Si vous recherchez « Tôle Portugal,« vous cherchez probablement à vous associer à un fabricant de tôle fiable, s'approvisionner en composants de haute qualité, ou comprendre le rôle du pays dans le secteur métallurgique européen. La bonne nouvelle est que l’industrie portugaise de la tôlerie se distingue par son combinaison d'expertise technique, prix compétitif, et le respect des normes de qualité de l'UE— ce qui en fait un choix de premier ordre pour les entreprises du secteur automobile, aérospatial, et secteurs industriels. Dans ce guide, nous allons détailler tout ce que vous devez savoir, des principaux atouts du secteur à la manière de choisir le bon partenaire, et même les tendances futures qui façonnent sa croissance.

1. L'état de l'industrie de la tôle au Portugal: Faits et chiffres clés

Le secteur de la tôlerie portugaise est un élément essentiel de son économie manufacturière, contribuant de manière significative aux exportations et à l’emploi. Pour comprendre sa valeur, commençons par les données concrètes et les principaux atouts qui le distinguent.

Points forts de l'industrie

- Conformité UE: Tous les fabricants portugais de tôlerie respectent les réglementations européennes strictes., y compris REACH (pour la sécurité chimique) et marquage CE (pour la sécurité des produits). Cela élimine les risques de non-conformité pour les entreprises vendant en Europe..

- Main-d'œuvre qualifiée: Le Portugal investit dans des programmes de formation professionnelle pour les métallurgistes, avec des institutions comme Institut de Formation Professionnelle et d'Emploi (IFPE) offrir des cours spécialisés en fabrication de tôle, soudage, et fonctionnement CNC.

- Axé sur l'exportation: Sur 60% de la production de tôle du Portugal est exportée, principalement vers d'autres pays de l'UE (Espagne, France, Allemagne) et les marchés mondiaux comme les États-Unis et le Brésil. Cela signifie que les fabricants sont expérimentés dans la logistique internationale et dans les besoins des clients..

Statistiques clés (2024 Estimations)

| Métrique | Valeur | Source |

| Nombre de fabricants de tôles | 800+ | Association portugaise de l'industrie métallurgique, Mécanique et Matériaux (APIMEC) |

| Chiffre d'affaires de l'industrie | 2,3 milliards d'euros | Rapport annuel APIMEC 2023 |

| Emploi dans le secteur | 28,000+ ouvriers | Ministère portugais de l'Économie |

| Premier marché d’exportation | Espagne (32% des exportations) | Eurostat |

Exemple concret: Une histoire de réussite

Prendre Fernandes Metalúrgica, une entreprise familiale de tôlerie basée à Porto. Fondée en 1985, il a commencé comme un petit atelier mais fournit désormais des composants en tôle à de grandes marques automobiles comme Volkswagen et Renault. Leur succès réside dans la combinaison de l'artisanat traditionnel avec la technologie CNC moderne, ce qui leur permet de produire des pièces complexes avec des tolérances serrées. (aussi bas que ±0,1 mm). Cet exemple montre comment les entreprises portugaises de tôlerie évoluent tout en maintenant la qualité., un trait commun dans l'industrie.

2. Pourquoi choisir les fabricants de tôle au Portugal?

Vous pourriez vous demander: avec d'autres pays européens (comme l'Allemagne ou l'Italie) connu pour la fabrication, pourquoi choisir le Portugal? La réponse réside dans un équilibre unique de qualité, coût, et une flexibilité qui répond aux besoins des petites et moyennes entreprises (PME) et les grandes entreprises.

Compétitivité des coûts sans sacrifier la qualité

Le Portugal offre des coûts de main-d'œuvre et d'exploitation inférieurs à ceux des pays d'Europe occidentale comme l'Allemagne ou la Suède, généralement 15-25% inférieur pour des prestations de tôlerie équivalentes. Cela ne veut pas dire rogner sur les raccourcis: la plupart des fabricants utilisent des équipements de pointe (par ex., découpeuses laser à fibre, bras de soudage robotisés) pour assurer la précision. Par exemple, une entreprise allemande se procurant un lot de supports en tôle pourrait payer 12 € par unité auprès d'un fournisseur local, mais 9 € l'unité chez un fabricant portugais – avec le même ISO 9001 attestation.

