From Design to Reality

The journey from a carefully designed computer model to a real, l'oggetto fisico è uno dei passaggi più importanti nella creazione di un prodotto. È qui che la tua idea digitale incontra il mondo reale. Un produttore di prototipi rapidi è il partner che aiuta a realizzare tutto ciò, turning your designs into working prototypes for testing and presentation. Their job goes far beyond just making things; they are a key part of the entire product creation process.

Picking the right partner is a decision that greatly affects whether your project succeeds. This choice impacts everything from how quickly you get to market and staying within budget to the final quality of your product. A good manufacturer works with you as a teammate, offering knowledge that helps validate your design and reduce important risks. A bad choice can cause delays, cost overruns, and a prototype that doesn’t meet your goals. This guide gives you a complete framework to help you navigate this selection process. We will cover the main criteria for evaluating manufacturers, compare key prototyping technologies, look at the balance between cost and quality, and review real-world case studies to help you find the perfect partner for your project.

Core Selection Criteria

Evaluating potential rapid prototype manufacturers requires an organized approach. Moving beyond surface-level impressions and marketing claims is essential to finding a partner who can truly deliver. We have developed a framework based on four key areas: technical capabilities, competenza materiale, quality systems, e comunicazione. Judging a manufacturer against these criteria will give you a clear, complete view of how suitable they are for your specific project needs. This section provides the detailed questions you should be asking and the warning signs to watch for, helping you make a confident, informed decision.

Technical Capabilities and Tech

A manufacturer’s technology collection is the foundation of their service. The main goal is to make sure their capabilities match perfectly with your project’s requirements. A design for a high-precision medical device has very different needs than a simple shape model for a consumer product. You must verify that they have the right tools for your job.

Start by asking about their equipment. Do they own their machines, or do they outsource to a network of third parties? In-house ownership often means better control over quality, scheduling, and process consistency. Ask about their machine maintenance schedules; well-maintained equipment is crucial for achieving tight tolerances and consistent results. A manufacturer who is open about their technology and maintenance shows a commitment to quality.

- What specific manufacturing technologies do you have in-house (per esempio., SLA, SLS, 5-asse CNC)?

- What is the build volume and typical tolerance of your key machines?

- Can you provide a full equipment list?

- How do you ensure your machines are calibrated and maintained?

Material Expertise and Availability

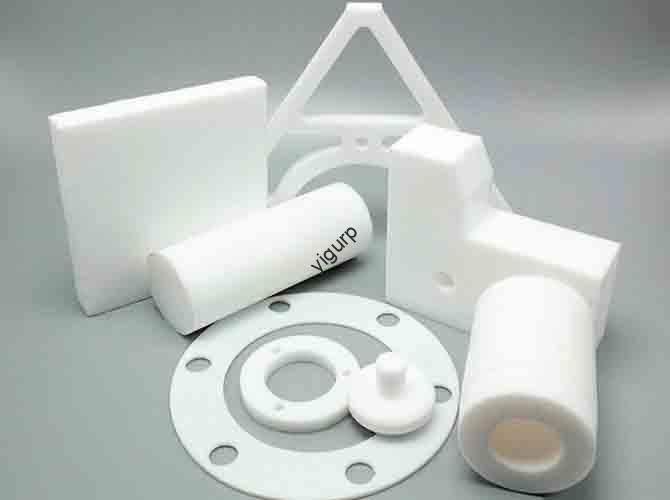

The material you choose determines the functional and aesthetic properties of your prototype. It controls everything from its strength and flexibility to its heat resistance and biocompatibility. A great rapid prototype manufacturer doesn’t just show a list of materials; they provide expert guidance to help you select the best one for your application. They should understand the details of different polymers, metalli, and resins and be able to explain the trade-offs between them in the context of your project.

Their ability to source materials is also critical. While a standard stock of common materials is expected, complex projects may require specialized or custom-ordered substances. A partner with a strong supply chain and a willingness to source unique materials is invaluable.

- What is your full range of available stock materials?

- Can you provide material specification sheets (datasheets) for your offerings?

- What is your process for sourcing custom or non-stock materials?

- Can you offer guidance on material selection based on my functional requirements (per esempio., Stabilità ai raggi UV, resistenza chimica)?

