Se lavori in settori come quello automobilistico, minerario, o aerospaziale, comprendi l'importanza di un acciaio per cuscinetti affidabile. Acciaio per cuscinetti EN 100CrMo7—una lega standard europea con aggiunta di molibdeno—si distingue per la sua eccellente resistenza alla fatica e temprabilità. Questa guida ti guiderà attraverso le sue proprietà chiave, applicazioni del mondo reale, processo di produzione, e come si confronta con altri materiali, aiutandoti a prendere decisioni informate per i tuoi progetti.

1. Proprietà dei materiali dell'acciaio per cuscinetti EN 100CrMo7

La composizione unica di EN 100CrMo7, soprattutto l'aggiunta di molibdeno, offre vantaggi distinti rispetto agli acciai per cuscinetti standard. Analizziamo le sue proprietà nel dettaglio.

1.1 Composizione chimica

EN 100CrMo7 segue i rigorosi standard europei (IN 10083-3), garantendo una qualità costante. Di seguito è riportata la sua tipica composizione chimica:

| Elemento | Simbolo | Gamma di contenuti (%) | Ruolo chiave |

| Carbonio (C) | C | 0.95 – 1.05 | Migliora la durezza e la resistenza all'usura |

| Cromo (Cr) | Cr | 1.50 – 1.80 | Migliora la temprabilità e la resistenza alla fatica |

| Molibdeno (Mo) | Mo | 0.15 – 0.25 | Aumenta la resistenza e la tenacità alle alte temperature |

| Manganese (Mn) | Mn | 0.25 – 0.45 | Aumenta la resistenza alla trazione e la lavorabilità |

| Silicio (E) | E | 0.15 – 0.35 | Aiuta la disossidazione durante la produzione dell'acciaio |

| Zolfo (S) | S | ≤ 0.025 | Ridotto al minimo per evitare fragilità |

| Fosforo (P) | P | ≤ 0.025 | Controllato per evitare fessurazioni |

| Nichel (In) | In | ≤ 0.30 | Quantità in tracce per un lieve miglioramento della duttilità |

| Rame (Cu) | Cu | ≤ 0.25 | Oligoelemento senza grande impatto sulle prestazioni |

| Vanadio (V) | V | ≤ 0.05 | Importo della traccia, può migliorare l'affinamento del grano |

1.2 Proprietà fisiche

Queste proprietà descrivono come si comporta l'EN 100CrMo7 in condizioni fisiche come temperatura e magnetismo:

- Densità: 7.85 g/cm³ (come la maggior parte degli acciai al carbonio-cromo-molibdeno)

- Punto di fusione: 1,410 – 1,450 °C (2,570 – 2,640 °F)

- Conducibilità termica: 45.5 Con/(m·K) A 20 °C (temperatura ambiente)

- Coefficiente di dilatazione termica: 11.4 × 10⁻⁶/°C (da 20 – 100 °C)

- Proprietà magnetiche: Ferromagnetico (attira i magneti), facilitandone l'ordinamento e l'ispezione.

1.3 Proprietà meccaniche

Le proprietà meccaniche determinano le prestazioni dell'EN 100CrMo7 sotto sforzo. Tutti i valori riportati di seguito sono misurati dopo il trattamento termico standard (tempra e rinvenimento):

| Proprietà | Metodo di misurazione | Valore tipico |

| Durezza (Rockwell) | HRC | 61 – 65 HRC |

| Durezza (Vickers) | alta tensione | 660 – 710 alta tensione |

| Resistenza alla trazione | MPa | ≥ 2,100 MPa |

| Forza di snervamento | MPa | ≥ 1,900 MPa |

| Allungamento | % (In 50 mm) | ≤ 7% |

| Resistenza all'impatto | J (A 20 °C) | ≥ 18 J |

| Limite di fatica | MPa (raggio rotante) | ≥ 1,000 MPa |

1.4 Altre proprietà

Le straordinarie proprietà dell'EN 100CrMo7 lo rendono ideale per applicazioni ad alta richiesta:

- Resistenza all'usura: L'alto contenuto di carbonio e il cromo formano carburi duri, riducendo l'usura dovuta al contatto volvente o strisciante.

