Dans le monde trépidant de la fabrication avancée, 3D printing titanium alloys has emerged as a transformative technology. Les alliages de titane eux-mêmes sont appréciés pour leur combinaison unique de résistance et de légèreté., mais lorsqu'il est associé à l'impression 3D, ils libèrent un potentiel encore plus grand en résolvant des défis de longue date dans des secteurs comme l'aérospatiale et les dispositifs médicaux. Whether you’re an engineer designing high-performance parts, a purchaser sourcing cost-effective manufacturing solutions, or a business owner looking to innovate, understanding the advantages of 3D printing titanium alloys est essentiel. This article breaks down these advantages, uses real-world examples to validate them, and provides practical insights to help you leverage the technology.

1. Avantages matériels: Why Titanium Alloys Shine in 3D Printing

Titanium alloys are not new to manufacturing, mais 3Impression D amplifies their natural strengths, making them more versatile than ever. Here’s how their material properties give them an edge:

- Rapport résistance/poids élevé: Titanium alloys are 40% plus léger que l'acier mais tout aussi solide. When 3D printed, this property becomes even more valuable—especially for aerospace parts where weight reduction directly improves fuel efficiency. Par exemple, Boeing used 3D printed titanium alloy components in its 787 Dreamliner, cutting the weight of certain engine parts by 30% and reducing fuel consumption by 15% per flight.

- Exceptional Corrosion Resistance: Titanium alloys resist rust and degradation even in harsh environments (par ex., saltwater, produits chimiques). 3Impression D preserves this trait because it uses controlled melting processes that avoid contamination. Dans le domaine médical, this means 3D printed titanium implants (comme les arthroplasties de la hanche) can last up to 20 years without corroding, compared to 10–15 years for traditional implants.

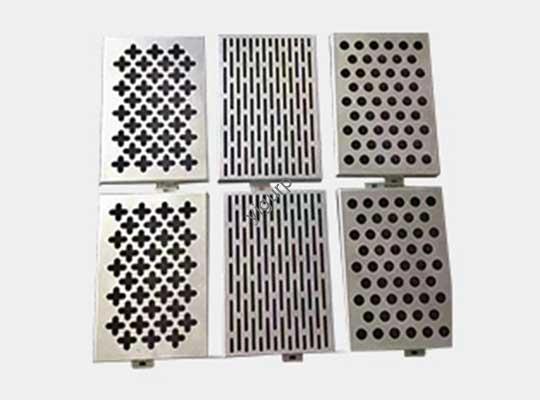

- Superior Geometric Forming Capabilities: Contrairement à l'usinage traditionnel, which often wastes material when shaping complex designs, 3D printing titanium alloys lets you create intricate structures (par ex., lattice patterns for medical implants) with minimal waste. This is a game-changer for engineers who need parts that are both lightweight and strong.

The table below summarizes how these material advantages solve common industry problems:

| Material Advantage | Problem It Solves | Industry Benefit |

| Rapport résistance/poids élevé | Heavy parts increasing fuel/energy costs | Improved efficiency in aerospace/automotive |

| Résistance à la corrosion | Parts degrading in harsh environments | Longer lifespan for implants and industrial parts |

| Geometric forming capabilities | Wasted material and limited design in machining | Complexe, lightweight parts with less waste |

2. Process Advantages: How 3D Printing Transforms Titanium Alloy Manufacturing

Le 3D printing process for titanium alloys isn’t just a “faster way to make parts”—it’s a more precise, flexible method that addresses traditional manufacturing flaws. Here are the key process advantages:

2.1 Diverse, Precision-Driven Printing Technologies

3D printing titanium alloys uses three main processes, chacun adapté à des besoins spécifiques. This diversity lets manufacturers choose the best method for their project:

| Process Name | Comment ça marche | Idéal pour | Accuracy Level |

| Powder Bed Melting (PBM) | Uses lasers to melt thin layers of titanium powder into shape | Petit, pièces complexes (par ex., implants médicaux) | ±0,05 mm |

| Direct Energy Deposition (DED) | Uses a nozzle to deposit melted titanium wire onto a base | Grandes pièces (par ex., aerospace structural components) | ±0,1mm |

| Jet de liant | Uses a binder to stick titanium powder together, then sinters (heats) il | Faible coût, pièces à grand volume (par ex., parenthèses) | ±0,2 mm |

Par exemple, Airbus uses DED 3D printing to make large titanium alloy wing spars for its A350 aircraft. The process lets them create parts up to 5 meters long with minimal waste—something impossible with traditional casting.

2.2 Streamlined Manufacturing Workflow

Traditional titanium alloy manufacturing involves multiple steps (par ex., forger, usinage) that take weeks. 3Impression D simplifies this to four core steps, réduisant les délais de livraison en 50% ou plus:

- Design Model: Create a 3D digital model using CAD software (par ex., SolidWorks). This step is flexible—engineers can easily tweak designs without retooling.

