1. Usinage pré-CNC: Design and Preparation for Pet Water Dispenser Prototypes

Before initiating Usinage CNC for the pet water dispenser prototype, une étape systématique de conception et de préparation est essentielle pour répondre aux exigences fonctionnelles., sécurité, et exigences relatives aux animaux de compagnie. Cette étape suit une séquence linéaire, avec les détails clés organisés dans le tableau ci-dessous.

| Design Step | Exigences clés | Recommended Materials |

| Product Demand Analysis | Core functions: Automatic circulation (pump flow 500-800mL/min) or manual refill; Capacité: Water tank (1-2L); Additional features: filtration system (replaceable filter element), splash-proof edge (height ≥15mm), low-water level reminder; Safety: No sharp corners (pet mouth protection), matériaux non toxiques; Reserve space for pump, filter tank, water pipe interface (Φ8-10mm), and power port (DC 5V). | – |

| Structural Design | Split components: Water tank (upper/lower), base, pump support, filter tank, water pipe connector; Optimize internal flow path (smooth water circulation, no dead corners); Design sealing grooves (width 2-3mm, depth 1-1.5mm) for waterproofing; Add anti-slip pads (silicone) on base bottom. | – |

| 3Modélisation D & Dessin | Use CAD software (SolidWorks, UG NX) to create 3D models (tolerance ±0.1mm for plastic, ±0.05mm for metal); Mark key dimensions: Water tank inner diameter (matches capacity), pump mounting hole (Φ30mm), filter tank size (fits standard filter); Export 2D drawings (DXF) with surface roughness requirements (Ra3.2 for water contact parts). | – |

| Sélection des matériaux | Prioritize non-toxicity, résistance à la corrosion, et usinabilité, matching mass production standards. | Water Tank/Base: Acrylique (transparent, easy to observe water level) ou ABS (non toxique, résistant aux chocs, thickness 2-3mm); Pump Support/Filter Tank: ABS/PC alloy (isolation, résistant à l'usure); Water Pipe Connector: Acier inoxydable 304 (résistant à la corrosion, de qualité alimentaire); Internal Brackets: PA66 nylon (non toxique, léger). |

| Material Pretreatment | Cut raw materials into blanks (leave 0.5-1mm machining allowance): Acrylic/ABS via laser cutting, stainless steel via bandsaw; Anneal stainless steel (1050-1100°C pour 1-2 heures) pour réduire le stress; Dry ABS/acrylic (80-100°C pour 2-3 heures) pour éliminer l'humidité (prevents machining bubbles); Clean blanks with alcohol to remove oil. | – |

2. CNC Machining Preparation for Pet Water Dispenser Prototypes

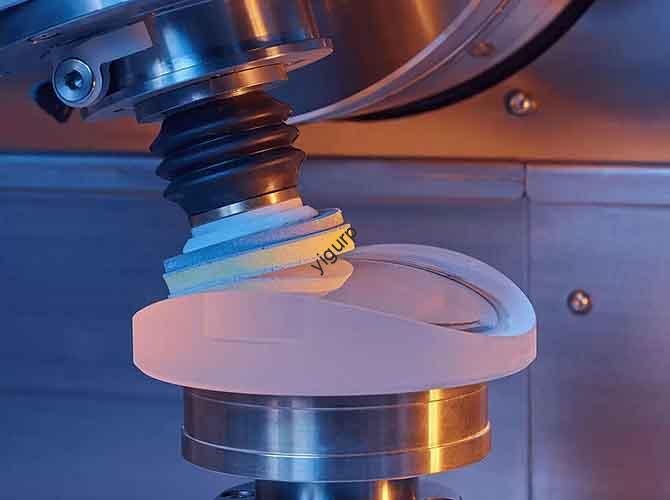

Adequate preparation before formal machining ensures efficiency and precision in Usinage CNC for pet water dispenser prototypes. This section covers tool selection, parameter setting, and fixture design.

