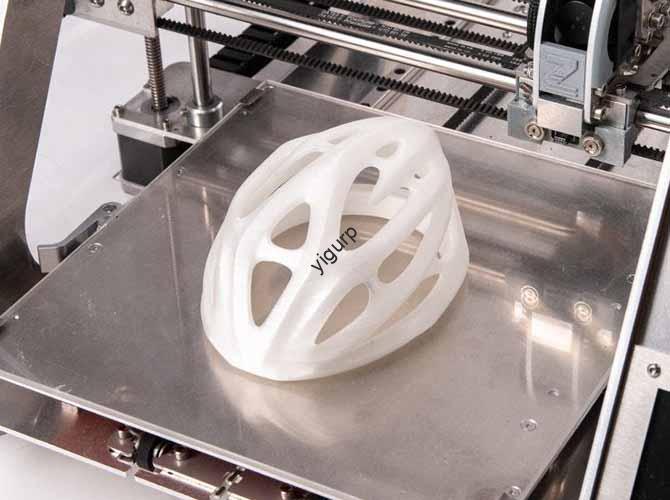

Our PC 3D Printing Services

Elevate your manufacturing game with PC 3D Printing—the perfect fusion of durable Polycarbonate and advanced additive manufacturing technologies. From high-strength automotive components to intricate consumer electronics parts, we deliver custom solutions that blend complex geometries, rapid turnaround, and cost-effectiveness. Whether you need prototyping or end-use parts, our precision-driven process turns your designs into reality, faster and more reliably than ever.

What Is PC 3D Printing?

PC 3D Printing leverages Polycarbonate (a robust, heat-resistant thermoplastic) and 3D Printing technologies to build parts layer by layer—a core principle of additive manufacturing. Unlike traditional subtractive methods, this approach uses techniques like Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS) to create objects from digital designs, enabling flexibility that’s hard to match.

Key technologies powering PC 3D Printing:

| Technology | Core Mechanism | Ideal PC Applications |

| Fused Deposition Modeling (FDM) | Thermoplastic Extrusion of PC filament | Large-format parts (e.g., automotive housings) |

| Stereolithography (SLA) | Photopolymerization of PC-blend resins | High-detail prototypes (e.g., consumer electronics components) |

| Selective Laser Sintering (SLS) | Sintering of PC powder | Durable end-use parts (e.g., industrial gears) |

At its heart, PC 3D Printing enables digital prototyping and layer-by-layer fabrication, turning abstract ideas into tangible, functional parts in days—not weeks.

Our Capabilities: Bringing Your Visions to Life

At Yigu Technology, we’ve honed a suite of capabilities to meet the diverse needs of industries ranging from aerospace to consumer goods. Our expertise covers every stage of the PC 3D Printing journey:

- Custom 3D Printing: We tailor parts to your exact specs, whether you need unique complex geometries for robotics or lightweight structures for sports equipment.

- Precision Manufacturing: Our machines deliver high-resolution printing (down to 50μm layer thickness) and tight tolerances, ensuring parts fit seamlessly into your systems.

- Large-Format Printing: We handle PC parts up to 1000mm × 800mm × 500mm—ideal for architectural models or industrial equipment enclosures.

- Rapid Prototyping: Cut lead times from 4–6 weeks to 3–5 days, letting you test and refine designs faster than ever.

- Post-Processing Services: From sanding to coating, we refine parts to meet your aesthetic and functional needs (e.g., UV curing for enhanced durability).

Table: Our Capabilities vs. Industry Benchmarks

| Capability | Yigu Technology Performance | Industry Average |

| Max Print Size | 1000×800×500mm | 600×600×600mm |

| Prototyping Lead Time | 3–5 days | 7–10 days |

| Print Resolution | 50–100μm | 100–200μm |

| Multi-Material Support | Up to 3 materials (e.g., PC + carbon fiber) | 1–2 materials |

Process: From Design to Finished PC Part

Our PC 3D Printing process is a structured, quality-focused workflow that ensures consistency and reliability:

- Design Phase: Collaborate with our team to finalize your CAD model, optimizing it for PC’s properties (e.g., accounting for minimal warping).

- CAD Modeling & STL Conversion: We convert your design into an STL file—compatible with all major slicing software (e.g., Cura, Simplify3D).

- Print Preparation: The slicer breaks the model into layers (0.05–0.3mm) and sets parameters (e.g., temperature for PC extrusion: 250–300°C).

- Layer Deposition: Using FDM (most common for PC), the printer extrudes molten PC filament layer by layer, or for resins, SLA uses UV light for curing process.

- Support Structure Removal: For overhanging parts, we carefully remove soluble or breakaway supports without damaging the PC part.

