Se sei uno specialista degli appalti o un ingegnere di prodotto nel campo della robotica, mastering themetal robot prototype model process is key to turning design ideas into functional, robot affidabili. I prototipi in metallo ti consentono di testare la durabilità, movimento, e stabilità strutturale, fondamentale per evitare errori costosi nella produzione di massa. Di seguito è riportato un pratico, analisi dettagliata di ogni fase, with real cases and data to help you make smart decisions.

1. Selezione dei materiali: Pick Metals That Fit Robot Needs

Choosing the right metal is the first big step in building ametal robot prototype. Robots need materials that balance strength, peso, and cost—here’s how to choose:

| Metal Type | Proprietà chiave | Ideal Robot Components | Esempio del mondo reale | Fascia di costo (USD/libbra) |

|---|---|---|---|---|

| Lega di alluminio | Bassa densità (2.7 g/cm³), facile da lavorare | Arm joints, telai leggeri | A factory robot maker used 6061 aluminum for arm prototypes—cut weight by 35% contro. acciaio, improving movement speed. | $2–$5 |

| Acciaio inossidabile | Resistente alla corrosione, alta resistenza | Grippers, outdoor robot bodies | A warehouse robot prototype used 316 stainless steel for grippers—no rust after 8 months of handling wet packages. | $3–$8 |

| Ottone | Buona conduttività elettrica | Sensor mounts, small connectors | A service robot team used brass for sensor prototypes—ensured stable signal transmission during tests. | $8–$12 |

| Magnesium Alloy | Ultraleggero, elevata rigidità | Small robot frames (per esempio., droni) | A medical robot prototype used magnesium alloy for its body—weighed 20% meno dell'alluminio, ideal for tight spaces. | $10–$15 |

| Zinc Alloy | Basso costo, buona colabilità | Decorative covers, parti semplici | A toy robot company used zinc alloy for prototype covers—saved 40% on material costs vs. alluminio. | $1.5–$4 |

Tip for procurement: For robots that move often (per esempio., factory arms), aluminum alloy is the best mix of cost and performance. Per uso esterno, stainless steel is a must.

2. Data Collection: Lay the Groundwork for Accuracy

You can’t build a good prototype without clear data. This stage ensures your prototype matches your design exactly.

2.1 Import 3D/CAD Files

Ask your design team or client for3D drawings or CAD files—these are the blueprint for your prototype. Senza di loro, you risk misinterpreting sizes or shapes.

Common tools: AutoCAD (for 2D files), SolidWorks (for 3D models), Fusione 360 (great for small teams).

Esempio: A robot startup once skipped checking CAD files—their prototype’s arm joint was 1mm too small, so it couldn’t move smoothly. Always verify file details first!

2.2 Create Initial Prototypes

Turn 2D/3D files into simple prototypes to test basic fit. Two common methods:

- SLA Laser Rapid Prototyping: Veloce (1–2 giorni) per piccoli, parti dettagliate (per esempio., staffe per sensori).

- Lavorazione CNC: Better for larger, sturdier parts (per esempio., robot frames).

Caso: A logistics robot team used SLA to make gripper prototypes—they realized the grippers were too narrow for boxes, fixing the issue before full machining.

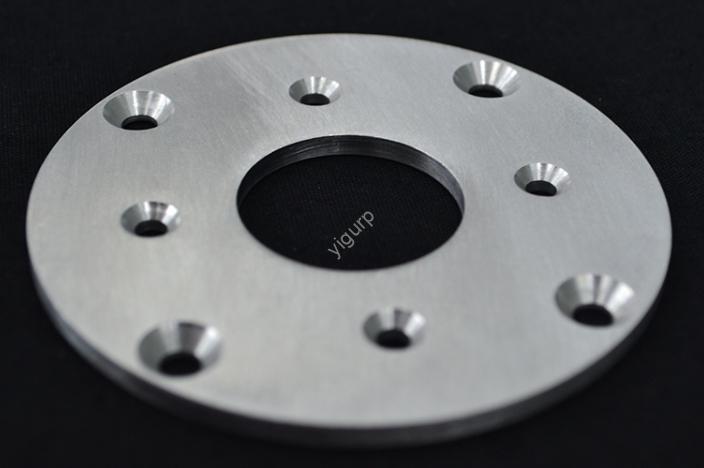

3. Lavorazione CNC: Turn Metal into Robot Parts

CNC machines are the heart ofmetal robot prototype manufacturing—they make precise parts quickly.

3.1 Programmazione & Impostare

Engineers write code for the CNC machine using your 3D/2D files. This code tells the machine how to cut, trapano, and shape the metal.

Key benefits:

- Alta precisione (tolerances as tight as ±0.001mm) – critical for robot joints that need smooth movement.

- Consistent results – every part is the same, so assembly is easy.