Quality Control and Certs

A strong Quality Management System (QMS) is the hallmark of a professional manufacturing operation. It is the set of processes that ensures the final part meets the specifications outlined in your CAD file and drawings. This is not something to be taken for granted. Look for evidence of a structured quality process, which typically includes in-process inspections (checks made during manufacturing) and a thorough final inspection before shipping.

Industry certifications are a powerful, third-party validation of a manufacturer’s commitment to quality. The most common and important is ISO 9001, which means that the company has a well-documented and consistently followed QMS. For projects in more demanding sectors, look for specialized certifications. Per esempio, AS9100 is the standard for the aerospace industry, indicating an even higher level of process control, tracciabilità, and risk management. Always ask for proof of certification and inquire about their standard inspection procedures.

- Are you ISO 9001 certificato? Can you provide a copy of your certificate?

- What does your standard inspection process involve?

- Do you provide inspection reports and a Certificate of Conformity with shipments?

- How do you handle non-conforming parts?

Communication and Project Management

In our experience, a dedicated project manager is essential for complex projects. A single point of contact prevents miscommunication, streamlines decision-making, and ensures accountability from quoting to delivery. The quality of communication is often a direct reflection of how organized and customer-focused the manufacturer is.

From your very first interaction, pay attention to their responsiveness and the clarity of their answers. Do they respond to your request for quote promptly? Are their answers thorough, or do they avoid difficult questions? A good partner is proactive. They should provide regular, unsolicited updates on your project’s status and immediately flag any potential issues or delays. This transparency builds trust and allows you to manage your project timeline effectively. Vague communication and slow response times during the quoting phase are major warning signs that will only worsen once an order is placed.

Your Ultimate Vetting Checklist

Use this checklist to systematically evaluate and compare potential manufacturing partners.

Category: Capacità & Competenza

- ☐ Do their in-house technologies match my project’s complexity and precision needs?

- ☐ Have they demonstrated deep expertise in my required materials?

- ☐ Can they provide guidance on technology and material selection?

- ☐ Do they own and maintain their own equipment?

Category: Qualità & Trust

- ☐ Are they ISO 9001 certified or hold other relevant industry certifications (per esempio., AS9100)?

- ☐ Can they provide a sample quality inspection report?

- ☐ Have they clearly explained their Quality Management System (QMS)?

- ☐ Do they offer material datasheets and Certificates of Conformity?

Category: Partenariato & Processo

- ☐ Is their communication style clear, professional, and responsive?

- ☐ Will I have a dedicated project manager or single point of contact?

- ☐ Have they provided clear, detailed lead times and cost breakdowns?

- ☐ Do they offer Design for Manufacturability (DFM) feedback?

Matching Technologies to Projects

The term “prototipazione rapida” includes a wide array of manufacturing technologies, ognuno con punti di forza unici, punti deboli, and ideal applications. Understanding the basics of these processes is crucial for having a productive conversation with a manufacturer and for ensuring the right technology is chosen for your project. The three main categories are additive (costruire strato dopo strato), sottrattivo (carving from a solid block), and formative (using a mold or pattern). A capable rapid prototype manufacturer will typically offer services across multiple categories.

Produzione additiva (3D Stampa)

Additive manufacturing builds parts layer by layer directly from a 3D model. This category has revolutionized prototyping by enabling the creation of highly complex shapes that are impossible to produce with traditional methods.

- Stereolitografia (SLA): This process uses a UV laser to cure liquid photopolymer resin. It is known for producing parts with exceptional detail and a very smooth surface finish, making it ideal for visual models, marketing samples, and form-fit testing where appearance is most important.

- Sinterizzazione laser selettiva (SLS): SLS uses a high-power laser to fuse powdered material, typically nylon. Its key advantage is that it requires no support structures, as the unfused powder supports the part during printing. This allows for intricate internal features and complex shapes. SLS parts are strong and functional, making them excellent for prototypes that need to withstand mechanical stress, such as snap-fits or living hinges.

- Modellazione della deposizione fusa (FDM): FDM is the most widely recognized 3D printing technology. It works by extruding a thermoplastic filament layer by layer. Its primary benefits are low cost, high speed for simple parts, and a wide variety of available production-grade thermoplastics. FDM is best for early-stage concepts, basic proof-of-concept models, e grande, simple parts where fine detail is not the main priority.

