L'illuminazione non è solo questione di luminosità, ma anche di abbinamento al tuo stile, spazio, e bisogni. Ma le lampade tradizionali spesso non sono all’altezza: forme generiche, tempi di consegna lunghi, e personalizzazione limitata. Ecco dove 3D printing lamps come in. Questa tecnologia risolve i principali punti critici sia dei proprietari di case che dei progettisti, offrendo design unici, produzione veloce, e funzionalità intelligenti. Let’s explore why 3D printing is revolutionizing the lighting industry.

1. Unmatched Design Flexibility: From Art to Everyday

The biggest advantage of 3D printing lamps is their ability to break free from traditional manufacturing limits. Designers can turn bold ideas into reality, and users can get lamps that fit their space perfectly.

Key Design Benefits of 3D Printing Lamps

| Design Feature | Details | Example Use Case |

| Complex Shapes | Creates intricate patterns (per esempio., leaf veins, geometric lattices) that injection molding can’t make | A pendant lamp shaped like a blooming lotus—light filters through lattice gaps for a soft, nature-inspired glow |

| Natural Element Mimicry | Replicates organic forms (branches, petals, conchiglie) with precise detail | A table lamp with a base that looks like twisted driftwood |

| Personalization | Customizes size, colore, and pattern to match home decor | A bedroom lamp in your favorite color (per esempio., sage green) with your initials engraved |

Esempio del mondo reale: Abstract Art Lamps

A interior designer needed a lamp for a modern living room with curved walls. Traditional lamps were too boxy—so they used 3Stampa D:

- Designed a curved, wave-shaped lampshade in CAD software.

- Printed it in matte white PLA (a eco-friendly plastic).

- Added an LED bulb that changes color.

Il risultato? A lamp that hugs the wall, matches the room’s curves, and becomes a conversation piece.

2. Fast Production: From Design to Delivery in Days

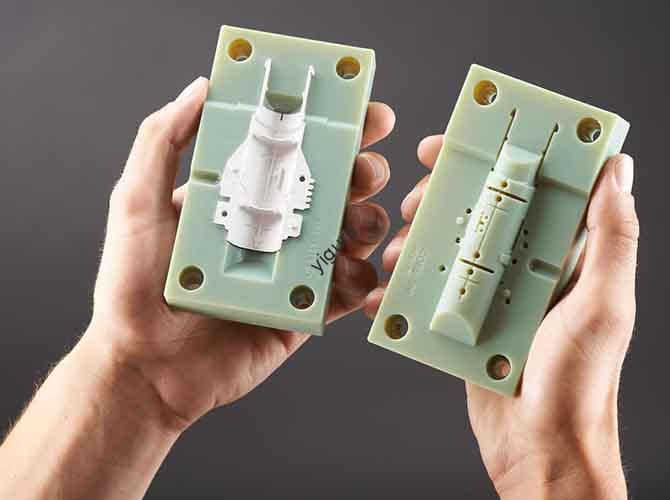

Traditional lamp production can take weeks (realizzazione di stampi + assemblaggio). 3D printing lamps slash lead times, making it easy to get custom or replacement lamps quickly.

Production Speed Comparison: 3D Stampa vs. Traditional Lamps

| Stage | 3D Lampade di stampa | Traditional Lamps |

| Prototyping Time | 1–2 days (print a sample from a CAD file) | 2–3 weeks (create a mold first) |

| Custom Order Delivery | 3–5 giorni (progetto + print + assemble) | 4–6 weeks (mold adjustments + produzione) |

| Design Changes | Update CAD file in 1 hour (no new tools) | 1–2 weeks (new mold or tooling) |

How It Solves Urgent Needs

Imagine you’re hosting a party in 10 days and need a new table lamp for your dining area. With 3D printing lamps:

- Choose a design from an online library (or upload your own).

- Select color (per esempio., warm brass-effect PLA) and size.

- Receive the lamp in 4 days—no waiting for weeks.

3. Diverse Material Options: Balance Style, Durabilità, and Cost

3D printing lamps work with a range of materials, each offering unique benefits. You can pick the right material for your needs—whether you want something cheap, durevole, or luxurious.