- Resistenza alla fatica: Il molibdeno migliora la sua capacità di resistere a milioni di cicli di carico, fondamentale per i cuscinetti di lunga durata nei macchinari pesanti.

- Resistenza alla corrosione: Moderare; richiede rivestimenti (come la zincatura o la nitrurazione) per ambienti umidi o difficili (inferiore all'acciaio inossidabile).

- Temprabilità: Eccellente: può essere trattato termicamente per uniformare la durezza anche in sezioni spesse, garantendo prestazioni costanti in componenti di grandi dimensioni.

- Stabilità dimensionale: Mantiene la forma anche sotto sbalzi termici e stress, perfetto per parti di precisione come le piste dei cuscinetti.

2. Applicazioni dell'acciaio per cuscinetti EN 100CrMo7

La combinazione di forza dell’EN 100CrMo7, tenacità, e la resistenza all'usura lo rendono adatto ad un'ampia gamma di applicazioni ad alto stress. Ecco i suoi usi più comuni:

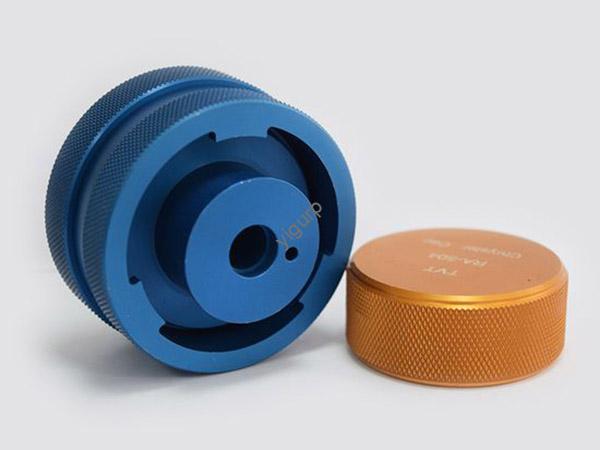

- Cuscinetti: L'applicazione principale: compresi i cuscinetti a sfere per carichi pesanti, cuscinetti a rulli, e cuscinetti ad aghi per macchinari industriali e attrezzature minerarie.

- Elementi rotanti: Palle, rulli, o gli aghi all'interno dei cuscinetti si affidano alla resistenza all'usura dell'EN 100CrMo7 per gestire carichi pesanti.

- Razze: Anelli interni ed esterni dei cuscinetti (dove si muovono gli elementi volventi) sono spesso realizzati con questo acciaio per una maggiore durata.

- Componenti automobilistici: Parti soggette a sollecitazioni elevate come gli alberi a camme, alzavalvole, e ingranaggi di trasmissione, soprattutto negli autocarri pesanti.

- Macchinari industriali: Riduttori, sistemi di trasporto, e pompe che funzionano con carichi elevati e per lunghe ore.

- Componenti aerospaziali: Cuscinetti piccoli ma critici negli accessori dei motori degli aerei e nei carrelli di atterraggio (dove l’affidabilità non è negoziabile).

- Dispositivi medici: Cuscinetti di precisione negli strumenti chirurgici e nelle apparecchiature diagnostiche (grazie alla sua stabilità dimensionale).

- Motori elettrici: Cuscinetti di grandi motori industriali che generano calore elevato (beneficiando della resistenza alle alte temperature del molibdeno).

- Macchine agricole: Cuscinetti di trattori e mietitrici che movimentano polvere, condizioni di carico elevato.

- Attrezzature minerarie: Cuscinetti in frantoi e nastri trasportatori, dove la resistenza all'usura e agli urti è essenziale.