- Slicing Processing: Split the 3D model into thin layers (0.02–0,1 mm d'épaisseur) using slicing software (par ex., Traitement).

- Processus d'impression: The 3D printer melts titanium powder/wire layer by layer to build the part.

- Post-traitement: Remove support structures and add heat treatment to boost strength. For medical implants, this step may also include sterilization.

Un exemple concret: A medical device company in Germany reduced the production time of a titanium spinal implant from 6 semaines (usinage traditionnel) à 5 days using PBM 3D printing. This let them respond faster to urgent patient needs.

3. Application Advantages: Real-World Impact Across Industries

The advantages of 3D printing titanium alloys aren’t just theoretical—they’re proven in high-stakes industries. Below are two key application areas where the technology delivers tangible value:

3.1 Aérospatial: Léger, High-Strength Parts for Flight

Aerospace manufacturers face a critical challenge: making parts that are strong enough to withstand extreme forces but light enough to save fuel. 3D printing titanium alloys solves this perfectly.

- Exemple: Rolls-Royce, a leading jet engine maker, utilise 3D printed titanium alloy blades in its Trent XWB engine. The blades are 25% lighter than traditional blades and can withstand temperatures up to 1,200°C. This has helped the engine achieve a 15% reduction in fuel burn compared to older models.

- Key Benefit: 3Impression D lets aerospace companies create “topology-optimized” parts—designs that remove material only where it’s not needed. This reduces weight without sacrificing strength, a feat impossible with traditional methods.

3.2 Dispositifs médicaux: Custom Implants That Fit Perfectly

Every patient’s body is unique, but traditional medical implants are one-size-fits-all. 3D printing titanium alloys changes this by enabling fully customized implants.

- Exemple: Un États-Unis. hospital used 3Impression D to create a custom titanium alloy skull implant for a patient with a severe head injury. The team scanned the patient’s skull, designed an implant that matched the exact shape of the missing bone, and printed it in 48 heures. The implant integrated seamlessly with the patient’s body, reducing recovery time by 30% compared to a traditional implant.

- Key Benefit: Titanium alloys are biocompatible (they don’t react with the body), et 3Impression D lets doctors tailor implants to a patient’s specific anatomy. This reduces the risk of rejection and improves long-term outcomes.

4. Research Advantages: Pushing the Boundaries of Performance

3D printing titanium alloys is still evolving, and ongoing research is unlocking even more advantages. One standout example is the work of Zhang Zhefeng’s team at the Institute of Metals, Chinese Academy of Sciences:

- Breakthrough: The team developed a 3D printed titanium alloy with record-breaking fatigue resistance. Fatigue strength (a material’s ability to withstand repeated stress) is critical for parts like aircraft wings and medical implants. Their alloy achieved a fatigue strength of 900 MPa—higher than any other 3D printed titanium alloy in the world.

- How They Did It: By optimizing the “microstructure” of the alloy during printing (par ex., controlling the size of metal grains), the team eliminated weak points that cause fatigue. This shows that 3Impression D isn’t just a manufacturing tool—it’s a way to improve the fundamental properties of titanium alloys.

Yigu Technology’s Perspective on 3D Printing Titanium Alloys

Chez Yigu Technologie, we see 3D printing titanium alloys as a cornerstone of the next manufacturing revolution. Our clients in aerospace and medical fields often struggle with two pain points: long lead times for custom parts and high material waste. 3D printing titanium alloys solves both. We’re working to make this technology more accessible by partnering with printer manufacturers to offer integrated solutions—from material sourcing (high-quality titanium powder) to post-processing (traitement thermique pour plus de solidité). For small and medium-sized businesses, we provide training to help teams adopt the technology quickly. We believe that as 3Impression D costs drop and research advances, every manufacturer will soon be able to leverage the power of titanium alloys.

FAQ: Common Questions About 3D Printing Titanium Alloys

- Q: Is 3D printing titanium alloys more expensive than traditional manufacturing?

UN: It depends on the project. For small batches or custom parts, 3Impression D est souvent moins cher (it eliminates mold costs). Pour une production à grande échelle (10,000+ parties), traditional machining may still be more cost-effective—though 3Impression D costs are falling fast.

- Q: Do 3D printed titanium alloy parts have defects like porosity?

UN: Porosity (petits trous) can occur, but modern processes (par ex., PBM with laser calibration) reduce this to less than 0.1%. Post-processing steps like hot isostatic pressing (HIP) can eliminate remaining pores, ensuring parts meet industry standards.

- Q: What skills do I need to start 3D printing titanium alloys?

UN: You’ll need basic CAD design skills and knowledge of 3D printing processes (par ex., PBM vs. DED). Most printer suppliers offer training, and teams can partner with experts (comme la technologie Yigu) to set up workflows. No advanced metallurgy degree is required—just a willingness to learn!