- Post-Curing (if applicable): SLA-printed PC parts undergo UV post-curing to boost strength and stability.

Quality Control: Every part is inspected with laser scanners to check dimensional accuracy and ensure it meets your specs.

Materials: Choosing the Right PC for Your Project

Polycarbonate (PC) is a versatile thermoplastic, but we offer specialized variants to match your application’s demands. Here’s how our materials stack up:

| Material Type | Key Properties | Ideal Applications |

| Standard PC Filament | High impact resistance (65kJ/m²), heat resistance (120°C HDT) | Consumer electronics housings, toys |

| Carbon Fiber Reinforced PC | 30% higher strength than standard PC, low weight | Aerospace brackets, robotics parts |

| Glass Fiber Reinforced PC | Improved stiffness, chemical resistance | Automotive underhood components |

| PC-ABS Blend | Balanced impact strength and flexibility | Industrial equipment enclosures |

| PC Photopolymer Resin | High detail (50μm layer), smooth surface | Medical device prototypes, jewelry |

We also work with complementary materials like ABS, PLA, and nylon for multi-material projects—perfect for parts that need a mix of rigidity (PC) and flexibility (TPU).

Surface Treatment: Enhancing PC Parts’ Look and Performance

PC parts often need surface treatment to meet aesthetic or functional goals. Our services transform raw prints into polished, ready-to-use components:

- Sanding: Smooths rough surfaces (reduces Ra from 5–10μm to 1–2μm) for better paint adhesion.

- Painting & Coating: Applies durable paints (e.g., UV-resistant coatings) or epoxy coating for chemical resistance.

- Polishing: Creates a glossy finish (Ra <0.5μm) for consumer-facing parts (e.g., electronics casings).

- Texturing: Adds grip patterns or matte finishes to improve usability (e.g., sports equipment handles).

- Anodizing: For metal-infused PC parts, adds a corrosion-resistant layer (ideal for automotive components).

Table: Surface Treatment Impact on PC Part Performance

| Treatment | Surface Roughness (Ra) | Impact Resistance Improvement | Chemical Resistance |

| As-Printed | 5–10μm | Base (100%) | Low (resistant to water only) |

| Sanded + Painted | 1–2μm | +15% | Medium (resistant to oils) |

| Polished + Epoxy Coated | <0.5μm | +25% | High (resistant to solvents) |

Tolerances: Ensuring PC Parts Fit Perfectly

Dimensional accuracy is critical for PC parts—especially in industries like aerospace and medical devices. Our focus on tight tolerances sets us apart:

- Precision Tolerances: For FDM-printed PC parts, we achieve ±0.1mm for parts up to 100mm (±0.2mm for larger parts). SLA-printed PC resins offer even tighter tolerances (±0.05mm).

- Layer Thickness: We print PC at 0.05–0.3mm layer thickness—thinner layers (0.05mm) for high detail, thicker layers (0.3mm) for faster production.

- Minimizing Warping & Shrinkage: PC is prone to warping at high temperatures, so we use heated build plates (110–130°C) and enclosed printers to reduce shrinkage to <2% (industry average: 3–5%).

- Material Stability: Our PC materials undergo thermal testing to ensure they maintain shape and strength in temperatures up to 120°C (critical for automotive and industrial use).

For example, our PC aerospace brackets have a tolerance of ±0.08mm, meeting the strict standards of AS9100 (aerospace quality management).

Advantages: Why PC 3D Printing Beats Traditional Methods

PC 3D Printing offers a range of benefits that make it a top choice for modern manufacturing:

- Customization: Create one-of-a-kind parts (e.g., patient-specific medical device prototypes) without expensive molds.

- Rapid Prototyping: Test designs in days, cutting product development time by 50% compared to injection molding.

- Cost-Effective: For small batches (1–100 parts), PC 3D Printing costs 30–40% less than traditional machining.

- Reduced Waste: Additive manufacturing uses only the material needed, slashing waste to <5% (vs. 20–30% for machining).

- Complex Geometries: Print internal channels, overhangs, and lattice structures that are impossible with CNC machining.

- High Strength & Durability: PC parts have 2x the impact resistance of ABS, making them ideal for end-use parts (e.g., robotics components).

