Les bouchons en silicone haute température sont des composants élastomères spécialisés conçus pour résister à une chaleur extrême tout en scellant ou en protégeant les ouvertures. (par ex., trous, fils de discussion) dans l'industrie, médical, et applications liées à l'alimentation. Made from high-purity silicone rubber blended with heat-resistant additives, ils maintiennent l'élasticité et l'intégrité structurelle même à des températures bien supérieures aux produits en silicone standard. But what sets them apart from regular silicone plugs, how are they made, and how do you choose the right one?

1. Caractéristiques clés: Why High-Temperature Silicone Plugs Excel

High-temperature silicone plugs outperform standard silicone plugs and other sealing materials (par ex., caoutchouc, plastique) in four critical areas. The table below highlights their unique advantages:

| Caractéristiques | High-Temperature Silicone Plugs | Standard Silicone Plugs | Rubber/Plastic Plugs |

| Résistance à la température | Résiste 200–350°C (à court terme: 350°C pour 2 heures); no cracking or hardening | Only tolerates up to 150°C; deforms above 180°C | Melts or brittle at 80–120°C |

| Physical Durability | Résistance à la traction: 3–8MPa; allongement à la rupture: >400%; no permanent deformation after compression | Résistance à la traction: 2–5MPa; élongation: <300%; prone to set after repeated use | Low tensile strength (<2MPa); cracks easily with friction |

| Chemical Stability | Résiste aux acides (pH 2–12), alcalis, huiles, et solvants; no corrosion or swelling | Limited resistance to strong acids/alkalis; swells in oil | Dissolves or degrades in most chemicals |

| Conformité à la sécurité | Food-grade variants meet FDA/GB standards; medical-grade options are biocompatible (no tissue irritation) | Rarely food/medical certified; may contain harmful additives | Often non-toxic but not suitable for food/medical contact |

2. Matériels & Manufacturing Process: Building Heat Resistance

The performance of high-temperature silicone plugs starts with material selection and strict production control. Below is a linear breakdown of the key steps:

Étape 1: Material Blending (The Foundation of Heat Resistance)

- Base Silicone: Utiliser fumed silica gel (haute pureté, low impurity content) as the base—this boosts density and heat resistance compared to precipitated silica.

- Additive Integration: Mix in specialized additives:

- Heat stabilizers (par ex., oxyde de fer) to prevent thermal oxidation at 300°C+.

- Antioxidants to extend aging resistance (service life: 5+ years in high-heat environments).

- For food/medical grades: Add non-toxic plasticizers (no phthalates) to maintain flexibility.

Étape 2: Moulage (Shaping for Precision)

Choose a molding method based on the plug’s shape and volume:

- Moulage par compression: Ideal for high-volume standard shapes (par ex., blind hole plugs). Heat silicone compound in a mold (160–180°C) under pressure (10–20MPa) to form the plug.

- Extrusion Molding: Utilisé depuis longtemps, cylindrical plugs (par ex., through-hole types). Push silicone through a die, then cut to length after cooling.

Étape 3: Vulcanization (Locking in Performance)

- Primary Vulcanization: Cure the molded plug in an oven (180–200°C) for 5–10 minutes to set the basic shape.

- Secondary Vulcanization: Post-cure at 200–220°C for 2–4 hours to remove volatile by-products. This step critical—without it, the plug may lose heat resistance over time.

Étape 4: Quality Testing

- Vérifier résistance à la température: Expose samples to 350°C for 2 heures; ensure no deformation or hardness change.

- Vérifier précision dimensionnelle: Use calipers to confirm diameter (±0.1mm tolerance for precision plugs).

- For food/medical grades: Conduct toxicity tests (no heavy metals, no VOCs).

3. Applications par industrie: Where Heat Resistance Matters

High-temperature silicone plugs solve unique problems across sectors. Here’s how they’re used in key industries:

| Industrie | Cas d'utilisation typiques | Recommended Plug Type | Avantages clés |

| Fabrication industrielle | – Protecting screw holes/process holes during high-temperature spraying (250°C+) or electroplating.- Sealing communication cabinet through-holes to prevent dust/chemical ingress. | Countersunk thread type (for threaded holes); large-diameter plugs (25–50mm for big process holes) | Resists paint/chemicals; réutilisable (jusqu'à 50 fois) |

| Dispositifs médicaux | – Sealing medicine bottle necks (prevents drug contamination).- Protecting medical instrument ports during autoclave sterilization (134°C, haute pression). | Small-diameter blind hole plugs (3–10mm); medical-grade silicone | Biocompatible; withstands repeated sterilization |