2.1 Material and Tool Selection

The choice of materials and tools directly affects machining quality and efficiency. The table below provides detailed recommendations:

| Category | Specific Options | Application Scenarios |

| Housing Materials | Acrylic plate (2-3mm), ABS plate (2-3mm), ABS/PC alloy plate (1.5-2mm) | Acrylic for transparent water tanks; ABS for non-transparent bases; ABS/PC for filter tanks. |

| Matériaux métalliques | Acier inoxydable 304 tige (diameter 8-10mm), PA66 nylon sheet (1.5-2mm) | Stainless steel for water pipe connectors; nylon for internal brackets. |

| Rough Machining Tools | Φ8-10mm flat-bottom cutter (acrylic/ABS), Φ6-8mm flat-bottom cutter (acier inoxydable) | Quick material removal for large components (water tank, base). |

| Finishing Tools | Φ3-5mm ball-head cutter (bords incurvés), Φ1-2mm drill bit (petits trous), Φ2-3mm root-clearing cutter (sealing grooves) | Ensure smooth surfaces (Ra3.2 for water contact parts) and precise details (sealing grooves, trous de montage). |

| Special Tools | M3-M4 taps (trous filetés), laser engraver (water level marks), food-grade polishing tools | Process assembly threads; engrave functional marks (par ex., “Max Water Level”); polish stainless steel to food-grade standards. |

2.2 Parameter Setting and Fixture Design

Scientific parameter setting and stable fixtures prevent machining errors.

| Link | Key Operations | But & Effect |

| Paramètres de coupe | – Acrylique: High speed (15000-20000 RPM), low feed rate (100-200mm/min), cutting depth 0.2-0.3mm (avoids cracking);- ABS: Medium speed (8000-12000 RPM), feed rate 200-300mm/min, cutting depth 0.5mm;- Acier inoxydable: Low speed (5000-8000 RPM), feed rate 50-100mm/min, cutting depth 0.1-0.2mm (prevents tool wear). | Ensure machining efficiency; avoid material damage (par ex., acrylic cracking, stainless steel deformation). |

| Conception des luminaires | – Acrylic/ABS: Use vacuum adsorption platform (even pressure, no scratches); for curved water tanks, use custom jigs with soft pads.- Acier inoxydable: Use precision vise with rubber jaws (prevent surface damage); for small connectors, use multi-point clamping fixtures.- Nylon parts: Use lightweight clamps (avoid deformation from excessive force). | Maintain workpiece stability; protect surface finish (critical for transparent acrylic); ensure dimensional accuracy. |

3. Core CNC Machining Process for Pet Water Dispenser Prototypes

The formal CNC machining process transforms design models into physical parts, with strict control over each step to ensure functionality and safety.

3.1 Main Component Machining

Different components require targeted machining steps, as detailed below:

| Component | Roughing Steps | Finishing Steps |

| Water Tank (Acrylique) | 1. Mill outer contour (matches design size, retain 0.5mm allowance);2. Mill inner cavity (depth 150-200mm for 1-2L capacity);3. Drill pump mounting hole (Φ30mm) and water pipe interface hole (Φ8-10mm). | 1. Polish inner/outer surfaces (Ra3.2, mirror effect for transparency);2. Chamfer all edges (R1mm, prevent pet mouth scratches);3. Machine sealing grooves (width 2mm, depth 1mm) at tank bottom. |

| Base (ABS) | 1. Mill flat outer shape (retain 0.5mm allowance);2. Mill pump cavity (depth 40-50mm) and filter tank slot (size matches filter);3. Drill power port cutout (DC 5V size). | 1. Smooth cavity walls (Ra3.2);2. Tap M3 threaded holes (for water tank fixation);3. Deburr all holes (prevent cable damage). |

| Water Pipe Connector (Acier inoxydable) | 1. Turn rod into cylindrical blank (diameter 8-10mm, retain 0.3mm allowance);2. Mill connection threads (M8-M10). | 1. Polish surface (Ra0.8, food-grade standard);2. Remove burrs (prevent water leakage);3. Pass corrosion resistance test (soak in 5% salt water for 24 heures, pas de rouille). |

| Filter Tank (ABS/PC) | 1. Mill box shape (retain 0.5mm allowance);2. Mill inner cavity (fits filter element, depth 80-100mm);3. Cut water inlet/outlet slots (width 5mm). | 1. Smooth cavity walls (Ra3.2, avoid filter jamming);2. Chamfer slots (C0.5mm);3. Tap M3 holes (for cover fixation). |

3.2 Key Detail Machining

Critical details directly affect the prototype’s functionality and pet safety:

- Sealing Groove Machining: Control groove width (2mm) and depth (1mm) with tolerance ±0.05mm; Ensure groove uniformity (no depth deviation >0.03mm) to fit silicone gaskets (waterproof, IPX7 standard).