Table: PC 3D Printing vs. Traditional Manufacturing (for 50 PC Parts)

| Factor | PC 3D Printing (FDM) | Injection Molding | CNC Machining |

| Lead Time | 5 days | 4 weeks | 2 weeks |

| Cost | $1,500 | $5,000 (includes mold) | $3,000 |

| Waste | <5% | 10–15% | 25–30% |

| Design Flexibility | High (complex geometries) | Low (fixed mold) | Medium (limited by tooling) |

Applications Industry: Where PC 3D Printing Excels

PC’s strength, heat resistance, and versatility make it a staple across industries. Here’s how we’re using PC 3D Printing to solve real-world problems:

| Industry | Key Applications | Why PC? |

| Aerospace | Interior brackets, cable management parts | High strength-to-weight ratio, heat resistance |

| Automotive | Sensor housings, dashboard prototypes | Impact resistance, chemical resistance to oils |

| Consumer Electronics | Phone cases, laptop stands | Durability, sleek aesthetic potential |

| Medical Devices | Surgical tool handles, diagnostic equipment enclosures | Biocompatibility (medical-grade PC), easy sterilization |

| Robotics | Gear housings, structural frames | High rigidity, impact resistance |

| Sports Equipment | Helmet liners, bike components | Lightweight, shock absorption |

Manufacturing Techniques: Matching the Right Method to Your PC Project

We use a range of manufacturing techniques to optimize PC part production, from prototyping to mass manufacturing:

- Fused Deposition Modeling (FDM): The most common method for PC—ideal for large parts and low-to-medium volumes (1–500 units). Print speed: 30–80mm/s.

- Stereolithography (SLA): Best for high-detail PC resin parts (e.g., medical prototypes). Layer thickness: 25–100μm.

- Selective Laser Sintering (SLS): Uses PC powder to create strong, porous-free parts—great for industrial end-use parts (e.g., gears).

- Digital Light Processing (DLP): Similar to SLA but faster, using a digital light projector—ideal for small, detailed PC parts (e.g., jewelry).

- Multi-Jet Fusion: For high-volume PC production (1,000+ units), offering consistent part quality and fast turnaround.

Table: Technique Comparison for PC Parts

| Technique | Best For | Volume Range | Lead Time | Cost per Part (100 units) |

| FDM | Large, functional parts | 1–500 | 3–5 days | 20–50 |

| SLA | High-detail prototypes | 1–100 | 2–4 days | 30–70 |

| SLS | Durable end-use parts | 50–1,000 | 5–7 days | 40–80 |

| Multi-Jet Fusion | High-volume production | 1,000+ | 7–10 days | 10–30 |

Case Studies: PC 3D Printing in Action

Our PC 3D Printing solutions have helped clients overcome manufacturing challenges and achieve their goals:

Case Study 1: Automotive Sensor Housing

- Client: A global automotive supplier.

- Challenge: Need a heat-resistant, impact-proof housing for engine sensors (traditional ABS parts failed in high temperatures).

- Solution: FDM-printed PC housing with a glass fiber reinforcement (for extra stiffness) and epoxy coating (for chemical resistance).

- Results: 0% failure rate in 6 months of testing (vs. 15% for ABS), 20% cost savings vs. injection molding, and 2-week lead time (vs. 4 weeks).

Case Study 2: Medical Diagnostic Equipment Enclosure

- Client: A medical device startup.

- Challenge: Develop a lightweight, sterilizable enclosure for a portable ultrasound machine (needed to fit tight dimensions).

- Solution: SLA-printed medical-grade PC resin enclosure with a polished finish (for easy cleaning) and UV-curing (for durability).

- Results: Met FDA biocompatibility standards, 30% lighter than aluminum enclosures, and 50% faster prototyping than machining.

Case Study 3: Robotics Gear Housing

- Client: A robotics company.

- Challenge: Create a gear housing that can withstand high torque and impact (CNC-machined aluminum was too heavy).

- Solution: SLS-printed carbon fiber reinforced PC housing—optimized for complex geometries to reduce weight.

Results: 40% weight reduction, 15% higher torque resistance than aluminum, and $1,200 cost savings for 50 units.

Why Choose Us: Your Trusted PC 3D Printing Partner

With so many 3D printing providers, here’s why Yigu Technology stands out for PC projects:

- Expertise in PC: Our engineers have 8+ years of experience working with Polycarbonate—we know how to avoid common pitfalls (e.g., warping, poor layer adhesion) to deliver top-quality parts.

- Advanced Technology: We use state-of-the-art machines (e.g., Ultimaker S5 for FDM, Formlabs Form 4 for SLA) calibrated specifically for PC materials.

- Custom Solutions: We don’t just print parts—we work with you to optimize designs for PC’s properties, ensuring the final product meets your functional and aesthetic needs.

- Fast Turnaround: Our average lead time for PC parts is 3–5 days, with rush options available for urgent projects.

- Proven Track Record: We’ve delivered 10,000+ PC parts to clients in aerospace, automotive, and medical industries—with a 98% satisfaction rate.

Competitive Pricing: We offer volume discounts (up to 25% off for 500+ parts) and transparent pricing with no hidden fees.