Flexibilité pour les petites et grandes commandes

Contrairement à certains grands fabricants qui exigent des quantités minimales de commande (MOQ) de 1,000+ unités, de nombreuses entreprises portugaises de tôlerie répondent à des commandes plus petites (à partir de 50 unités). C'est idéal pour les startups ou les entreprises testant de nouveaux produits. Par exemple, TôlerieLisbonne, un fabricant dans la capitale, se spécialise dans la production de prototypes et de faibles volumes, aidant une startup basée au Royaume-Uni à créer 100 boîtiers en tôle personnalisés pour leur nouvel appareil IoT en seulement 2 semaines.

Proximité des principaux marchés européens

La situation du Portugal (sur la côte sud-ouest de l’Europe) signifie une expédition rapide vers les marchés clés. Par exemple:

- Expédition à Madrid (Espagne) prend 1-2 jours de route.

- Expédition à Paris (France) prend 3-4 jours par route ou par train.

- Fret aérien vers Berlin (Allemagne) prend 24 heures.

Cela réduit les délais de livraison et les coûts logistiques, un facteur critique pour les entreprises ayant des calendriers de production serrés.

3. Processus et capacités clés de la tôlerie au Portugal

Les fabricants portugais proposent une gamme complète de services de tôlerie, de la conception à la finition. Comprendre ces capacités vous aidera à trouver un partenaire qui correspond aux besoins de votre projet.

Processus courants de tôlerie

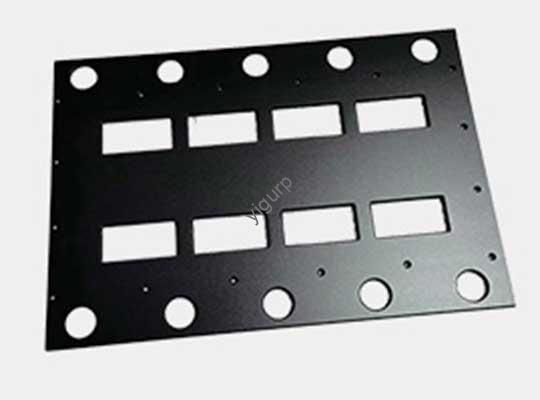

- Découpe Laser: La plupart des entreprises utilisent des découpeuses laser à fibre, qui peut couper des métaux comme l'acier, aluminium, et acier inoxydable jusqu'à 25 mm d'épaisseur avec une haute précision. C’est idéal pour les formes complexes (par ex., pièces automobiles, coffrets électriques).

- Poinçonnage CNC: Utilisé pour la production de trous en grand volume, encoches, ou des formes simples. C’est plus rapide et plus rentable que la découpe laser pour les conceptions répétitives.

- Pliage et formage: Utiliser des presses plieuses CNC, les fabricants peuvent plier la tôle en angles (90°, 135°, etc.) ou des formes 3D. La longueur de flexion maximale varie généralement de 1,5 m à 3 m., en fonction de la machine.

- Soudage: Les méthodes courantes incluent MIG (Gaz inerte métallique) et TIG (Gaz inerte de tungstène) soudage. Le soudage robotisé est de plus en plus utilisé pour des raisons de cohérence, notamment dans les projets automobiles et aérospatiaux.

- Finition: Services comme le revêtement en poudre (disponible dans 100+ couleurs), galvanisation (pour la résistance à la corrosion), et sérigraphie (pour l'image de marque) sont largement proposés.

Capacités spécialisées pour les secteurs de niche

Certains fabricants se concentrent sur des industries de niche, offrant des services spécialisés:

- Aérospatial: Les fabricants aiment Aernnova Portugal (basé à Viseu) produire des composants en tôle pour avions, conforme aux normes strictes AS9100 (gestion de la qualité aérospatiale).

- Dispositifs médicaux: Des entreprises comme Metalúrgica Gomes créer des pièces en tôle pour équipement médical (par ex., lits d'hôpitaux, appareils de diagnostic) avec des finitions biocompatibles.

- Énergie renouvelable: Avec la poussée du Portugal en faveur de l’énergie éolienne et solaire, des entreprises comme Énergie Métal réaliser des structures en tôle pour éoliennes et panneaux solaires, conçu pour résister aux conditions météorologiques difficiles.

4. Comment choisir le bon partenaire de tôlerie au Portugal

Il est crucial de sélectionner un fabricant qui correspond aux objectifs de votre projet.. Suivez ces étapes pour prendre une décision éclairée.