3. Tecniche di produzione per EN 100CrMo7

La produzione di EN 100CrMo7 richiede passaggi precisi per soddisfare gli standard europei e garantire prestazioni ottimali. Ecco il tipico processo di produzione:

- Produzione dell'acciaio:

- La maggior parte dell'EN 100CrMo7 viene prodotta utilizzando un Forno ad arco elettrico (EAF) (per il riciclaggio dei rottami di acciaio) o a Fornace ad ossigeno basico (BOF) (per la produzione a base di minerale di ferro). Il processo si concentra sulla regolazione della composizione chimica, in particolare sull'aggiunta di molibdeno, per soddisfare le norme EN 10083-3 requisiti.

- Rotolamento:

- Dopo la produzione dell'acciaio, il metallo è Laminato a caldo (A 1,100 – 1,200 °C) in billette, bar, o fogli per modellarlo. Per pezzi di precisione, è allora Laminato a freddo (a temperatura ambiente) per migliorare la finitura superficiale e la precisione dimensionale.

- Trattamento termico:

- Questo passaggio è fondamentale per sfruttare appieno il potenziale dell’EN 100CrMo7:

- Tempra: Riscaldare l'acciaio 830 – 870 °C, quindi raffreddarlo rapidamente in olio o acqua per indurirlo.

- Temperamento: Riscaldare a 160 – 220 °C per ridurre la fragilità mantenendo elevata durezza e tenacità.

- Carburazione: A volte utilizzato per parti che necessitano di uno strato esterno duro (per esempio., denti dell'ingranaggio)—calore in un'atmosfera ricca di carbonio per aumentare il contenuto di carbonio superficiale.

- Forgiatura di precisione:

- Per forme complesse (come i componenti dei cuscinetti personalizzati), l'acciaio viene riscaldato e forgiato in forme quasi definitive. Ciò migliora la struttura del grano e migliora le proprietà meccaniche.

- Lavorazione:

- Trattamento post-termico, le parti vengono lavorate alle dimensioni finali utilizzando Girando (per parti cilindriche come le piste dei cuscinetti) O Rettifica (per superfici ultra lisce, che riducono l'attrito nei cuscinetti).

- Trattamento superficiale:

- Passaggi facoltativi per migliorare le prestazioni:

- Nitrurazione: Crea uno strato esterno duro per aumentare la resistenza all'usura e alla corrosione.

- Annerimento: Forma uno strato protettivo di ossido per prevenire la ruggine minore.

- Controllo qualità:

- I controlli rigorosi garantiscono la qualità:

- Analisi chimica (per verificare il contenuto dell'elemento).

- Test di durezza (utilizzando macchine Rockwell o Vickers).

- Prove non distruttive (test ad ultrasuoni per rilevare crepe interne).

- Controlli dimensionali (utilizzando calibri o strumenti di misurazione CNC per garantire l'adattamento delle parti).

4. Casi di studio: EN 100CrMo7 in azione

Gli esempi del mondo reale evidenziano come l’EN 100CrMo7 risolve le sfide del settore.

Caso di studio 1: Affidabilità dei cuscinetti delle attrezzature minerarie

Una società mineraria si trovava a dover affrontare frequenti guasti ai cuscinetti dei propri sistemi di nastri trasportatori (solo duraturo 3 mesi). I cuscinetti originali utilizzavano acciaio standard 100Cr6, che non è in grado di sopportare l'impatto elevato e la polvere. Il passaggio ai cuscinetti EN 100CrMo7, abbinati al trattamento superficiale di nitrurazione, ha prolungato la durata dei cuscinetti fino a 12 mesi. Ciò ha ridotto i tempi di inattività per manutenzione 75% e ridurre i costi di sostituzione 60%.

Caso di studio 2: Durata dei cuscinetti del motore elettrico

Un produttore di grandi motori industriali ha notato il cedimento dei cuscinetti 10,000 ore di utilizzo (a causa del calore elevato). Sono passati ai cuscinetti EN 100CrMo7, che beneficiano della resistenza alle alte temperature del molibdeno. Post-switch, la durata dei cuscinetti è aumentata a 25,000 ore, e l'azienda si è salvata $200,000 annualmente nei costi di manutenzione.