| Transformation des aliments | – Sealing food can lids (maintains freshness).- Covering baking mold holes (prevents batter leakage during oven heating, 220°C). | Food-grade transparent plugs; heat-resistant up to 250°C | Non toxique; facile à nettoyer (passe au lave-vaisselle) |

| Scientific Research | – Sealing laboratory flasks/test tubes during high-temperature experiments (par ex., distillation at 200°C).- Protecting sensor ports in environmental chambers (cycle de température: -40°C à 300°C). | Heat-resistant through-hole plugs; flexible variants (for irregular openings) | Withstands extreme temperature swings; ensures airtight seals |

4. Spécification & Shape Guide: Choose the Right Fit

Selecting the wrong size or shape leads to leaks or damage. Use this table to match plugs to your needs:

| Specification/ Shape | Key Details | Idéal pour |

| Diamètre (Common Sizes) | – Petit: 3–10mm (medical bottles, tubes à essai)- Moyen: 11–20mm (industrial process holes)- Grand: 21–50mm (automotive/communication cabinets) | Choose based on the hole’s inner diameter (add 0.5–1mm for a tight seal) |

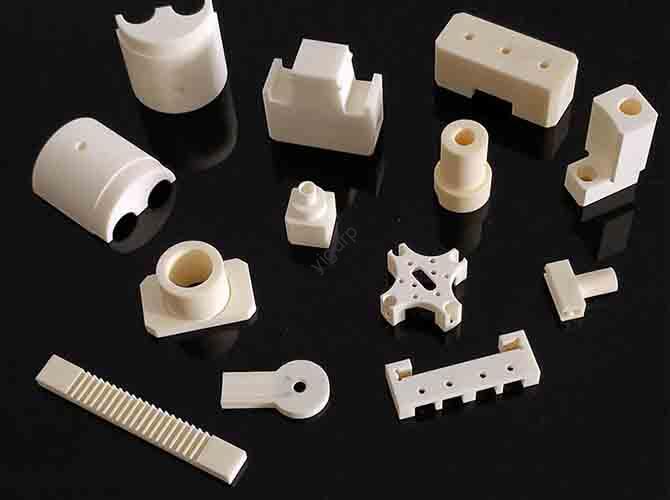

| Shape Types | – Through-Hole Type: Hollow center; fits holes that need to be penetrated (par ex., sensor wires).- Blind Hole Type: Solid bottom; seals one-end closed holes (par ex., medicine bottle necks).- Countersunk Thread Type: Has a recessed top; fits countersunk threaded holes (par ex., pièces de machines). | Through-hole: Wire/cable pass-throughsBlind hole: Full sealing needsCountersunk: Threaded hole protection |

5. Yigu Technology’s Perspective on High-Temperature Silicone Plugs

Chez Yigu Technologie, we see high-temperature silicone plugs as “heat-resistant guardians” for critical components. Pour les clients industriels, notre countersunk thread plugs reduce rework rates by 60% during high-temperature spraying—they stay in place even at 300°C and leave no residue. For medical partners, notre FDA-certified blind hole plugs subir 100+ autoclave cycles without losing flexibility, ensuring drug safety.

Regarder vers l'avenir, we’ll focus on two innovations: 1) Developing ultra-high-temperature plugs (up to 400°C) for aerospace applications, et 2) Creating custom shapes (par ex., irregular holes) with 3D printing technology to reduce lead time by 30%. Our goal is to make high-temperature silicone plugs more adaptable to extreme and niche scenarios.

FAQ

- How to clean and reuse high-temperature silicone plugs?

For industrial plugs: Wipe with a solvent (par ex., alcool isopropylique) to remove paint/chemicals; avoid sharp tools that scratch the surface. For food/medical plugs: Wash with warm soapy water or autoclave (134°C). Most plugs can be reused 30–50 times if no cracks or deformation occur.

- Can high-temperature silicone plugs be used in low-temperature environments?

Yes—they maintain flexibility from -60°C à 350°C. This makes them ideal for applications with temperature swings (par ex., outdoor industrial equipment that faces cold nights and hot days).

- What’s the difference between food-grade and industrial-grade high-temperature silicone plugs?

Food-grade plugs use non-toxic additives (no heavy metals/VOCs) and meet FDA/GB food safety standards; they’re safe for direct food contact. Industrial-grade plugs may contain cost-effective additives (par ex., carbon black for UV resistance) that are not food-safe—never use them in food processing.