Our Inconel 3D Printing Services

Unlock the future of high-performance manufacturing with Inconel 3D Printing—the cutting-edge fusion of Nickel-based Alloy strength and Additive Manufacturing flexibility. Whether you need custom aerospace components, durable industrial parts, or precision medical devices, our expertise delivers high-quality, tailor-made solutions that outperform traditional methods. Experience faster production, superior material properties, and unmatched accuracy—your trusted partner for all Inconel 3D Printing needs.

What Is Inconel 3D Printing?

At its core, Inconel 3D Printing combines two game-changing technologies: Inconel and 3D Printing (also known as Additive Manufacturing). Inconel refers to a family of super-strong Nickel-based Alloy materials, famous for resisting extreme heat, corrosion, and pressure—making them ideal for harsh environments like jet engines or chemical plants. 3D Printing, on the other hand, is an additive process that builds parts layer by layer from digital designs, unlike traditional subtractive methods that cut away material.

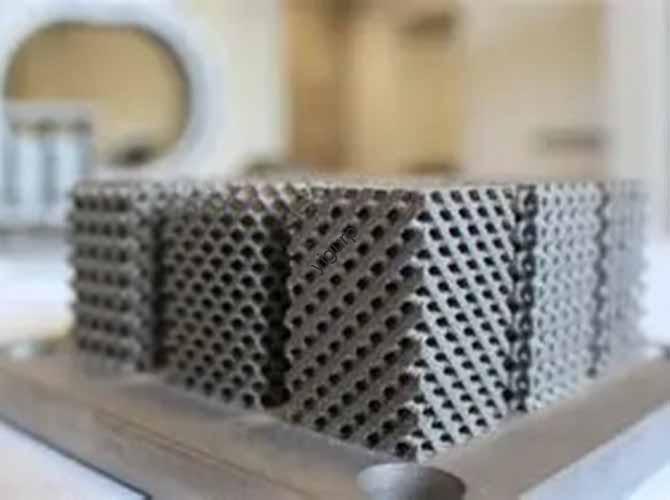

Together, Inconel 3D Printing creates complex, high-performance parts without the limitations of conventional manufacturing. This technology eliminates the need for expensive molds, reduces material waste, and enables designs that were once impossible—from intricate internal channels to lightweight, strength-optimized structures. Simply put, the Definition of Inconel 3D Printing is the future of manufacturing for industries that demand reliability and innovation.

Our Capabilities: Delivering Excellence in Inconel 3D Printing

When you choose our services, you gain access to a suite of capabilities designed to meet your most demanding needs. Our team brings deep Inconel Printing Expertise—honed through years of working with aerospace, automotive, and medical clients—to every project. We use Advanced 3D Printing Technology, including state-of-the-art laser powder bed fusion (LPBF) and directed energy deposition (DED) systems, to ensure consistent quality.

We specialize in Custom Inconel Solutions: whether you need a one-of-a-kind prototype or high-volume production runs, we tailor our process to your design specs, material preferences, and performance requirements. The result? High-Quality Inconel Parts that meet or exceed industry standards for strength, durability, and precision. Below is a snapshot of our key Capabilities in Inconel 3D Printing:

| Capability | Key Features | Industry Applications |

| Custom Design Support | CAD optimization, topology analysis, rapid prototyping | Aerospace, Medical, Automotive |

| High-Volume Production | Automated systems, consistent batch quality, fast turnaround | Industrial, Automotive |

| Material Expertise | Sourcing and testing of premium Inconel alloys (e.g., 625, 718) | Aerospace, Chemical Processing |

| Quality Control | Post-print inspection, non-destructive testing (NDT), certification | All industries (especially aerospace/medical) |

Process: Step-by-Step Guide to Inconel 3D Printing

The Inconel 3D Printing Process is a precise, multi-stage workflow that ensures every part meets strict standards. While it aligns with the broader Additive Manufacturing Process, it includes specialized steps to handle the unique properties of Inconel (like its high melting point). Below is a clear, Step-by-Step Inconel Printing breakdown, also known as the Inconel Printing Procedure:

- Design & Preparation: First, we create or refine a 3D CAD model of the part. We optimize the design for 3D printing—adding support structures (to prevent warping) and adjusting layer heights for precision.

- Material Setup: We load high-quality Inconel Powders into the 3D printer. The powder is carefully dried and sifted to remove clumps, ensuring smooth layer deposition.

- Printing: The printer uses a high-power laser (for LPBF) to melt the Inconel powder layer by layer, following the CAD design. The build chamber is kept in a controlled atmosphere (usually argon) to prevent oxidation.

- Post-Print Removal: Once printing is complete, the part is removed from the build plate. Support structures are cut or dissolved away.

Heat Treatment: The part undergoes heat treatment (like annealing or solution aging) to reduce internal stresses and enhance mechanical properties—critical for Inconel’s strength.