Étape 1: Définissez les exigences de votre projet

Avant de contacter les fournisseurs, clarifier:

- Type de matériau (par ex., acier doux, aluminium, acier inoxydable) et épaisseur.

- Processus requis (par ex., découpe laser, flexion, soudage).

- Volume de commande (prototype, faible volume, grand volume).

- Normes de qualité (par ex., OIN 9001, AS9100, IATF 16949 pour l'automobile).

- Délai de mise en œuvre (à quelle vitesse vous avez besoin des pièces).

Étape 2: Vérifier les certifications et le contrôle qualité

Vérifiez toujours les certifications pertinentes. Les plus importants pour la tôle au Portugal sont:

- OIN 9001: Assure une gestion cohérente de la qualité.

- IATF 16949: Pour la fabrication spécifique à l'automobile (requis par des marques comme Ford ou Toyota).

- AS9100: Pour les composants aérospatiaux.

Demandez au fabricant de partager son contrôle qualité (QC) processus, par exemple, Est-ce qu'ils inspectent les pièces à chaque étape (coupe, flexion, soudage) ou seulement à la fin? Un partenaire fiable aura un plan de contrôle qualité documenté.

Étape 3: Évaluer l'expérience et les références

Recherchez un fabricant ayant de l'expérience dans votre secteur. Par exemple, si vous avez besoin de pièces en tôle pour une machine de transformation alimentaire, choisissez une entreprise qui a travaillé avec des clients de l’industrie alimentaire (ils comprendront les exigences telles que les nuances d'acier inoxydable et les conceptions faciles à nettoyer).

Demandez des références ou des études de cas. Un bon fournisseur se fera un plaisir de partager les coordonnées d'anciens clients. Contactez ces clients et demandez:

- Le fabricant a-t-il respecté les délais?

- Les pièces étaient-elles de qualité constante?

- Comment ont-ils géré les problèmes (par ex., dimensions incorrectes)?

Étape 4: Comparez les devis et les délais

Obtenez des devis de 2-3 fabricants. Ne vous contentez pas de choisir l’option la moins chère : tenez compte de facteurs tels que la qualité, expérience, et délai de livraison. Par exemple, un devis légèrement plus élevé d'un fabricant avec des délais de livraison plus rapides pourrait en valoir la peine si vous avez besoin de pièces de toute urgence.

Assurez-vous que le devis inclut tous les coûts (par ex., matériel, travail, finition, expédition) pour éviter des frais cachés plus tard.

5. Les tendances futures qui façonnent l’industrie de la tôle au Portugal

Pour rester en tête, il est important de comprendre les tendances qui animent l’industrie. Voici les principaux développements à surveiller:

1. Automatisation et Industrie 4.0

De plus en plus de fabricants portugais de tôles adoptent l'automatisation et l'industrie 4.0 technologies. Cela comprend:

- Bras robotiques: Utilisé pour le soudage, manutention des matériaux, et assemblage : réduction des erreurs humaines et augmentation de la vitesse de production.

- Technologie de jumeau numérique: Créer une copie virtuelle du processus de production pour tester les conceptions et optimiser l'efficacité avant la production physique.

- Capteurs IoT: Installé sur les machines pour surveiller les performances et prévoir les besoins de maintenance (par ex., un capteur sur une découpeuse laser peut alerter l'équipe lorsqu'une pièce doit être remplacée, éviter les temps d'arrêt inattendus).

Par exemple, MetalTech Porto a récemment investi 500 000 € dans des bras de soudage robotisés, réduisant les délais de production des pièces automobiles en 30% tout en améliorant la qualité des soudures.

2. Durabilité et fabrication verte

Le Portugal s'engage à réduire les émissions de carbone, et l'industrie de la tôlerie emboîte le pas. Les principales pratiques durables comprennent:

- Matériaux recyclés: Utiliser de l'acier et de l'aluminium recyclés (utilisations de l'aluminium recyclé 95% moins d'énergie à produire que l'aluminium vierge).

- Machines économes en énergie: Les nouvelles découpeuses laser et presses plieuses sont conçues pour consommer moins d'électricité.

- Réduction des déchets: Optimiser l'imbrication (le processus de disposition des pièces sur une feuille de métal) pour minimiser les rebuts. Certains fabricants atteignent désormais des taux de rebut aussi bas que 5% (vers le bas de 10-15% il y a dix ans).