Common Materials for 3D Printing Lamps

| Tipo materiale | Vantaggi principali | Ideale per |

| PLA (Acido Polilattico) | Eco-friendly (made from corn starch), basso costo, easy to print | Everyday lamps (bedroom, home office); entra 50+ colors |

| ABS (Acrilonitrile Butadiene Stirene) | Durable, resistente al calore (safe for LED bulbs), scratch-proof | Lamps in high-traffic areas (hallways, kids’ rooms) |

| Photosensitive Resin | Smooth surface, high detail (like glass), translucent | Luxury lamps (living room pendants); light shines through evenly |

| Metal (Acciaio inossidabile, Alluminio) | Premium look, heavy-duty, long-lasting | Statement lamps (entryway, hotel lobbies); adds a modern, industrial vibe |

Pro Tip: Composite Materials for Extra Style

For a unique look, mix materials:

- Wood + PLA: A lamp base that looks like real wood (affordable and lightweight).

- Plastic + Metal: A lampshade with plastic lattice and metal accents (durable and stylish).

4. Smart and Eco-Friendly Features: Beyond Basic Lighting

3D printing lamps aren’t just about looks—they also offer functional upgrades that save energy and make life easier.

Functional Advantages of 3D Printing Lamps

| Feature | Come funziona | Benefit for Users |

| Intelligent Control | Connects to phone apps or voice assistants (Alexa, Google Home) to adjust brightness, colore, and timer | Turn the lamp on/off from your bed; set a “bedtime mode” that dims slowly |

| Energy Efficiency | Uses LED bulbs (standard with most 3D printed lamps) + precise material use (no waste) | Cuts energy bills by 75% contro. incandescent bulbs; reduces environmental impact |

| Space-Saving Designs | Prints compact, multi-purpose lamps (per esempio., a lamp with a built-in phone holder) | Saves space on nightstands or desks |

Esempio: Smart Bedroom Lamp

A 3D printed lamp with:

- App control: Adjust brightness from 10% (soft night light) A 100% (reading light).

- Color change: Switch from warm white (relaxing) to cool white (focused) for work.

- Timer: Turns off automatically after 30 minutes (great for kids’ bedrooms).

5. Artistic and Collectible Value: Lighting as Art

3D printing lamps aren’t just functional—they’re works of art. Limited-edition designs or custom pieces often become collectibles, loved by design enthusiasts.

Why 3D Printing Lamps Have Artistic Value

- One-of-a-Kind Pieces: Many 3D printed lamps are made in small batches (or even one-off) by independent designers.

- Tech-Meets-Art: Combines modern 3D printing tech with traditional art (sculpture, pattern design).

- Storytelling: A lamp’s design can tell a story—e.g., a lamp shaped like a constellation for an astronomy fan.

Collectible Example: Limited-Edition Geometric Lamps

A designer released 50 3D printed lamps with unique geometric patterns (each slightly different). They sold out in 3 days because:

- Each lamp was numbered (per esempio., “1/50”).

- The design was inspired by mid-century modern art.

- The material (photosensitive resin) gave it a glass-like, luxury finish.

La prospettiva della tecnologia Yigu

Alla tecnologia Yigu, crediamo 3D printing lamps are the future of lighting. We’ve tested 200+ lamp designs with PLA, resina, e materiali compositi, and found that 3D printing cuts production time by 80% contro. traditional methods. We’re now developing smart 3D printed lamps with sensors that adjust brightness based on natural light—saving even more energy. For homeowners, this means affordable, custom lighting; for designers, it means unlimited creativity. We’re excited to make 3D printing lamps accessible to everyone in 2025.

Domande frequenti

- Q: Are 3D printing lamps safe to use with LED bulbs?

UN: SÌ! Most 3D printing materials (PLA, ABS, resina) are heat-resistant enough for LED bulbs (which stay cool). Just avoid using high-wattage incandescent bulbs (they get too hot).

- Q: How much do 3D printing lamps cost compared to traditional lamps?

UN: Basic 3D printed lamps start at \(30 (similar to traditional budget lamps). Custom or premium designs (metallo, resina) costo \)80–$200—worth it for unique style and fast delivery.

- Q: Can I recycle old 3D printed lamps?

UN: SÌ! PLA lamps are 100% biodegradable. ABS and resin lamps can be melted down and reused for new 3D prints. Just check with local recycling centers for proper disposal.