A cosa presti attenzione quando si smalti con la lavorazione del CNC? Una guida completa

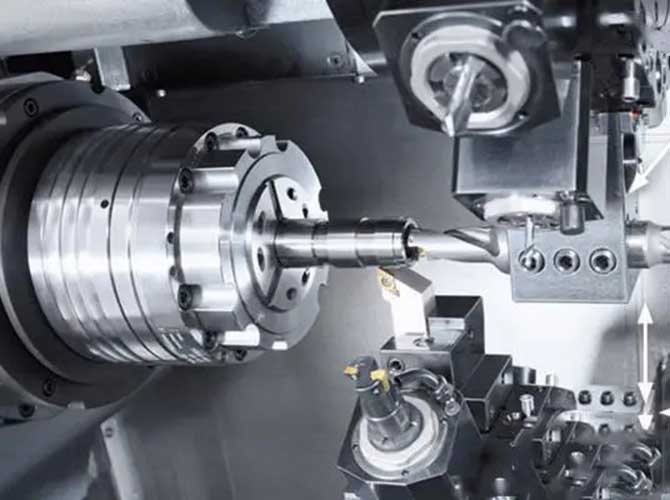

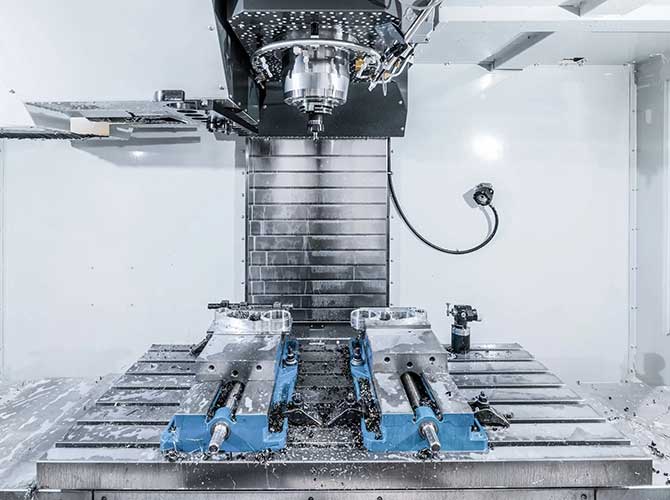

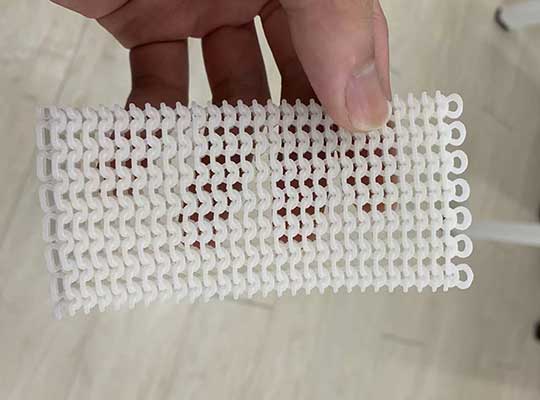

Chamfering is a critical yet often overlooked process in CNC machining that transforms sharp edges into controlled angled surfaces. While it may seem like a minor detail, proper chamfering significantly impacts part functionality, safety, assembly efficiency, and overall quality. This comprehensive guide explores the essential considerations for successful CNC machining chamfering, providing engineers and manufacturers […]