- Fusione multigetto (mjf): Developed by HP, MJF is a powder-bed fusion process similar to SLS but uses a fusing agent and detailing agent to achieve high speeds. It produces strong, functional parts with good detail and consistent mechanical properties, making it an excellent choice for functional prototypes and medium-sized production batches.

Produzione sottrattiva

Unlike additive methods, subtractive manufacturing starts with a solid block of material (UN “vuoto”) and removes material using cutting tools to achieve the final shape.

- Lavorazione CNC: Controllo numerico computerizzato (CNC) machining offers the highest level of precision and can work with a vast range of production-grade materials, compresi i metalli (alluminio, acciaio, titanio) and engineering plastics (ABS, policarbonato, SBIRCIARE). Because it uses real production materials, it is the best choice for functional prototypes that require tight tolerances, superior material strength, and properties identical to the final production part.

Formative Manufacturing

Formative processes use a master pattern or tool to shape the final part. This is ideal when you need a small batch of identical prototypes.

- Urethane Casting: This process involves creating a silicone mold from a master pattern (often made with SLA or CNC). Liquid polyurethane is then poured into the mold to create high-quality copies. Urethane casting is perfect for pre-production runs, marketing samples, or user testing where you need 10-100 identical units without investing in expensive injection molding tools. The parts have an excellent surface finish and can be produced in a wide variety of colors and textures.

Technology Comparison at a Glance

This table provides a quick reference for comparing the most common rapid prototyping technologies.

| Tecnologia | Primary Materials | Tolleranza tipica | Finitura superficiale | Costo per parte | Ideale per… |

| SLA | Photopolymer Resins | ±0,1 mm | Very Smooth | Medio | High-detail visual models, master patterns |

| SLS | Nylon Powders (PA11, PA12) | ±0.25 mm | Slightly Grainy | Medio-Alto | Complesso, durable functional parts, snap-fits |

| FDM | Termoplastici (ABS, PLA, computer) | ±0.3 mm | Visible Layer Lines | Basso | Early concepts, proof-of-concept models |

| mjf | Nylon Powders (PA12) | ±0,2 mm | Smooth but Matte | Medio | Prototipi funzionali, lotti medi |

| CNC | Metalli, Ingegneria delle materie plastiche | ±0,025 mm | Eccellente | Alto | Alta precisione, parti ad alta resistenza |

| Urethane Casting | Polyurethanes | ±0.3% of nominal size | Eccellente | Basso (in volume) | Low-volume production runs (10-100 unità) |

Balancing Cost Versus Quality

In rapid prototyping, the saying “you get what you pay for” often holds true. While managing a budget is a critical project constraint, selecting a partner based solely on the lowest price is one of the most common and costly mistakes. A cheap prototype that fails, is delivered late, or is dimensionally inaccurate provides no value and can set your project back weeks. The goal is not to find the cheapest option, but the best value. This means understanding what drives cost and how to analyze quotes to see beyond the price tag.

What Drives Prototyping Cost?

Several key factors influence the price of a prototype. Understanding them helps you design more cost-effective parts and evaluate whether a quote is reasonable.

- Material Choice: The cost of raw material varies significantly. A part made from PEEK or stainless steel will be far more expensive than one made from ABS plastic.

- Part Complexity & Misurare: Price is heavily influenced by machine time. Larger parts or those with highly complex shapes require longer print or machining times, directly increasing the cost.

- Technology Used: The manufacturing process itself is a major cost driver. CNC machining is generally more expensive per hour than FDM 3D printing due to machine cost, setup time, and tooling.

- Labor & Post-elaborazione: The cost includes the human effort required for file preparation, configurazione della macchina, and post-processing steps like support removal, levigatura, pittura, or tapping threads. These finishing steps can add significant cost.

- Tempi di consegna: Speed comes at a price. Rush orders require shuffling production schedules and often running machines on overtime, which always costs extra.

Decoding Your Quote

When you receive quotes from multiple manufacturers, they can be difficult to compare. A low price might hide missing services, while a high price might include valuable extras. Use this practical framework to compare quotes on an equal basis.

- Fare un passo 1: Verify the Core Specs. The most basic check. Does the quote clearly list the correct material, tecnologia, quantità, and part revision you requested? A simple typo here can lead to a completely incorrect part.