Esempio: A factory robot maker used CNC programming for arm prototypes—all 10 parts fit perfectly, nessuna rilavorazione necessaria.

3.2 Lavorazione multiasse

Per parti complesse (per esempio., curved robot bodies or multi-angle joints), utilizzomulti-axis CNC machines (3-asse, 5-asse, o più).

- 3-macchine ad assi: Good for simple parts (per esempio., flat frames).

- 5-macchine ad assi: Reach hard-to-access areas (per esempio., inside arm joints) – cuts production time by 30% contro. 3-asse.

Stat: 5-axis machining reduces prototype errors by 50% rispetto ai metodi tradizionali (per robotics manufacturing data).

4. Manual Processing: Fix Small Flaws

Even CNC parts need a little hands-on work to be perfect.

4.1 Sbavatura

Usa la carta vetrata, deburring tools, or brushes to smoothsharp edges and knife marks on metal parts. This prevents scratches on other components or workers.

Why it matters: A robot arm prototype once had a sharp edge—during testing, it scratched a conveyor belt. Deburring fixes this easy-to-miss issue.

4.2 Rettifica & Lucidatura

Check your drawings to ensure the surface is smooth enough. Per esempio:

- Robot joints need polished surfaces to move without friction.

- External covers need grinding to look neat.

Esempio: A service robot team polished their prototype’s body—testers said the smooth surface was easier to clean, a big plus for public spaces.

5. Appearance Treatment: Boost Durability & Looks

Robots need to last and look good—surface treatment does both.

Key Surface Processes for Metal Robot Prototypes

| Processo | Scopo | Ideal Robot Components |

|---|---|---|

| Pittura | Aggiungi colore, hide scratches | External bodies, covers |

| Sabbiatura | Create a matte, superficie antiscivolo | Grippers, foot pads |

| Ossidazione | Prevent rust (per parti in alluminio) | Arm joints, cornici |

| Incisione laser | Add logos or labels (per esempio., “Power”) | Pannelli di controllo |

| Silk Screen Printing | Add text (per esempio., “Caution”) | Safety covers, pulsanti |

Caso: An outdoor robot company used oxidation on aluminum arm prototypes—after 6 months in rain and snow, there was no rust, and the arms moved like new.

6. Assemblea & Test: Make Sure the Robot Works

Put all parts together, then test if the prototype functions as planned.

6.1 Test Assembly

Primo, assemble the prototype to check:

- Do parts fit? (per esempio., Does the arm attach to the body correctly?)

- Is the structure stable? (per esempio., Can the robot hold 5kg without tipping?)

Esempio: A medical robot team tested assembly and found the sensor mount was misaligned—they adjusted it, avoiding a failure in functional tests.

6.2 Test funzionali

Test how the prototype performs in real situations:

- Structural stability: Shake the robot to see if parts loosen.

- Mechanical properties: Check if joints move smoothly (per esempio., Can the arm lift 3kg 100 times?).

- Simulated use: Run the robot in a test environment (per esempio., a factory robot moving boxes).

Caso: A warehouse robot prototype failed a simulated use test—it couldn’t grip wet boxes. The team added a rubber layer to the grippers, fixing the problem.

7. Confezione & Shipping: Protect Your Prototype

Don’t ruin your hard work with bad packaging.

- Safe packaging: Use foam, bubble wrap, or custom boxes to prevent damage. Per esempio, robot arms need rigid packaging to avoid bending.

- Consegna puntuale: Work with reliable logistics to meet deadlines. Most robotics teams need prototypes in 2–3 weeks to stay on schedule.

Tip: Add a packing list—this helps clients check if all parts (per esempio., viti, sensori) arrive.

La prospettiva della tecnologia Yigu

Alla tecnologia Yigu, we know themetal robot prototype model process thrives on precision and practicality. Many teams overcomplicate it—like using 5-axis machining for simple frames when 3-axis works. We work with clients to pick materials (per esempio., aluminum for moving parts, stainless steel for outdoors) and processes that fit their goals. Our manual processing and testing teams focus on real use: we don’t just build prototypes—we build robots that work when it matters. This balance saves time, cuts costs, and gives clients confidence in their final product.

Domande frequenti

- Q: How long does it take to make a metal robot prototype?

UN: It depends on complexity. Piccole parti (per esempio., staffe per sensori) impiegare 1-2 settimane. A full robot prototype (per esempio., a factory arm) takes 3–4 weeks, compresa la progettazione e il test. - Q: Which material is best for a metal robot prototype on a tight budget?

UN: Zinc alloy or aluminum alloy (6061 grado). Zinc is cheap for simple parts, Mentre 6061 aluminum is affordable and works for most moving components. - Q: Do I need to test assembly before functional testing?

UN: SÌ! Assembly testing catches fit issues (per esempio., misaligned parts) that functional tests might miss. Skipping it can waste time—fixing assembly problems later takes 2x longer.