5. EN100CrMo7 rispetto a. Altri materiali per cuscinetti

Come si confronta l'EN 100CrMo7 con altri comuni acciai e materiali per cuscinetti?? La tabella seguente analizza le principali differenze:

| Materiale | Somiglianze con EN 100CrMo7 | Differenze chiave | Ideale per |

| AISI 52100 | Alto contenuto di carbonio/cromo; utilizzato per i cuscinetti | Niente molibdeno; minore resistenza alle alte temperature | Macchinari automobilistici e leggeri standard |

| HE SUJ2 | Contenuto simile di carbonio/cromo; resistente all'usura | Niente molibdeno; Standard giapponese | Automotive ed elettronica giapponese |

| GCr15 | Lega di carbonio/cromo; grado di cuscinetto | Niente molibdeno; Standard cinese | Macchinari industriali cinesi |

| 100Cr6 | Norma europea; grado di cuscinetto | Niente molibdeno; minore resistenza alla fatica | Applicazioni industriali da leggere a medie |

| Cuscinetti in acciaio inossidabile (AISI440C) | Resistente all'usura | Migliore resistenza alla corrosione; minore resistenza alla trazione | Ambienti umidi (lavorazione degli alimenti, marino) |

| Cuscinetti in ceramica (Nitruro di silicio) | Bassa usura | Più leggero; maggiore resistenza al calore; molto più costoso | Ad alta velocità, app ad alta temperatura (corsa, aerospaziale) |

| Cuscinetti in plastica (PTFE) | Resistente alla corrosione | Più economico; bassa forza; non per carichi pesanti | Basso carico, usi a bassa velocità (elettrodomestici) |

| Cuscinetti in acciaio ad alta velocità (M2) | Resistenza alle alte temperature | Più costoso; minore resistenza all'usura | Utensili da taglio e macchinari ad alta velocità |

La prospettiva di Yigu Technology su EN 100CrMo7

Alla tecnologia Yigu, EN 100CrMo7 è la nostra prima scelta per i clienti del settore minerario, automobilistico pesante, e macchinari industriali. L'aggiunta di molibdeno gli conferisce una resistenza alla fatica senza pari e prestazioni alle alte temperature, fondamentali per gli ambienti difficili. Lo abbiniamo a forgiatura e nitrurazione di precisione per massimizzare la durata, fornendo parti che durano 2-3 volte più a lungo rispetto allo standard 100Cr6. Per i clienti che necessitano di affidabilità, cuscinetti a bassa manutenzione, EN 100CrMo7 è una soluzione conveniente che riduce al minimo i tempi di fermo e i costi di sostituzione.

Domande frequenti sull'acciaio per cuscinetti EN 100CrMo7

- Perché viene aggiunto molibdeno all'EN 100CrMo7?

Il molibdeno migliora la resistenza alle alte temperature e la tenacità dell'EN 100CrMo7, rendendolo adatto per applicazioni come attrezzature minerarie e motori industriali che generano calore o subiscono impatti pesanti.

- L'EN 100CrMo7 può essere utilizzato in ambienti corrosivi?

Ha una moderata resistenza alla corrosione. Per ambienti umidi o corrosivi (per esempio., lavorazione marina o alimentare), applicare un trattamento superficiale come nitrurazione o zincatura per prevenire la ruggine e prolungare la durata.

- Come si confronta EN 100CrMo7 con 100Cr6?

EN 100CrMo7 ha aggiunto molibdeno, che aumenta la resistenza alla fatica e la resistenza alle alte temperature. È meglio per i lavori pesanti, applicazioni ad alto stress (minerario, camion pesanti), mentre 100Cr6 è ideale per usi più leggeri (macchinari leggeri, piccoli motori).