Perché la progettazione del taglio laser CNC è una competenza fondamentale nell'industria?

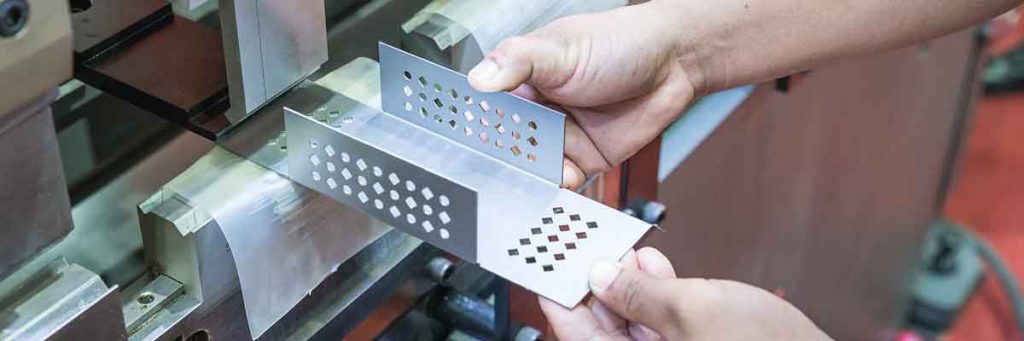

In vari campi come la produzione industriale, progettazione artistica, e lavorazione di ricambi auto, Il taglio laser CNC è diventato il metodo di lavorazione tradizionale con i suoi vantaggi di alta precisione ed efficienza. Tuttavia, molti utenti incontreranno problemi come “taglio incompleto”, “sbavature sui bordi”, E “errori di importazione dei file” nel funzionamento effettivo, e il motivo principale […]