Si vous êtes un concepteur ou un fabricant de produits cherchant à créer des tableaux d'impression 3D précis pour le développement de nouveaux produits., l'une des premières questions que vous poserez est: «Quels matériaux dois-je utiliser?" Le choix du bon matériau affecte directement la durabilité de votre planche à main, apparence, et si cela correspond aux performances de votre produit final. Let’s break down the most common 3D printing handboard materials, leurs utilisations, and how to pick the best one for your project.

Common 3D Printing Handboard Materials & Their Key Details

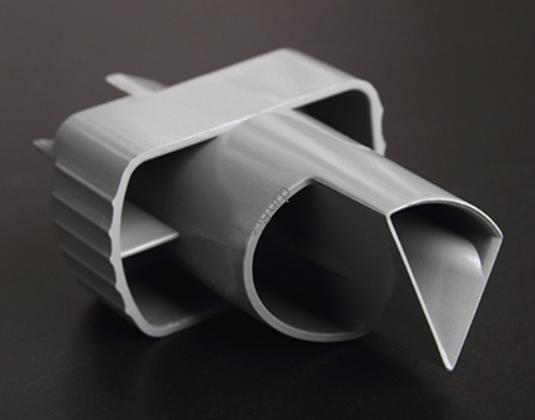

To make it easy for you to compare, we’ve organized the top materials into a clear table. Each entry includes the material name, suitable 3D printing technology, main advantages, and typical handboard applications.

| Type de matériau | Suitable 3D Printing Technology | Avantages clés | Typical Handboard Applications | Average Cost (Par kg) |

| Plastiques techniques (ABS/PLA) | FDM (Modélisation des dépôts fondus) | Faible coût, facile à imprimer, bonne résistance aux chocs (ABS) | Prototypes de produits de consommation (jouets, household goods), structural test parts | \(20 – \)50 |

| Photopolymer Resins | ANS (Stéréolithographie)/DLP (Traitement numérique de la lumière) | Détail élevé, smooth surface finish, haute précision | Prototypes de haute précision (boîtiers électroniques, jewelry models), visual display handboards | \(80 – \)150 |

| Rubber-Like Materials | FDM/SLS (Frittage sélectif au laser) | Flexible, élastique, good grip | Handboards for soft parts (poignées, joints, shoe soles) | \(60 – \)120 |

| Matériaux métalliques (Titanium Alloy/Stainless Steel) | GDT (Fusion laser sélective)/SLS | Haute résistance, résistance à la corrosion, résistance à la chaleur | Industrial part prototypes (composants automobiles, pièces aérospatiales), functional test handboards | \(300 – \)800 |

| Matériaux Céramiques | SLA/SLS | Résistance aux hautes températures, haute précision, attrait esthétique | Artistic handboards, dental implant models, high-temperature test parts | \(150 – \)300 |

| Matériaux composites (Carbon Fiber-Reinforced Plastic) | FDM/SLS | Léger, haute résistance, rigide | High-performance handboards (cadres de drones, sports equipment prototypes) | \(100 – \)250 |

| Food Materials (Sugar/Chocolate) | Specialized Food 3D Printers | Edible, customizable shapes | Promotional handboards (food product samples, decorative cake toppers) | \(50 – \)100 |

| Gypsum Materials (Colored) | Jet de liant | Vibrant colors, easy to shape, faible coût | Visual display handboards (sculptures, modèles architecturaux) | \(30 – \)80 |

| Artificial Bone Powder | SLS/SLM | Biocompatible, matches bone structure | Medical handboards (orthopedic implant prototypes, guides chirurgicaux) | \(500 – \)1,200 |

How to Choose the Right Material for Your 3D Printing Handboard

Picking a material isn’t just about cost—it needs to fit your handboard’s purpose. Voici 4 key factors to consider, with simple questions to guide your decision:

1. What’s the Handboard’s Main Use?

- If it’s for visual display (par ex., showing a product’s design to clients), go for résines photopolymères (surface lisse) ou colored gypsum (couleurs vibrantes).

- If it’s for tests fonctionnels (par ex., checking if a part can withstand pressure), choose plastiques techniques (ABS) ou metal materials (haute résistance).

- If it’s for medical or biocompatible needs (par ex., orthopedic prototypes), artificial bone powder is the top choice.

2. What’s Your Budget?

- Budget-friendly options (under $50/kg): PLA (a type of engineering plastic) and gypsum. Great for simple visual handboards.

- Mid-range options (\(50 – \)200/kilos): ABS, rubber-like materials, et matériaux composites. Balanced for most testing and display needs.

- High-end options (over $200/kg): Métaux (alliage de titane) and artificial bone powder. For industrial or medical-grade handboards.

3. Do You Need Special Properties?

- Flexibilité: Rubber-like materials are the only choice for handboards that need to bend (par ex., a prototype of a phone case with a soft edge).

- Résistance à la chaleur: Ceramic materials or stainless steel work best if your handboard will be exposed to high temperatures (par ex., a prototype of a kitchen appliance part).

- Léger & Force: Composite materials like carbon fiber-reinforced plastic are perfect for handboards that need to be strong but not heavy (par ex., a drone frame prototype).

Yigu Technology’s View on 3D Printing Handboard Materials

Chez Yigu Technologie, we believe that the right 3D printing handboard material is the bridge between design ideas and market-ready products. Based on our work with hundreds of manufacturing clients, plastiques techniques (ABS/PLA) et résines photopolymères are the most versatile choices for most new product 研发 (R.&D) projects—they balance cost, ease of printing, et performances. For industrial clients needing high-strength handboards, we recommend carbon fiber composites or stainless steel, as they replicate the durability of final parts. We also see growing demand for biocompatible materials like artificial bone powder in medical R&D, and we’re committed to offering these options to support innovative healthcare solutions.

FAQ

Q1: Can I use PLA for functional test handboards?

PLA is great for visual handboards, but it’s less durable than ABS. For light functional tests (par ex., checking fit), it works. But for tests involving impact or heat, ABS or metal is better.

Q2: Are rubber-like materials suitable for long-term handboard use?

Rubber-like materials can degrade slightly over time (especially if exposed to sunlight), so they’re best for short-term handboards (par ex., 1-3 des mois de tests). For longer use, consider adding a protective coating.

Q3: How much does a metal 3D printing handboard cost compared to a plastic one?

En moyenne, a metal handboard costs 5-10 times more than a plastic one. Par exemple, a small plastic handboard (100g) might cost \(5-\)10, while a similar metal handboard could cost \(50-\)100. The exact price depends on the metal type (titanium is more expensive than stainless steel) and handboard size.