Hai mai passato ore a progettare un modello 3D, solo per scoprire che non verrà stampato o che la parte finita è deformata, rotto, o dettagli mancanti? 3D printed modeling is the make-or-break step in 3D printing: non si tratta solo di creare una forma digitale, ma progettarne uno che funzioni con le capacità della tua stampante. This guide breaks down everything you need to know—from choosing the right modeling method to fixing common design flaws—so you can turn your ideas into successful 3D prints.

1. What Is 3D Printed Modeling?

3D printed modeling is the process of creating or modifying 3D digital models specifically optimized for 3D printing. Unlike general 3D modeling (which might focus only on visual appeal), it requires thinking about how the model will be costruito strato dopo strato.

Think of it like designing a house: a regular architect might focus on how it looks, but a 3D print modeler is like a builder who also plans where the support beams go, how the walls will stand, and if the roof can be built without collapsing. Per esempio, a 3D model of a cup might look great digitally—but if its walls are too thin (under 1mm), it will crack during printing.

2. 2 Core 3D Printed Modeling Methods: Which to Choose?

There are two main ways to create 3D models for printing, each with pros, contro, and best-use cases. The table below helps you pick the right one for your project:

| Method | Come funziona | Ideale per | Pro | Contro |

| Manual Modeling | Use professional 3D software to build models from scratch—you control every detail, from shapes to dimensions. | Custom designs (per esempio., a unique phone case, a personalized figurine) or parts with specific tolerances (per esempio., a replacement gear). | – Full control over design; – Creates highly precise, printable models; – Ideal for one-of-a-kind projects. | – Requires design skills (1–3 months of practice for beginners); – Takes longer (per esempio., 4–8 hours for a detailed figurine). |

| Scan Modeling | Use a 3D scanner to capture the shape of an existing object (per esempio., a toy car, a hand) and convert it into a digital model. | Replicating real-world items (per esempio., a broken part you need to replace) or capturing organic shapes (per esempio., a custom mask for cosplay). | – Fast (10–30 minutes per scan); – No design skills needed; – Perfect for matching real objects exactly. | – Scanners can be expensive (\(100–)10,000); – Scanned models often need repair (per esempio., filling holes, fixing uneven surfaces). |

3. Top 3D Printed Modeling Software: For Beginners to Pros

The right software makes 3D printed modeling easier—whether you’re new to design or a professional. Below are the most popular options, organized by skill level:

For Beginners (No Design Experience)

- Tinkercad: A free, browser-based tool with simple drag-and-drop features. Great for basic shapes (per esempio., a box, a custom keychain). You can combine pre-made “blocks” to build models—no need to draw from scratch.

- SketchUp Make: Free for personal use, with a user-friendly interface. Ideal for designing furniture, toys, or simple mechanical parts. It has a large library of pre-made models (per esempio., wheels, hinges) to speed up your work.

For Intermediate Users (Some Design Skills)

- Blender: A free, open-source tool with powerful features. Perfect for detailed models (per esempio., figurine, props) and organic shapes (per esempio., animal statues). It also has built-in tools to check if your model is printable (per esempio., fixing non-manifold geometry).

- Fusion 360: A subscription-based tool ($60/year for hobbyists) that’s great for functional parts (per esempio., brackets, ingranaggi). It combines 3D modeling with engineering tools—you can test if a part will withstand weight or pressure before printing.

For Professionals (Advanced Design Needs)

- SolidWorks: The industry standard for mechanical design. Used by engineers to create high-precision parts (per esempio., dispositivi medici, componenti aerospaziali). It has strict tolerance controls—critical for parts that need to fit together perfectly.

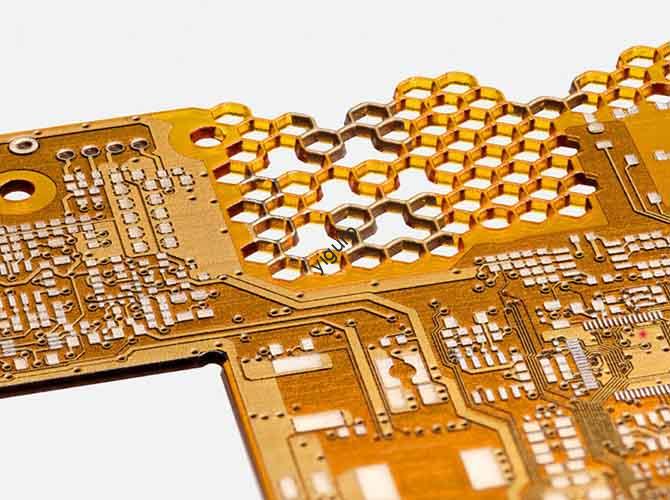

- AutoCAD: Widely used in construction, macchinari, ed elettronica. Ideal for complex models with precise dimensions (per esempio., a 3D-printed circuit board housing). It exports to all major 3D printing file formats (STL, OBJ, 3MF).

4. 5 Critical 3D Printed Modeling Tips to Avoid Print Failures

Even the best software won’t save a poorly designed model. Follow these tips to ensure your model is printable and high-quality:

- Check Wall Thickness: The walls of your model need to be thick enough to support themselves. For PLA (the most common material), use a minimum wall thickness of 1.2–2mm. For ABS or resin, go thicker (1.5–2.5mm). If walls are too thin, the part will crack during printing—like a paper cup trying to hold water.