Materials: Choosing the Right Inconel for Your Project

Inconel Alloys are the backbone of our 3D printing process, and selecting the right material is key to project success. Unlike generic 3D Printing Materials, Inconel offers unique advantages: exceptional heat resistance (up to 1,200°C for some alloys), corrosion resistance, and high tensile strength. All our Nickel-based Materials are certified to meet industry standards (e.g., ASTM, AMS) for consistency and performance.

Below is a comparison of the most common Materials for Inconel 3D Printing we use:

| Inconel Alloy | Key Properties | Typical Applications |

| Inconel 625 | Excellent corrosion resistance, high strength at high temperatures | Chemical processing equipment, aerospace engine components |

| Inconel 718 | High fatigue resistance, easy to machine post-print | Gas turbine parts, automotive turbochargers, medical implants |

| Inconel X-750 | Superior creep resistance (resists deformation under long-term heat) | Aerospace fasteners, nuclear reactor components |

| Inconel 600 | Good oxidation resistance, low thermal expansion | Furnace parts, heat exchangers |

All our Inconel Powders have a tight particle size distribution (usually 15-45 μm) to ensure smooth printing and dense, high-quality parts.

Surface Treatment: Enhancing Inconel Part Performance

After 3D printing, Inconel Surface Finishing is essential to improve part functionality, appearance, and durability. Raw 3D-printed parts may have rough surfaces (from layer lines) or residual powder, which can affect performance—especially in applications like fluid flow or medical devices. Our Surface Treatment Techniques are tailored to Inconel’s unique properties, ensuring we don’t compromise the alloy’s strength or corrosion resistance.

Common Post-Processing for Inconel methods we offer include:

- Abrasive Blasting: Uses fine grit (like aluminum oxide) to remove residual powder and smooth surfaces. Creates a uniform, matte finish.

- CNC Machining: For parts that need tight tolerances (e.g., 0.001 mm), we use precision CNC machining to refine critical features.

- Electropolishing: A chemical process that removes a thin layer of material to create a smooth, shiny surface. Enhances corrosion resistance—ideal for medical or food-processing parts.

- Passivation: Treats the surface with a chemical solution (like nitric acid) to form a protective oxide layer, boosting corrosion resistance for harsh environments.

Our Surface Enhancement processes are validated to meet industry standards, and we work with you to choose the right treatment based on your part’s application.

Tolerances: Achieving Precision in Inconel 3D Printing

Precision is non-negotiable in industries like aerospace and medical—where even small deviations can cause failure. That’s why we prioritize Inconel Printing Tolerances that exceed industry benchmarks. Our Precision in Inconel 3D Printing is achieved through a combination of advanced technology, skilled operators, and rigorous quality control.

Typically, our Tolerance Levels for 3D-printed Inconel parts are:

- Dimensional tolerance: ±0.1 mm for parts up to 100 mm; ±0.1% for parts larger than 100 mm.

- Geometric tolerance: Compliant with ISO 8015 (geometric product specifications) for flatness, straightness, and circularity.

For applications that demand even higher accuracy—like medical implants or aerospace sensors—we offer secondary processes (like CNC machining) to achieve High-Accuracy Inconel Parts with tolerances as tight as ±0.005 mm. Our Tolerances for Inconel Additive Manufacturing are regularly tested and certified, so you can trust that every part meets your exact specs.

Advantages: Why Inconel 3D Printing Outperforms Traditional Methods

The Benefits of Inconel 3D Printing are clear: it solves the biggest challenges of traditional manufacturing (like casting or forging) while unlocking new possibilities. Here’s how it delivers Advantages in Manufacturing for your business:

- Design Freedom: Unlike casting, which requires simple geometries, 3D printing lets you create complex parts (e.g., internal cooling channels, lattice structures) without extra cost. This reduces part count—for example, a 5-part aerospace assembly can become 1 3D-printed part.

- Faster Time-to-Market: Prototyping with 3D printing takes weeks, not months. For production, it eliminates mold lead times (which can be 6+ months for traditional methods).

- Material Efficiency: Traditional subtractive methods waste up to 80% of Inconel (a costly material). 3D printing uses only the powder needed for the part, reducing waste to less than 5% (and unused powder is recyclable).

- Superior Properties: 3D-printed Inconel parts often have better mechanical properties than cast or forged parts. For example, 3D-printed Inconel 718 has a tensile strength of 1,400 MPa—20% higher than forged Inconel 718.

- Enhanced Performance: The layer-by-layer process creates dense parts (99.9% density for our Inconel prints) with uniform material properties, reducing the risk of defects like porosity.

These Inconel Printing Advantages translate to lower costs, better parts, and a competitive edge for your business.

Applications Industry: Where Inconel 3D Printing Shines

Applications Industry: Where Inconel 3D Printing Shines

Inconel 3D Printing Uses span across industries that demand high performance, durability, and precision. Its unique combination of strength and flexibility makes it a top choice for sectors where failure is not an option. Below are the key industries we serve:

- Aerospace Industry: The aerospace sector relies heavily on Inconel 3D Printing for engine components (like turbine blades and combustors), brackets, and fasteners. 3D printing reduces weight (critical for fuel efficiency) while withstanding the extreme heat of jet engines. For example, we’ve printed Inconel 718 turbine parts that weigh 30% less than traditional cast parts.

