3La stampa D ha rivoluzionato la produzione offrendo infinite possibilità nella creazione di forme complesse e parti funzionali. Un fattore chiave che rende possibile questa versatilità è l’ampia gamma di materiali di stampa 3D oggi disponibili. Ogni materiale ha proprietà uniche che lo rendono adatto a tecnologie e applicazioni specifiche. Let’s dive into the most common types of 3D printing materials and discover how they’re used.

Ingegneria delle materie plastiche: The Workhorses of 3D Printing

Engineering plastics are among the most widely used 3D printing materials, especially in consumer and hobbyist 3D printers. They balance affordability, ease of use, e funzionalità, making them perfect for a variety of projects.

- ABS (Acrilonitrile-Butadiene-Stirene) is a popular choice for FDM (Modellazione della deposizione fusa) printers. It’s known for its strength and impact resistance, which means parts printed with ABS can withstand some rough handling. This makes it great for functional prototypes, giocattoli, and even mechanical parts. Tuttavia, ABS can be a bit tricky to print with as it may warp if the printer’s bed isn’t heated properly (usually around 100°C).

- PLA (Acido Polilattico) is another staple in FDM printing and is often recommended for beginners. Made from renewable resources like corn starch or sugarcane, PLA is more environmentally friendly than ABS. It’s easier to print with since it requires lower temperatures (around 190 – 210°C for the nozzle) and is less likely to warp. PLA produces smooth finishes, making it ideal for decorative items, prototipi, and educational models. The downside is that it’s not as strong as ABS and can soften in high temperatures (above 60°C).

Photosensitive Resins: Precision and Detail Champions

Photosensitive resins are liquid materials that cure quickly when exposed to UV light, making them perfect for technologies like SLA (Stereolitografia) e DLP (Elaborazione digitale della luce). These materials are all about precision and surface quality.

- What sets photosensitive resins apart is their ability to produce models with extremely fine details and smooth surfaces. They can capture tiny features as small as 0.1mm, which is why they’re favored for creating jewelry, modelli dentali, and detailed figurines.

- There are different types of photosensitive resins available, ciascuno adattato alle esigenze specifiche. Some offer high flexibility, while others are designed for high temperature resistance or biocompatibility (important for medical applications). Dopo la stampa, resin models need to be washed in isopropyl alcohol to remove uncured resin and then cured further under UV light to maximize their strength.

Rubber Materials: Flessibilità ed elasticità

If you need 3D printed parts that can bend, stirata, or bounce, rubber materials are the way to go. These materials mimic the properties of natural rubber, offering flexibility and elasticity.

- Gomma – like 3D printing materials are often used to create items such as phone cases, guarnizioni, sigilli, and even shoe soles. They can absorb shocks, making them ideal for parts that need to withstand impacts or repeated bending.

- Most rubber materials are used with FDM or resin printers. For FDM, they come in filament form, while for resin printers, they’re liquid resins with flexible properties. When printed, these materials have a Shore hardness ranging from 30A to 90A, allowing you to choose the right level of flexibility for your project.

Materiali metallici: Strength and Durability for Industrial Use

For industrial applications that require strong, parti durevoli, metal 3D printing materials are the top choice. They’re used in technologies like SLM (Fusione laser selettiva) e SLS (Sinterizzazione laser selettiva), which can melt and fuse metal particles into solid parts.

| Metal Material | Proprietà chiave | Applicazioni comuni |

| Leghe di titanio | Alta resistenza – A – rapporto peso, resistenza alla corrosione | Componenti aerospaziali, impianti medici |

| Acciaio inossidabile | Forte, corrosione – resistente, durevole | Strumenti industriali, parti automobilistiche, gioielli |

| Leghe di alluminio | Leggero, buona conduttività termica | Dissipatori di calore, parti aerospaziali, prototipi |

| Rame | Excellent electrical and thermal conductivity | Componenti elettrici, scambiatori di calore |

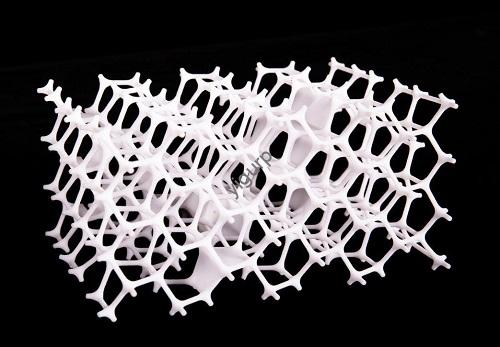

- Metal 3D printing materials allow the creation of complex geometries that would be impossible with traditional manufacturing methods. Per esempio, titanium alloy medical implants can be designed with porous structures that help bone grow into the implant, improving integration with the body.

