Le moulage sous pression en alliage d'aluminium est largement utilisé dans des industries comme l'automobile, aérospatial, et électronique, mais les pièces moulées brutes ne répondent souvent pas aux exigences de performance strictes. Aluminum alloy die casting heat treatment solves this by precisely controlling heating and cooling processes to optimize material properties. Cet article détaille ses objectifs principaux, méthodes, considérations clés, and practical applications to help you master this critical manufacturing step.

1. What Are the Core Purposes of Aluminum Alloy Die Casting Heat Treatment?

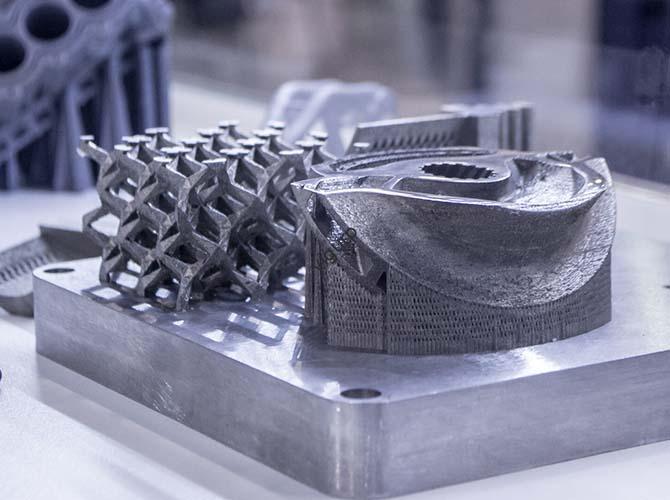

The primary goal of heat treatment is to address inherent flaws in raw castings and enhance their functionality. Below are the four key objectives, organized by priority:

| But | Avantage clé | Target Scenario |

| Eliminate internal stresses | Reduces cracking risk during machining or use | Castings with uneven wall thickness (par ex., supports de moteur) |

| Improve mechanical properties | Boosts tensile strength (par 20-40%), dureté, and plasticity | High-load parts (par ex., carters de transmission) |

| Stabilize structure & taille | Prevents volume changes from high-temperature phase transitions | Precision components (par ex., electronic sensor casings) |

| Optimize machining performance | Lowers cutting resistance, increasing tool life by 30%+ | Parts requiring complex CNC machining (par ex., corps de vannes) |

2. What Are the Main Heat Treatment Methods for Aluminum Alloy Die Castings?

Different methods target specific property improvements. Below is a detailed comparison of the most widely used techniques, including the recommended T5 artificial aging processus.

2.1 Key Heat Treatment Methods: Une comparaison côte à côte

| Méthode | Définition | Paramètres critiques | Core Functions | Applications idéales |

| Recuit | Heat to high temp (300-400°C) + slow furnace cooling | Heating rate: 50-100°C/h; Holding time: 2-4h | Decomposes second-phase particles; reduces hardness | Pre-machining of hard castings (par ex., aluminium – silicon alloys) |

| Solution Treatment | Heat near eutectic melting point (450-550°C) + rapid quenching | Temp < overburn temp; Quench transfer time < 10s | Maximizes dissolution of strengthening elements (par ex., Cu, Mg); Améliore la résistance à la corrosion | Parts requiring high strength (par ex., aircraft fittings) |

| Aging Treatment | Post-solution heating to 120-200°C + heat preservation | Holding time: 4-12h; Cooling method: Air/water | Promotes precipitation of strengthened phases; Balances strength and plasticity | Follow-up to solution treatment (par ex., pièces de structure automobile) |

| T5 Artificial Aging (Recommended) | Low-temperature start → ramp to target temp (150-180°C) + refroidissement par air | Heating rate: 30-50°C/h; Holding time: 6-8h | Avoids high-temperature deformation/pore expansion; Lowers costs by 15-20% contre. T6 | Complex thin-walled parts (par ex., smartphone midframes) or high-gas-content castings |

| Cold-Hot Cycle Treatment | 3-5 cycles of heating (200-300°C) + refroidissement (-20 to 0°C) | Temps de cycle: 2-3h/cycle; Temperature variation: ±5°C | Stabilizes phase structure; Ensures dimensional accuracy (±0,01mm) | Ultra-precision parts (par ex., composants de dispositifs médicaux) |

3. What Critical Factors Must Be Controlled During Heat Treatment?

Even the best method fails without strict process control. Below are 5 non-negotiable considerations, presented as a checklist for practical use:

3.1 Essential Control Factors

- Contrôle de la température:

- Risk of too high: Overheating (grain growth) ou déformation (jusqu'à 5% dimensional deviation).

- Risk of too low: Failure to achieve desired strength (tensile strength may drop by 30%).

- Solution: Use digital thermostats with ±2°C accuracy.

- Time Management:

- Holding time depends on: Alloy type (par ex., Al – Mg alloys need 2-3h; Al – Cu alloys need 4-6h) and casting thickness (add 1h for every 10mm thickness).

- Consequence of mismatch: Too long → oxidation; Too short → incomplete phase transformation.

- Humidité & Atmosphere:

- Humidity limit: < 40% RH (to prevent oxidation and surface pitting).

- Protective atmosphere: Use nitrogen or argon (reduces surface defects by 80% contre. air heating).

- Cooling Method:

- Quenching medium selection (based on part needs):

| Moyen | Cooling Speed | Suitable Parts |

| Water | Rapide (100-150°C/s) | Pièces à haute résistance (par ex., engrenages) |

| Huile | Modéré (20-50°C/s) | Parts sensitive to internal stress (par ex., thin plates) |

| Air | Lent (5-10°C/s) | Low-deformation requirements (par ex., pièces décoratives) |

- Material Adaptability:

- Different alloys respond differently:

- Al – Si alloys: Excellent for annealing (améliore l'usinabilité).

- Al – Cu alloys: Require solution + vieillissement (maximizes strength).

- Al – Mg alloys: Avoid high-temperature solution treatment (risk of burning).

4. Yigu Technology’s Perspective on Aluminum Alloy Die Casting Heat Treatment

Chez Yigu Technologie, nous croyons aluminum alloy die casting heat treatment is not just a “post-processing step” but a “design-in factor” pour pièces hautes performances. Our experience shows that 70% of casting failures stem from mismatched heat treatment schemes—for example, using T6 treatment on thin-walled parts often causes warping, while T5 can reduce this risk by 90%.

We recommend integrating heat treatment requirements into the early design stage: Pour pièces complexes, simulate stress distribution first to select methods like T5 or cold-hot cycling; for corrosion-sensitive parts, combine solution treatment with a protective atmosphere. By balancing process efficiency and performance goals, we help customers cut costs by 15-25% while improving part lifespan by 2-3x.

5. FAQ: Common Questions About Aluminum Alloy Die Casting Heat Treatment

T1: Can all aluminum alloy die castings be heat-treated?

Non. Par exemple, high-silicon aluminum alloys (Si content > 12%) have limited response to solution/aging treatment, so annealing is preferred. Always check the alloy’s chemical composition first.

T2: How does T5 treatment compare to the traditional T6 process?

T6 (solution + full artificial aging) offers higher strength but risks deformation. T5 (direct artificial aging) is simpler, moins cher, and better for thin-walled/complex parts—though its tensile strength is 5-10% lower than T6.

T3: What should I do if a casting cracks after heat treatment?

D'abord, check if the quenching transfer time was too long (causing precipitation) or if the cooling medium was too fast (inducing stress). Adjust parameters: Extend holding time by 1h or switch to a slower cooling medium (par ex., from water to oil).