti traggano vantaggio dalle migliori capacità produttive globali.

Domande frequenti sulla fusione sottovuoto in Germania

1. Quanto tempo impiega la fusione sotto vuoto in Germania?

La maggior parte dei fornitori consegna le parti in 5-10 giorni lavorativi. Ciò include la preparazione del modello principale (1–2 giorni), realizzazione stampi in silicone (2–3 giorni), colata e polimerizzazione della resina (1–2 giorni), e post-elaborazione (1 giorno).

2. Quali materiali vengono utilizzati nella fusione sotto vuoto tedesca?

I materiali comuni includono resine poliuretaniche (il più popolare, per uso generale), resine epossidiche (per alta resistenza), resine acriliche (per la trasparenza), e resine speciali (per esempio., di livello medico, ritardante di fiamma, o resistente al calore).

3. La fusione sotto vuoto in Germania è adatta per grandi cicli di produzione?

No, la fusione sottovuoto è ideale per tirature medio-basse (10–1000 parti). Per tirature di 1000+ parti, lo stampaggio ad iniezione è più conveniente (una volta ammortizzati i costi delle attrezzature).

4. La fusione sotto vuoto in Germania può produrre parti con tolleranze strette?

Sì, i fornitori tedeschi possono raggiungere tolleranze di ±0,1 mm per le parti di piccole dimensioni (fino a 10 cm) e ±0,2 mm per parti più grandi (10–30 cm). Ciò è dovuto ai modelli master ad alta precisione e al rigoroso controllo del processo.

5. I fornitori tedeschi di colata sotto vuoto offrono supporto nella progettazione?

La maggior parte lo fa: molti hanno ingegneri interni che forniscono DFM (Progettazione per la producibilità) revisioni per garantire che il tuo modello 3D sia ottimizzato per la fusione sotto vuoto (per esempio., evitando sottosquadri, garantire uno spessore adeguato delle pareti).