- While metal materials offer exceptional performance, they do require specialized printers and are more expensive than plastic materials, making them best suited for high – value applications.

Materiali ceramici: Heat Resistance and Precision

Ceramic 3D printing materials are perfect for creating parts that need to withstand high temperatures and have excellent mechanical properties. They’re used in a variety of advanced applications.

- Ceramics can handle extreme heat (often above 1000°C), making them ideal for parts like engine components, kiln fixtures, e alto – temperature sensors. They’re also biocompatible, which means they’re used in dental implants and other medical devices that need to interact safely with the human body.

- 3D printed ceramic parts are known for their precision and smooth surfaces. Artists also use ceramic materials to create intricate sculptures and art pieces that combine functionality with aesthetics. The printing process for ceramics often involves printing a ceramic – filled resin, which is then fired in a kiln to remove the binder and sinter the ceramic particles into a solid part.

Materiali compositi: Combining Strengths for Enhanced Performance

Composite 3D printing materials are made by combining two or more materials to create a new material with improved properties. They’re designed to offer the best of both worlds.

- Carbon fiber reinforced plastics are a popular type of composite material. By adding carbon fiber to plastic, the resulting material is much stronger and stiffer than pure plastic while remaining lightweight. These composites are used to print structural parts for drones, racing cars, and aerospace prototypes where strength and weight are critical factors.

- Other composite materials include glass fiber reinforced plastics and metal matrix composites. These materials allow engineers to tailor the properties of the printed part to specific needs, such as increasing impact resistance or improving thermal conductivity.

Biomaterials: Advancing Medicine and Tissue Engineering

Biomaterials are a specialized category of 3D printing materials used in bioprinting, a cutting – edge field that aims to print living tissues and organs. These materials are designed to be compatible with living cells.

- Cellular bioraw materials, often called bioinks, contain living cells suspended in a gel – like substance. When printed, these bioinks can form structures that mimic the extracellular matrix, allowing cells to grow and differentiate into specific tissues.

- Biomaterials are used in research to create 3D models of organs for drug testing, reducing the need for animal testing. In the future, they may be used to print replacement tissues or even whole organs for transplantation, revolutionizing medicine.

Food Materials: Edible 3D Printing Creations

3D printing isn’t just for industrial or medical parts – it can also be used to create delicious and visually stunning food. Food materials for 3D printing are becoming increasingly popular in restaurants and food production.

- Common food materials include granulated sugar, cioccolato, dough, and pureed fruits and vegetables. These materials are loaded into food – safe 3D printers, which extrude them layer by layer to create intricate shapes and designs.

- Food 3D printing allows chefs to create unique garnishes, costume – shaped chocolates, and even personalized cakes with detailed patterns that would be hard to achieve by hand. It’s also used in food production to create uniform portions and reduce waste.

Plaster Materials: Colorful and Versatile for Art and Prototyping

Plaster materials offer a unique set of properties that make them useful for certain 3D printing applications, especially in art and prototyping.

- Colored plaster materials can be used to print vibrant, full – color models and sculptures. They’re easy to post – process – you can sand them to create smooth surfaces or paint them to enhance details. This makes them a favorite among artists and designers.

- Plaster 3D printing is often used to create molds for casting other materials like metal or resin. The plaster mold can be printed with intricate details, allowing for the production of complex parts through casting.

Artificial Bone Meal: 3D Printing in Orthopedic Medicine

Artificial bone meal is a specialized material used in the medical field to create orthopedic implant models and even custom bone grafts.

- This material is designed to mimic the properties of natural bone, making it biocompatible and able to integrate with the patient’s existing bone tissue. 3D printing with artificial bone meal allows surgeons to create implants that perfectly match the patient’s anatomy, improving the success rate of orthopedic surgeries.

- Before surgery, doctors can also print models of the patient’s bone structure using artificial bone meal to plan the procedure, ensuring greater precision during the actual operation.

Yigu Technology’s View

The diversity of 3D printing materials drives its wide applications. From engineering plastics for daily prototypes to metals and biomaterials for high – end industries, each material has unique value. Alla tecnologia Yigu, we emphasize matching materials to technologies and needs, as choosing the right material ensures print quality and design realization, pushing 3D printing innovation forward.

Domande frequenti

- What are the most common 3D printing materials for beginners?

PLA is the most common for beginners. It’s easy to print with, has low warping issues, and is affordable, making it ideal for those new to 3D printing using FDM technology.

- Which 3D printing materials are suitable for high – temperature applications?

Ceramic materials are excellent for high – temperature applications as they can withstand temperatures above 1000°C, making them suitable for engine components and high – temp sensors.

- Are there environmentally friendly 3D printing materials?

SÌ, PLA is an environmentally friendly option. It’s made from renewable resources like corn starch and is biodegradable under certain conditions, unlike petroleum – based plastics.