- Finitions respectueuses de l'environnement: Utilisation de revêtements en poudre à faible teneur en COV (composé organique volatil) émissions.

De nombreux fabricants recherchent également OIN 14001 attestation (gestion environnementale), ce qui démontre leur engagement en faveur du développement durable.

3. Croissance des énergies renouvelables et des véhicules électriques (VÉ)

L’accent du Portugal sur les énergies renouvelables (il vise à être neutre en carbone en 2050) et la transition mondiale vers les véhicules électriques créent de nouvelles opportunités pour l'industrie de la tôle.. La demande augmente pour:

- Structures en tôle pour éoliennes (par ex., sections de tour, enceintes de nacelles).

- Composants pour panneaux solaires (par ex., cadres, systèmes de montage).

- Pièces pour véhicules électriques (par ex., boîtiers de batterie, composants du châssis).

L'APIMEC prédit que les secteurs des énergies renouvelables et des véhicules électriques entraîneront une 12% croissance de la demande de tôle au Portugal de 2026.

6. Le point de vue de Yigu Technology sur la tôlerie au Portugal

Yigu Technology reconnaît le Portugal comme un acteur remarquable dans le paysage européen de la tôlerie, grâce à son mélange unique de qualité, rentabilité, et adaptabilité. Ce qui distingue le Portugal, c'est sa capacité à servir à la fois les petites et les grandes entreprises, en offrant de faibles MOQ aux startups tout en ayant la taille nécessaire pour répondre aux besoins des géants de l'automobile ou de l'aérospatiale.. L’accent mis par l’industrie sur la durabilité et l’industrie 4.0 s'aligne également sur les tendances manufacturières mondiales, ce qui en fait un partenaire avant-gardiste pour les entreprises qui souhaitent réduire leur empreinte carbone et améliorer leur efficacité. Pour les entreprises cherchant à s’approvisionner en tôle en Europe, Le Portugal n’est pas seulement une option économique, c’est un choix stratégique qui équilibre la fiabilité, compétence, et préparation pour l'avenir.

FAQ: Questions courantes sur la tôlerie au Portugal

1. Avec quels types de métaux les fabricants de tôles portugais travaillent-ils ??

La plupart des fabricants manipulent une gamme de métaux, y compris l'acier doux (le plus courant), aluminium (léger et résistant à la corrosion), acier inoxydable (idéal pour la nourriture, médical, ou applications extérieures), et du cuivre (utilisé dans les composants électriques). Certains travaillent également avec des métaux spéciaux comme le titane pour des projets aérospatiaux.

2. Combien de temps faut-il pour obtenir des pièces en tôle du Portugal?

Les délais de livraison dépendent du volume et de la complexité des commandes. Pour prototypes ou petites commandes (50-100 unités), tu peux t'attendre 1-2 semaines. Pour les commandes à gros volume (1,000+ unités), les délais de livraison sont généralement 3-4 semaines. L'expédition vers d'autres pays de l'UE ajoute 1-4 jours, en fonction de la destination.

3. Les fabricants portugais proposent-ils une assistance à la conception?

Oui, beaucoup fournissent la conception pour la fabrication (DFM) soutien. Leurs ingénieurs peuvent examiner vos modèles ou dessins 3D pour suggérer des améliorations permettant de réduire les coûts ou d'améliorer l'efficacité de la production. (par ex., changer une forme complexe pour faciliter la découpe au laser).

4. Les pièces en tôle portugaise sont-elles conformes à la réglementation européenne?

Absolument. Tous les fabricants réputés suivent les normes de l'UE, y compris le marquage CE (pour la sécurité des produits), ATTEINDRE (pour les restrictions chimiques), et des normes industrielles spécifiques comme l'IATF 16949 (automobile) ou AS9100 (aérospatial). Ils peuvent fournir des documents pour prouver la conformité.

5. Puis-je visiter une usine de tôlerie portugaise avant de passer une commande?

La plupart des fabricants acceptent les visites d'usine, surtout pour les projets de grande envergure ou à long terme. Cela vous permet de voir leur équipement, processus de contrôle de qualité, et les conditions de travail. Beaucoup proposent également des visites virtuelles si vous ne pouvez pas voyager en personne.