- Automotive Industry: In high-performance and electric vehicles (EVs), Inconel parts (like turbochargers and battery cooling systems) handle high temperatures and corrosion. 3D printing lets automakers quickly iterate designs and produce low-volume, custom parts for racing or luxury models.

- Medical Applications: Inconel’s biocompatibility (especially for Inconel 718) and corrosion resistance make it ideal for medical implants (like hip stems or dental abutments). 3D printing creates implants tailored to a patient’s anatomy, improving comfort and healing time.

Industrial Applications: For chemical plants, oil refineries, and power generation, Inconel parts (like valves, pumps, and heat exchangers) resist corrosion from harsh chemicals and high pressure. 3D printing reduces downtime by enabling fast replacement of hard-to-source parts.

Manufacturing Techniques: The Methods Behind Our Inconel 3D Printing

Our Inconel Manufacturing Methods combine the best of Additive Manufacturing Techniques with specialized processes for Nickel-based Alloys. We focus on two primary 3D Printing Techniques for Inconel, each suited to different part sizes and requirements:

- Laser Powder Bed Fusion (LPBF): This is our go-to method for small to medium-sized, high-precision parts (e.g., medical implants, aerospace sensors). It uses a focused laser to melt Inconel powder in a thin layer (20-50 μm) on a build plate. LPBF delivers exceptional detail and density (99.9% for Inconel), making it ideal for parts with tight tolerances.

- Directed Energy Deposition (DED): For larger parts (e.g., industrial valves, aerospace engine casings) or repairs (like fixing worn turbine blades), DED is the best choice. It uses a laser or electron beam to melt Inconel powder as it’s fed through a nozzle, building parts layer by layer. DED is faster for large volumes and can add material to existing parts (a process called “cladding”).

Both Inconel Production Techniques are supported by our quality control system, which includes real-time monitoring of the printing process (to catch defects early) and post-print testing (like tensile strength and corrosion resistance tests). Our Manufacturing with Inconel is designed to be scalable—whether you need 1 part or 1,000.

Case Studies: Real-World Success with Inconel 3D Printing

Our Inconel 3D Printing Case Studies show how we’ve helped clients solve complex manufacturing challenges. Below are two Real-World Applications that highlight our expertise:

Case Study 1: Aerospace Engine Component

Client: A leading aerospace manufacturer.

Challenge: They needed a lightweight, high-strength turbine combustor that could withstand 1,100°C. Traditional casting required 6 months of lead time and produced parts with 15% weight waste.

Solution: We used LPBF to 3D print the combustor from Inconel 625. We optimized the design with internal cooling channels (impossible with casting) to reduce weight by 25%.

Result: The part met all performance specs (tensile strength of 1,200 MPa, corrosion resistance to jet fuel), lead time was cut to 6 weeks, and material waste dropped to 5%. The client now uses our service for all their turbine combustor production.

Case Study 2: Medical Implant

Client: A medical device company.

Challenge: They needed custom hip stems for patients with unique anatomy. Traditional machining required 4 weeks per implant and often needed adjustments post-surgery.

Solution: We used LPBF to print hip stems from Inconel 718 (biocompatible and corrosion-resistant). We used the patient’s CT scan to create a 3D model, ensuring a perfect fit.

Result: Implants were produced in 1 week, and post-surgery adjustments dropped by 90%. Patients reported faster healing times, and the company expanded their product line with our support.

These Success Stories are just a few examples of how Case Studies in Inconel Printing demonstrate our ability to deliver results.

Why Choose Us: Your Trusted Partner for Inconel 3D Printing

When it comes to Inconel 3D Printing, we stand out for three key reasons:

- Unique Inconel Solutions: We don’t offer one-size-fits-all services. Our team works with you to understand your design, application, and budget, then creates a custom plan—whether it’s optimizing your CAD model, selecting the right Inconel Alloy, or choosing a surface treatment.

- Expertise in Inconel 3D Printing: Our engineers have an average of 8 years of experience with Nickel-based Alloys and 3D printing. We’re certified by industry bodies (e.g., AS9100 for aerospace, ISO 13485 for medical) and stay updated on the latest technology (like new Inconel Powders or printing techniques).

- Quality and Reliability: Every part we print undergoes rigorous testing—from material certification (to ensure it’s genuine Inconel) to post-print inspection (using X-rays, CT scans, and tensile tests). We guarantee that parts meet your specs, and we offer warranties on all our work.

Our commitment to Customer Satisfaction is clear: 95% of our clients return for future projects, and we’ve never missed a delivery deadline. These are the Reasons to Choose Our Inconel Printing—we’re not just a supplier, we’re your partner in innovation.