Les vis à épaulement en acier inoxydable sont des fixations essentielles dans l'ingénierie de précision, offrant une polyvalence unique pour l’alignement, espacement, et applications porteuses dans tous les secteurs. Avec leur conception distincte à épaulement non fileté (plus grand en diamètre que la partie filetée), ces vis offrent des surfaces de montage stables tout en assurant une fixation sécurisée.. Dans ce guide, we’ll explore everything from material specifications and types to installation tips and sourcing strategies, helping you select the right stainless shoulder screws for your project.

What Are Stainless Shoulder Screws?

Stainless shoulder screws (also called stripper bolts) are specialized fasteners featuring three key sections: a precision-machined unthreaded shoulder, a threaded end for securing into a substrate, and a drive head for installation. The shoulder acts as a spacer or pivot point, maintaining precise alignment between components, while the stainless steel construction ensures durability and corrosion resistance.

Unlike regular screws or bolts, their unique design offers:

- Un lisse, unthreaded shoulder for rotational or sliding movement

- Consistent spacing between connected parts

- High load-bearing capacity on the shoulder surface

- Compatibility with precision assemblies requiring tight tolerances

Material Specifications: Why Stainless Steel Matters

Stainless steel is the material of choice for shoulder screws due to its balance of strength, résistance à la corrosion, et la rentabilité. The most common grades used are:

1. AISI 304 Acier inoxydable

- Propriétés clés: Contains 18% chromium and 8% nickel, offering excellent corrosion resistance in mild environments.

- Dureté: Typically 150–200 Brinell, providing good strength for general applications.

- Applications: Ideal for indoor, sec, or lightly exposed environments like electronics, machinerie, et des meubles.

2. AISI 316 Acier inoxydable (Less Common in Standard Offerings)

- Propriétés clés: Includes molybdenum for enhanced resistance to saltwater, produits chimiques, and high humidity.

- Idéal pour: Marin, médical, or industrial applications with harsh conditions.

All stainless shoulder screws in the ISO 7379 standard (like those featured here) utiliserAISI 304 acier inoxydable, ensuring RoHS compliance and suitability for most commercial and industrial uses.

OIN 7379: Standard Specifications for Stainless Shoulder Screws

LeOIN 7379 standard defines critical dimensions and tolerances for stainless shoulder screws, ensuring interchangeability and reliability. Key specifications include:

| Metric Size (d2) | Collar Diameter (d1) | Shoulder Length (l1) Range | Thread Length (l2) | Drive Size (A/F) |

|---|---|---|---|---|

| M3 | 0.1575 dans | 0.16–0.63 in | 0.12 dans | 2 mm |

| M4 | 0.1969 dans | 0.20–0.98 in | 0.16 dans | 2.5 mm |

| M5 | 0.2362 dans | 0.39–2.36 in | 0.18 dans | 3 mm |

| M6 | 0.3150 dans | 0.63–2.36 in | 0.22 dans | 4 mm |

| M8 | 0.3937 dans | 0.63–3.94 in | 0.28 dans | 5 mm |

| M10 | 0.4724 dans | 0.63–3.94 in | 0.35 dans | 6 mm |

| M12 | 0.6299 dans | 1.18–3.94 in | 0.43 dans | 8 mm |

Tolérances: The collar diameter (d1) features tight tolerances of -0.0006/-0.002 pouces, ensuring precise fit in holes. Shoulder length (l1) has a tolerance of +0.01 pouces, critical for consistent spacing.

Types and Variations of Stainless Shoulder Screws

Stainless shoulder screws come in several configurations to suit different applications:

1. Drive Types

- Hex Socket (Allen) Drive: Le type le plus courant, using a hex key for installation. Offers high torque transfer and is ideal for recessed applications.

- Slotted Drive: Less common but useful for simple, low-torque assemblies.

- Phillips Drive: Suitable for manual installation in light-duty applications.

2. Head Styles

- Cylinder Head: Standard design with a flat top, used in most general applications.

- Button Head: Rounded top for aesthetic or safety purposes (reduces snagging risk).

- Countersunk Head: For flush mounting in surfaces where protrusions are undesirable.

3. Special Features

- Knurled Head: Optional textured head for better grip during hand tightening (available under ISO 7379).

- Custom Lengths: Manufacturers offer tailored shoulder lengths for unique projects (par ex., 1/8” to 3/8” for 4-40 thread sizes).

Applications dans tous les secteurs

Stainless shoulder screws excel in applications requiring precision, résistance à la corrosion, et des performances fiables:

1. Automobile

Used in suspension systems, charnières de porte, and dashboard assemblies for alignment and pivot points. Their corrosion resistance prevents rust in undercarriage components.

2. Aérospatial

Critical for aircraft interiors, avionics mounting, et supports structurels. The tight tolerances ensure safety-critical parts maintain alignment under vibration.