- Fare un passo 2: Scrutinize Post-Processing. This is where hidden costs often lie. Does your part require a smooth, painted finish? Do you need threads tapped or inserts installed? Confirm whether these finishing steps are included in the price or listed as separate line items. One quote might seem cheaper because it assumes a raw, unfinished part.

- Fare un passo 3: Analyze the Lead Time. A lead time can be an “estimate” o a “guaranteed ship date.” Clarify this. What are the manufacturer’s policies if they miss the ship date? A reliable partner will stand by their timeline. An unreliable one may offer an optimistic lead time to win the business, only to delay the shipment later.

- Fare un passo 4: Look for Value-Added Services. This is where a great rapid prototype manufacturer distinguishes itself. Does the quote include free Design for Manufacturability (DFM) feedback? This expert analysis of your design can identify potential problems—such as thin walls that might break or features that are difficult to machine—before manufacturing begins. This advice can save you thousands of dollars in costly redesigns and failed parts.

- Fare un passo 5: Understand the “Why.” If one quote is significantly higher or lower than the others, don’t just dismiss it. Ask the manufacturer to explain their pricing. A low-cost provider might be using a lower-grade material or skipping a quality check. A high-cost provider might be including detailed inspection reports or using a more precise machine. Their answer will reveal a great deal about their process, trasparenza, and the true value they offer.

The Value of Premium Partners

A slightly higher price from a premium partner can often result in a lower total project cost. This is because they help you avoid the expensive pitfalls of product development. By providing expert DFM feedback, guaranteeing material quality, and delivering a dimensionally accurate part on time, they prevent costly redesigns, material failures, and missed market opportunities. The investment in a quality-focused partner is an investment in risk reduction and project success. It is about maximizing your return on investment, not just minimizing the initial cost.

Successful Partnership Case Studies

The principles of selecting a manufacturer are best understood through real-world examples. These case studies, based on common project journeys, show how the right partnership can overcome challenges and lead to successful outcomes. They demonstrate the real value of expertise, communication, and a strategic approach to prototyping.

Caso di studio: Startup Prototype

- The Challenge: A hardware startup with a limited budget and an aggressive timeline needed a prototype of their new smart home device. The prototype had to be both visually appealing for investor presentations and functional enough for basic user testing. The deadline was less than three weeks away to secure a spot in a pitch competition.

- The Manufacturer Solution: The chosen rapid prototype manufacturer reviewed the design and proposed a hybrid manufacturing approach to balance cost, aspetto, and function. They used SLA for the external housing to achieve a smooth, injection mold-like surface finish. For a critical internal bracket that required high strength and precision, they used CNC machining in aluminum. Crucially, their DFM feedback identified that a slight change to the enclosure’s snap-fit design would make assembly much faster, reducing the final labor cost.

- The Outcome: The startup received a fully assembled, high-quality prototype two days ahead of schedule. The professional finish and robust feel of the device greatly impressed investors, contributing directly to a successful seed funding round. *Takeaway: A smart partner optimizes the entire process, not just the fabrication of individual parts.*

Caso di studio: Engineer’s Functional Test

- The Challenge: An automotive engineer was developing a new air intake manifold for a high-performance engine. Before committing to expensive production tooling, she needed to create a functional prototype to test for airflow dynamics and durability under real-world heat and pressure conditions. The material properties of the prototype had to be as close to the production-grade, glass-filled polymer as possible.

- The Manufacturer Solution: After an initial consultation, the partner, an expert in engineering-grade materials, recommended against a standard nylon. Invece, they suggested using SLS with a specialized glass-filled nylon powder (PA-GF), known for its exceptional stiffness and high heat deflection temperature. They provided the engineer with a full material datasheet to compare against her production material specs and guaranteed that a Certificate of Conformity would be shipped with the finished part, verifying the material used.

- The Outcome: The prototype manifold was delivered with all required documentation. It successfully withstood the rigorous testing protocol, including multiple heat and pressure cycles, validating the engineer’s design. The detailed material certification provided the engineering team with the confidence they needed to sign off on their test results and proceed to the tooling phase, saving tens of thousands of dollars by avoiding a potential design flaw. *Takeaway: True expertise in materials is a critical differentiator for creating meaningful functional prototypes.*