Esempio: A 3D-printed PLA spoon with 0.8mm walls broke on first use. Redesigning it with 1.5mm walls made it strong enough to stir coffee.

- Add Support Structures for Overhangs: Any part of your model that hangs over 45° (per esempio., a figurine’s outstretched arm, a cup’s handle) needs supports. Senza di loro, the printer will print “in mid-air”—the plastic will sag or fall. Most software lets you add supports automatically (choose “tree supports” to save material).

- Avoid Sharp Corners: Sharp corners trap stress and can cause warping. Replace them with rounded edges (called “fillets”)—a 1–2mm fillet is enough. Per esempio, a 3D-printed box with sharp corners warped during cooling; adding 2mm fillets made it flat and stable.

- Optimize for Your Printer’s Build Volume: Measure your printer’s maximum print size (per esempio., 220x220x250mm for a Creality Ender 3) and design your model to fit. If your model is too big, split it into smaller parts (use software like Meshmixer to cut it) and glue them together after printing.

- Test for Printability: Use software tools to check for common issues:

- Non-manifold geometry: Parts of the model that aren’t connected (per esempio., a hole that goes all the way through but isn’t closed). Blender’s “3D Print Toolbox” fixes this with one click.

- Overlapping faces: Two parts of the model that occupy the same space. Fusion 360’s “Inspect” tool highlights these so you can delete or move one.

5. Model Repair & Ottimizzazione: Fixing Flaws Before Printing

Even well-designed models need tweaks to be perfect. Follow this linear workflow to repair and optimize your model:

- Fill Holes: Use your software’s “fill” tool to close small holes (under 5mm). For larger holes, add a patch of material—holes let air in during printing and can cause layers to separate.

- Reduce Triangle Count: STL files use triangles to build the model. Too many triangles (Sopra 1 milioni) slow down slicing and printing. Use “decimation” tools (in Blender or Meshmixer) to reduce the count by 30–50% without losing detail.

- Adjust Scale: Make sure your model is the right size for your needs. Per esempio, if you’re printing a replacement button for a remote control, measure the original button (per esempio., 10mm wide) and scale your model to match. Most software has a “scale” tool that lets you enter exact dimensions.

- Export to the Right File Format: Use STL for most printers—it’s the most widely supported. For models with color or texture, use 3MF (it preserves more details). Avoid OBJ unless your printer specifically requires it (it can lose some geometry during export).

6. Slicing: The Final Step Before Printing

Slicing is where you turn your 3D model into instructions the printer can follow. Here’s how to do it right:

- Choose Slicing Software: Use Cura (free, works with most printers) or PrusaSlicer (great for Prusa printers). Import your STL/3MF file.

- Set Material-Specific Settings: For PLA, use these settings:

- Altezza dello strato: 0.15–0.2mm (balances speed and detail).

- Riempimento: 20–30% (enough strength for decorative parts; utilizzo 50% for functional parts).

- Print speed: 40–60mm/s.

- Preview the Slice: Most software lets you preview the model layer by layer. Check for issues:

- Are supports covering critical details (per esempio., a figurine’s face)? If yes, adjust support placement.

- Is the first layer sticking to the bed? Make sure the bed temperature is set to 50–60°C for PLA.

- Export G-Code: Save the sliced file as G-code (the language printers understand) and transfer it to your printer via USB or SD card.

7. Yigu Technology’s Perspective on 3D Printed Modeling

Alla tecnologia Yigu, we see 3D printed modeling as the foundation of successful 3D printing. The biggest mistake we see? Designers focusing only on looks, not printability—we’ve fixed hundreds of models with thin walls or missing supports that would have failed.

Our pro tip: For clients designing functional parts (per esempio., automotive prototypes), we use SolidWorks to test models for stress and printability before production. We also offer a free “Model Check” service—upload your model, and we’ll flag issues like thin walls or overhangs in 24 ore. As 3D printing materials evolve (per esempio., flexible TPU), we’re updating our modeling guides to help clients design parts that work with these new materials—ensuring every print is a success.

Domande frequenti: Your Top 3D Printed Modeling Questions Answered

Q1: I’m a beginner—what’s the easiest way to start 3D printed modeling?

A1: Start with Tinkercad (free, browser-based) and simple projects: a keychain, a small box, or a coaster. Use pre-made shapes to build your model—you’ll learn the basics in a few hours. Once you’re comfortable, move to Blender for more detailed designs.

Q2: My scanned model has holes—how do I fix them?

A2: Use Meshmixer (free) to fill holes: Import your model, go to “Edit” > “Fill Holes.” For small holes, the software will fill them automatically. For large holes, use the “Bridge” tool to connect the edges of the hole with new geometry.

Q3: Can I design a 3D printed model that moves (per esempio., a hinge or a gear)?

A3: SÌ! Use Fusion 360 or SolidWorks to design moving parts. Leave a small gap (0.2–0.3mm) between parts (per esempio., between a hinge pin and the hinge) so they can move freely. Test the model digitally first—most software lets you simulate movement to make sure parts don’t get stuck.