3D printing service for prototype Custom

As one of the leading manufacturers of fast 3D printing, Yigu provides you with one-stop 3D printing and production solutions aimed at helping designers and engineers create excellent products faster and more economically. We enable them to quickly create and test physical model prototypes.

Our 3D printing services

Yigu is an expert in the field of prototype manufacturing in China. We provide a wide range of 3D printing services, including SLA 3D printing (stereolitografia) and SLS 3D printing (sinterizzazione laser selettiva) options, Fusione laser selettiva (SLM), Elaborazione digitale della luce (DLP), PolyJet 3D Printing.

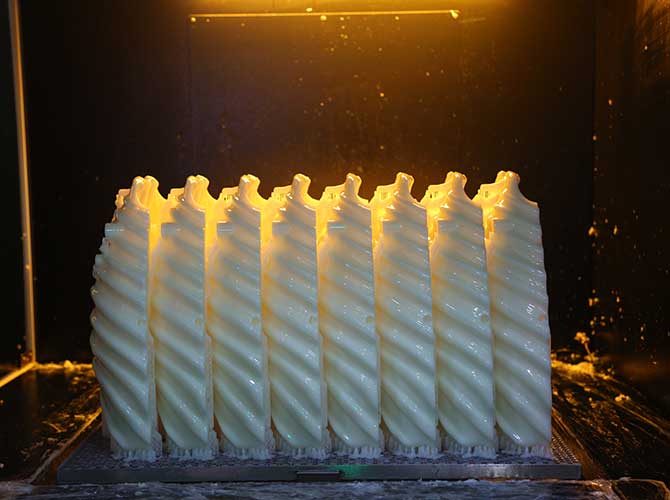

SLS

laser sintering

Functional prototype, durable parts with complex geometric shapes.

⦁ The maximum molding size can reach 600 * 450 * 350mm

⦁ The fastest is 2 giorni

⦁ Dimensional accuracy ± 0.3%, with a lower limit of ± 0.3 mm (± 0.012 “)

⦁ Layer thickness of 80 µm

SLA stereolithography

Appearance prototype, comparable to injection molded parts.

⦁ The maximum construction size can reach 1370 * 670 * 498 mm

⦁ The fastest one day

⦁ Dimensional accuracy ± 0.5%, lower limit ± 0.15 millimetri

⦁ Floor height 50-100 µm

FDM

fused deposition molding

Affordable and easy to use

⦁The maximum construction size can reach 1380 × 680 × 480 millimetri

⦁The fastest one day

⦁Dimensional accuracy ± 0.5%, lower limit ± 0.15 millimetri

⦁Floor height 50-100 µm

mjf

Fusione multigetto

High quality, functional components, exquisite details. A popular choice for small-scale production.

⦁ The maximum construction size is 600 x650 x 380 millimetri (14.9“x 11.2” x 14.9“)

