Sheet metal processing services for prototype Custom

Yigu provides sheet metal prototype to small to medium batch production suppliers, with ISO 9001:2015 certified factories, offering a diverse range of sheet metal processing services to meet the needs of various projects, from simple bent sheet metal prototypes to complex mechanical assemblies. You can obtain standard parts in the shortest 3 jours.

What is sheet metal prototype?

Sheet metal prototype customization is a professional service that focuses on customizing prototypes for sheet metal parts. Through advanced sheet metal processing technologies such as laser cutting, estampillage, flexion, Tonte etc., samples that meet design requirements can be quickly and accurately manufactured. This service is commonly used to verify product design, test component compatibility, and conduct functional testing. The production process of sheet metal prototype is flexible and customized, and different materials, épaisseur, and surface treatment methods can be selected according to customer needs. This helps customers identify problems, optimize designs, and reduce production costs in the early stages of product development. By customizing sheet metal prototypes, customers can quickly obtain high-quality samples, providing strong support for product development.

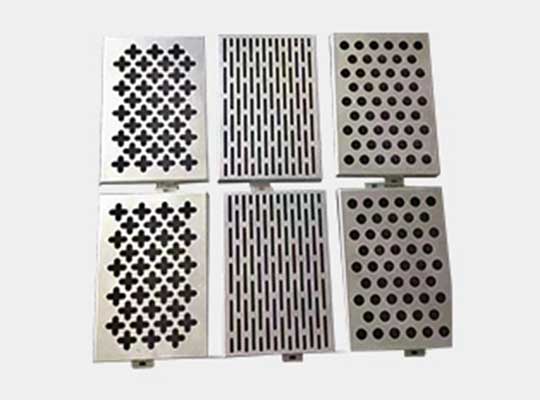

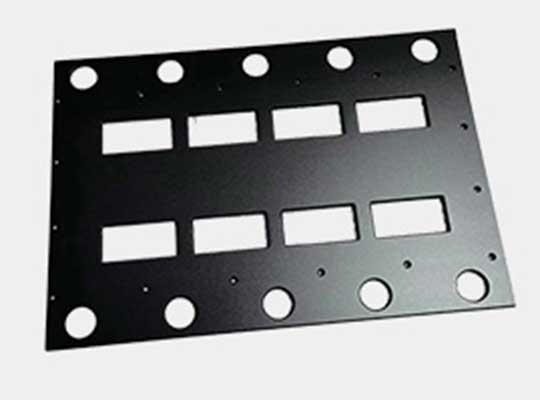

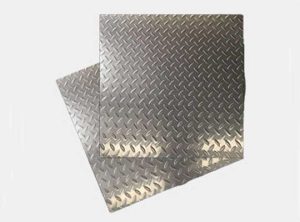

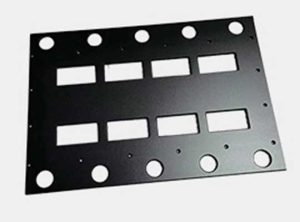

Sheet Metal Prototype and Parts Display

Les produits affichés ci-dessous ont été approuvés par le client, Et nous respectons strictement l'accord de confidentialité pour protéger la confidentialité et la créativité du client.

Material selection for Sheet Metal

Surface treatment for sheet metal processing

Oxydation: Anodisation, hard anodizing, conductive anodizing

Pulvérisation: sable, pulvérisation d'huile, powder spraying

Électroplaste: chrome, zinc, black zinc, or, argent, black nickel, étain, nickel, black chromium, decorative chromium

Autre: impression d'écran en soie, marquage laser, noircissement, tirage, electrolytic polishing, passivation

Complete your Sheet Metal prototype custom in 5 mesures

Pourquoi nous choisir?

Advantages of Sheet Metal Fabrication

Yigu provides an economical and efficient option for manufacturing metal components.

We can easily shape metals into various shapes, tailles, and thicknesses, and also provide

Multiple customization options, including different surface treatment methods such as anodizing and powder coating.

Sheet metal Fabrication application

Industrie automobile: corps, chassis, and other components.

Industrie: fuselage, composants structurels, fixed devices.

Electronic and medical industries: computer electronic product casings, châssis et pièces, supports, armoires.