- Water Level Mark Engraving: Use laser engraving on acrylic water tanks to mark “Max” (upper limit) et “Min” (lower limit) lignes; Engraving depth 0.2-0.3mm (clear visibility, no water leakage).

- Pump Mounting Hole Machining: Ensure hole coaxiality (≤0,05 mm) with water pipe interface; Add positioning boss (height 2mm) to fix the pump (prevent vibration displacement).

- Edge Chamfering: All components in contact with pets (water tank edges, base corners) must be chamfered (R1mm) or rounded (R2mm) to avoid scratching pets’ mouths or paws.

3.3 Machining Quality Inspection

Conduct in-process checks to ensure quality:

- Contrôle dimensionnel: Utilisez des pieds à coulisse numériques (outer dimensions, tolerance ±0.1mm for plastic, ±0.05mm for metal) and coordinate measuring machine (MMT) (sealing grooves, pump holes, tolerance ±0.03mm).

- Surface Quality Check: Use surface roughness meter (Ra3.2 for water contact parts, Ra6.3 for non-contact parts); Check for scratches (no visible scratches >0.3mm on acrylic) and burrs (no sharp edges).

- Safety Test: Verify material non-toxicity (pass RoHS certification); Check stainless steel connectors for food-grade compliance (no heavy metal leakage).

4. Post-Processing and Assembly of Pet Water Dispenser Prototypes

Post-processing enhances safety and aesthetics, while precise assembly ensures functionality.

4.1 Traitement de surface

Different materials require targeted treatment to meet safety and design goals:

| Matériel | Méthode de traitement de surface | But & Effect |

| Acrylique (Water Tank) | Polissage + Anti-Scratch Coating | Polishing ensures transparency (light transmittance ≥90%); anti-scratch coating (thickness 5-10μm) resists daily wear (no scratches after 500 steel wool tests). |

| ABS (Base/Filter Tank) | Peinture (Non-Toxic Paint) + Silk Screen | Painting uses pet-safe, odorless paint; silk screen prints brand logos and warning signs (par ex., “Keep Away from Fire”). |

| Acier inoxydable (Connector) | Passivation + Polissage | Passivation (nitric acid solution) améliore la résistance à la corrosion (salt spray test ≥72 hours); polishing achieves food-grade surface (Ra0.8). |

| Nylon (Supports) | Ébavurage + UV Sterilization | L'ébavurage supprime les arêtes vives; UV sterilization (254longueur d'onde nm, 30 minutes) ensures non-toxicity (no bacteria residue). |

4.2 Assembly and Functional Testing

Scientific assembly and strict testing ensure the prototype meets pet safety and functional requirements.

4.2.1 Assembly Process

Follow this sequence to avoid errors:

- Pre-Assembly Check: Inspect all parts for defects (no scratches, dimensional deviation ≤0.1mm); Prepare auxiliary materials (joints en silicone, non-toxic glue, food-grade hoses, vis).

- Component Installation:

- Water Tank Assembly: Place silicone gasket in the tank’s sealing groove; Fix tank to base with M3 screws (torque 0.8-1N·m, even force to avoid cracking acrylic).

- Pump & Filter Installation: Mount pump on the support (snap-fit or screws); Connect pump to water pipe connector (use food-grade hose); Install filter element in the filter tank (snap-fit, ensure tight seal).

- Pipeline Connection: Connect water pipe from pump to tank inlet, and from tank outlet to filter tank; Check for pipeline kinks (ensure smooth water flow).

- Electrical Installation: Connect pump to power port (solder joints firm, wrap with non-toxic tape); Install low-water level sensor (align with “Min” mark).

- Final Check: Ensure no loose parts; Verify pipeline connections (no leakage); Check sensor alignment (no offset).