⦁ Standard delivery time of 2 giorni

⦁ Dimensional accuracy ± 0.3%, with a lower limit of ± 0.3 mm (0.012“) layer

⦁ Thickness 80 microns

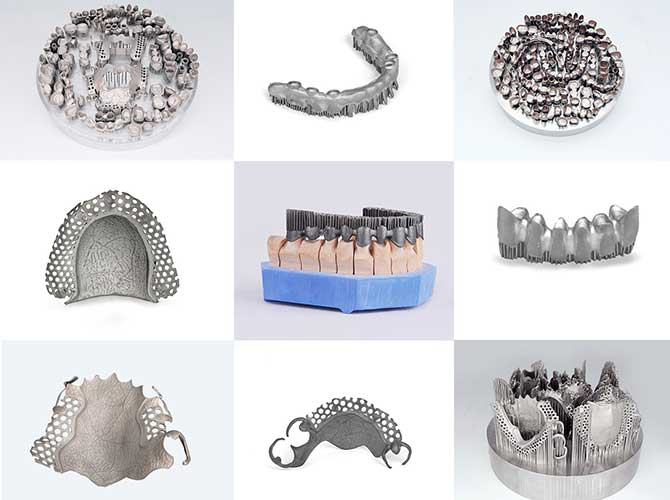

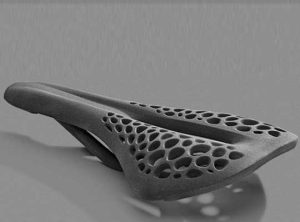

DMLS

3D Metal Laser Sintering

Material SS316L, Alsi 10Mg, Ti64 available for selection

⦁ Maximum construction size 280 * 280 * 350 millimetri

⦁ Standard delivery time of 7 working days

⦁ Dimensional accuracy ± 0.2%, lower limit ± 0.2 millimetri

⦁ The floor height is 30 µm

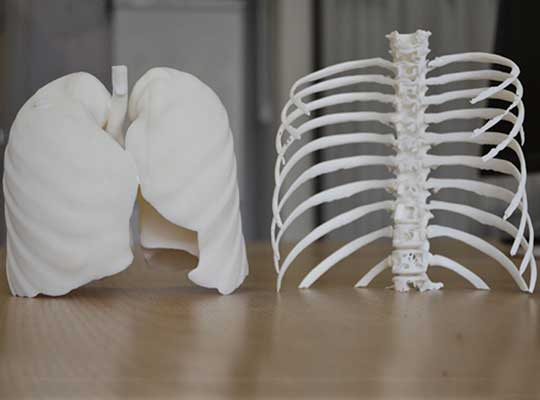

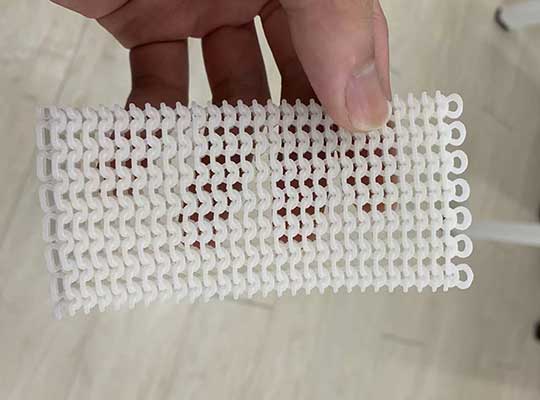

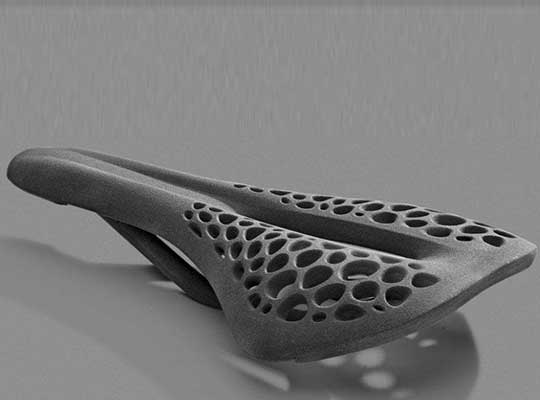

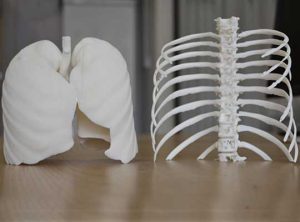

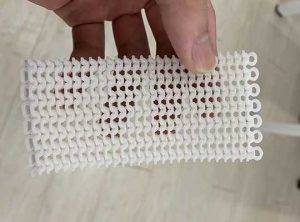

Additive Manufacturing Prototype and Parts Display

The products displayed below have been approved by the customer, and we strictly abide by the confidentiality agreement to protect the customer’s confidentiality and creativity.

Material selection for 3D printing

Difference between SLS and SLA 3D Printing

SLA 3D printing technology features:

- High precision stereolithography molding: capable of producing parts with complex structures.

- Quickly complete the prototype: It can greatly shorten the development cycle.

SLS 3D printing technology features:

- Excellent mechanical performance, capable of functional testing and small-scale production.

- Prototype materials are diverse.

- Can produce products with any complex structure.

Why choose our 3D printing service?

At Yigu, we offer a variety of manufacturing solutions, from 3D printed prototypes to small batch production.

We are supported by ISO 9001:2015 certification and have over 190 senior technical experts as well as various 3D printers such as SLS, SLA, mjf, e FDM.

Based on your specific requirements and product structure, we can provide you with suitable 3D printing methods

Including SLA 3D printing (stereolitografia), SLS 3D printing (sinterizzazione laser selettiva), mjf (multi jet fusion), and DMLS (sinterizzazione laser diretta dei metalli).

These methods can be used for sample production and small batch production in the product development process.

Based on the production scale and standards of the project, we can complete production within 2 A 10 giorni.

We have strong production capabilities and can flexibly arrange production cycles to meet your various product production needs.

The advantages of 3D printing

Velocità: 3D printing prototype production allows designers and engineers to quickly create physical prototypes, thereby accelerating the design and development process.

Cost effectiveness: 3D printing prototype production is cheaper than traditional prototyping methods such as CNC machining, injection molding, or casting.

Flexibility: 3D printing can create complex geometric shapes that traditional manufacturing techniques cannot achieve.

Iterazione: 3D printing prototyping allows designers and engineers to quickly iterate and refine their designs based on feedback from stakeholders and users.

3D Printing Applications

Industria: 3D printing is used for manufacturing lightweight, componenti complessi, as well as for manufacturing replacement parts and tools.

Automobiles: 3D printing is used to create prototypes, stampi, and even functional automotive parts such as engine components, exhaust systems, and interiors.

Consumer products: 3D printing is used to create customized or small batch products, such as jewelry, phone cases, and other accessories.

Industrial manufacturing: 3D printing is used for small-scale production of fixtures and fixtures, utensili, and parts for a range of industries.

3D printing’s applications are vast, spanning heavy industry like Aerospace E Automobilistico, and transforming healthcare through Medico E Dental usi. It drives innovation in Elettronica E Tooling, while also enabling creativity in toy, Jewelry, Art, Fashion, e persino Food. It is also a vital tool for Prototyping, Education, E Architecture.