3. Dispositifs médicaux

Ideal for surgical tools, équipement de diagnostic, and hospital furniture. AISI 304 stainless steel meets biocompatibility standards and resists cleaning chemicals.

4. Électronique

Secure circuit boards, boîtiers, and connectors. The non-threaded shoulder protects delicate components from over-tightening damage.

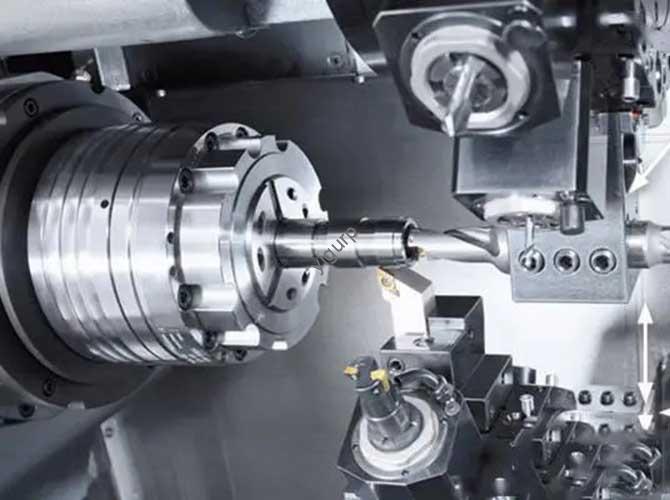

5. Machines industrielles

Used in robotics, convoyeurs, and assembly lines for bearing supports and linear motion guides. The smooth shoulder reduces friction in moving parts.

Installation and Fastening Best Practices

Proper installation ensures stainless shoulder screws perform optimally:

1. Pre-Installation Preparation

- Drill the Shoulder Hole: Match the hole diameter to the collar (d1) for a slip fit; use a reamer for tight tolerances if needed.

- Tap the Thread Hole: Ensure the threaded portion (d2) matches the tap size (par ex., M3 requires a 3mm tap).

2. Torque Specifications

- Maximum torque is limited by the shoulder-to-thread transition (weaker than the shoulder itself). For M3 screws, avoid exceeding 5 ft-lbs; M8 screws can handle up to 30 ft-lbs.

- Use a torque wrench to prevent over-tightening, which can strip threads or deform the shoulder.

3. Thread Locking

For high-vibration applications, applythread-locking compound (par ex., Loctite) to prevent loosening. Avoid over-application, as excess can seep into the shoulder area.

4. Tools Needed

- Hex keys or Allen wrenches (match drive size A/F from the table above).

- Torque wrench for precision applications.

- Thread tap and drill bits for hole preparation.

Maintenance and Corrosion Prevention

Stainless steel resists corrosion, but proper care extends lifespan:

- Cleaning: Use mild soap and water; avoid abrasive cleaners that damage the passive chromium oxide layer.

- Lubrication: Apply dry lubricant (par ex., graphite) to the shoulder if used in sliding applications to reduce wear.

- Inspection: Check for loosening quarterly in high-vibration environments. Replace if threads show damage or corrosion.

- Stockage: Keep unused screws in dry, sealed containers to prevent moisture exposure.

Sourcing and Cost Considerations

When sourcing stainless shoulder screws, consider these factors:

1. Suppliers and Certification

Choose suppliers offering ISO 7379-compliant products with RoHS certification (ensures no hazardous substances). Reputable suppliers include industrial distributors and specialized fastener companies.

2. Quantity Discounts

Bulk orders reduce per-unit costs significantly:

- 1–99 pieces: ~$4.99 each (for M3 size)

- 100–249 pieces: ~$4.57 each

- 250–499 pieces: ~$4.16 each

- 500+ pièces: ~$3.74 each

3. Custom Orders

For non-standard sizes (par ex., unique shoulder lengths or threads like 4-40), request quotes from manufacturers with in-house machining capabilities. Lead times typically range from 2–4 weeks.

4. CAD Resources

Top suppliers provide STEP files or CAD models for download, simplifying design integration. Most offer email delivery of CAD files for quick access.

Yigu Technology’s Perspective

Stainless shoulder screws are unsung heroes in precision engineering. Chez Yigu Technologie, we trust their ability to deliver consistent alignment and corrosion resistance across industries. By adhering to ISO standards and choosing the right grade, engineers can ensure reliability in everything from medical devices to automotive systems. Smart sourcing and proper installation maximize their performance and value.

FAQ

- What’s the difference between a shoulder screw and a regular screw?

A shoulder screw has an unthreaded shoulder (larger than the thread diameter) for alignment/spacing, while regular screws have uniform threading or a smaller head with no shoulder. - Can stainless shoulder screws be used outdoors?

Oui, AISI 304 works in mild outdoor environments, but for saltwater or high humidity, use AISI 316 for superior corrosion resistance. - How do I choose the right shoulder length?

Measure the thickness of the material needing spacing; the shoulder length should match this dimension to ensure proper alignment.