4.2.2 Tests fonctionnels

Conduct comprehensive tests to validate performance and safety:

- Safety Tests:

- Waterproof Test: Fill tank to “Max” level, run pump for 24 heures (no water leakage, IPX7 compliant);

- Non-Toxicity Test: Soak all water-contact parts in water for 48 heures, test water for heavy metals (lead, mercury ≤0.01mg/L);

- Impact Test: Drop base from 0.5m (foam pad, no structural damage, no sharp edges exposed).

- Functional Tests:

- Circulation Test: Run pump (flow 500-800mL/min, no noise >45dB); Check water flow (no dead corners, uniform circulation);

- Filtration Test: Add simulated impurities (10μm particles) to water, run filter for 1 heure (impurity removal rate ≥95%);

- Low-Water Level Test: Drain water to “Min” mark, verify sensor triggers pump shutdown (response time ≤10s).

- Pet Experience Tests:

- Accessibility Test: Simulate pet drinking (use model paw/mouth), verify no difficulty reaching water (tank edge height ≤50mm);

- Durability Test: Simulate pet scratching the base (100 times with 5N force, no paint peeling, no structural damage).

5. Application Scenarios of CNC Machined Pet Water Dispenser Prototypes

CNC machined pet water dispenser prototypes serve multiple purposes in product development and market promotion:

| Application Scenario | Specific Uses | Advantage of CNC Machining |

| Product Design Verification | Test waterproof performance, filtration efficiency, and pet safety; Optimize structure (par ex., adjust tank edge height for easy drinking). | Haute précision (±0,05 mm) ensures accurate simulation of mass production models; supports rapid iteration (modify 3D models, re-machine in 2-3 jours). |

| Market Research | Display at pet product exhibitions; Collect user feedback on appearance (transparent/non-transparent) et fonctionnalité (noise level, filter replacement ease); Adjust mass production plans. | Prototype appearance/functionality match final products; attracts pet owners (de haute qualité, pet-safe design). |

| Small-Batch Customization | Pet shops (custom logos), high-end pet care centers (large-capacity tanks); Produce ≤50 units without opening molds. | Flexible (adapt to custom sizes/colors quickly); rentable (no mold fees, lower than injection molding for small batches). |

| Educational Training | Disassemble to demonstrate water circulation principles, Processus d'usinage CNC; Suitable for industrial design/pet product development teaching. | Clear internal structure (easy to observe components); sûr (meets pet safety standards, no toxicity risk). |

6. Key Precautions for CNC Machining Pet Water Dispenser Prototypes

To ensure quality, sécurité, et efficacité, observe these precautions:

- Safety Priority: All materials must be non-toxic (pass RoHS, FDA food-grade certifications); Avoid sharp edges (chamfer all pet-contact parts to R1mm); Stainless steel parts must be corrosion-resistant (prevent rust from contaminating water).

- Contrôle de précision: Sealing groove tolerance ±0.05mm (ensures waterproofing); Pump hole coaxiality ≤0.05mm (prevents vibration noise); Acrylic parts reserve ±0.1mm shrinkage (avoids post-machining size deviation).

- Optimisation des coûts: CNC machining is ideal for ≤100 units; Pour la production de masse (>1000 units), switch to injection molding (ABS/acrylic) to reduce cost by 50-60%. Simplify complex curves (par ex., replace irregular tank shapes with regular cylinders) to shorten toolpaths.

- Environmental Protection: Use non-toxic, biodegradable coolants for machining; Dispose of plastic/metal waste in accordance with environmental regulations (recycle stainless steel scraps).

Yigu Technology’s Viewpoint

Chez Yigu Technologie, we believe CNC machining is the core to developing safe and user-friendly pet water dispenser prototypes. It enables precise control of critical structures—from pet-safe edge chamfers (R1mm) to waterproof sealing grooves (±0,05 mm)—and supports rapid iteration, which is vital for balancing functionality (circulation, filtration) and pet safety (non-toxicity, no sharp edges). When producing these prototypes, we focus on two core aspects: material-safety matching (acrylic for transparent tanks, food-grade stainless steel for connectors) et optimisation des processus (vacuum adsorption for acrylic, low-speed machining for stainless steel). By integrating strict quality control from design to testing, we help clients shorten development cycles by 20-25% and mitigate mass production risks. Looking ahead, we will apply AI-driven parameter optimization to CNC machining, further improving efficiency while maintaining ±0.03mm precision for safer, more reliable pet water dispenser prototypes.