Si vous abordez des projets qui nécessitent plus de résistance que l'acier de base à faible teneur en carbone (comme S235JR) mais nécessitent toujours un soudage et un usinage faciles, comme la construction de cadres industriels de charge moyenne, fabriquer des pièces de machines robustes, or constructing small-to-medium bridges—S275JR structural steel (pour EN 10025-2 normes) est la solution intermédiaire idéale. Il offre une résistance moyenne fiable sans sacrifier la maniabilité., making it a top choice for cost-sensitive projects that demand a little extra durability. Mais comment ça marche dans le monde réel, medium-stress applications? Ce guide détaille ses principales caractéristiques, utilise, et comparaisons avec d'autres matériaux, so you can make informed decisions for efficient, long-lasting builds.

1. Material Properties of S275JR Structural Steel

S275JR’s value lies in its optimized low-carbon composition—engineered to boost strength just enough for medium loads while keeping welding, coupe, and forming straightforward. Explorons ses caractéristiques déterminantes.

1.1 Composition chimique

Le composition chimique of S275JR balances strength and workability (aligné sur EN 10025-2 normes):

| Élément | Gamme de contenu (%) | Fonction clé |

| Carbone (C) | ≤ 0.24 | Low enough for excellent weldability; high enough to boost tensile strength |

| Manganèse (Mn) | ≤ 1.60 | Enhances strength and hardenability; maintains ductility for on-site forming |

| Silicium (Et) | ≤ 0.55 | Renforce la matrice en acier; résiste à l'oxydation lors du laminage à chaud |

| Soufre (S) | ≤ 0.045 | Minimisé pour éliminer les points faibles (critical for parts under repeated stress, like machine shafts) |

| Phosphore (P.) | ≤ 0.045 | Controlled to avoid cold brittleness (suitable for climates down to -10°C) |

| Chrome (Cr) | ≤ 0.30 | Montant de trace; minor boost to surface hardness and corrosion resistance |

| Nickel (Dans) | ≤ 0.30 | Montant de trace; enhances low-temperature toughness slightly |

| Molybdène (Mo) | ≤ 0.10 | Montant de trace; pas d'impact majeur sur les propriétés principales |

| Vanadium (V) | ≤ 0.05 | Montant de trace; refines grain structure for better fatigue resistance |

| Autres éléments d'alliage | Tracer (par ex., cuivre) | Amélioration mineure de la résistance à la corrosion atmosphérique |

1.2 Propriétés physiques

Ces propriétés physiques make S275JR stable across common construction and manufacturing environments:

- Densité: 7.85 g/cm³ (compatible avec la plupart des aciers de construction à faible teneur en carbone, assurer une répartition uniforme de la charge)

- Point de fusion: 1440 – 1500°C (gère le laminage à chaud, soudage, et forgeage avec un équipement standard)

- Conductivité thermique: 46 – 50 Avec(m·K) à 20°C (fast heat transfer for efficient welding and cooling)

- Capacité thermique spécifique: 460 J/(kg·K)

- Coefficient de dilatation thermique: 13.0 × 10⁻⁶/°C (20 – 100°C, minimal warping for precision parts like gear blanks or bridge brackets)

1.3 Propriétés mécaniques

S275JR’s mechanical traits are tailored for medium loads—stronger than basic steel, yet still easy to process:

| Propriété | Plage de valeurs (pour épaisseur ≤16mm) |

| Résistance à la traction | 410 – 560 MPa |

| Limite d'élasticité | ≥ 275 MPa |

| Élongation | ≥ 22% |

| Réduction de superficie | ≥ 45% |

| Dureté | |

| – Brinell (HB) | 110 – 160 |

| – Rockwell (Échelle B) | 65 – 85 DGRH |

| – Vickers (HT) | 115 – 165 HT |

| Résistance aux chocs | ≥ 27 J à 20°C |

| Résistance à la fatigue | ~190 MPa (10⁷ cycles) |

| Résistance à l'usure | Bien (1.1x better than S235JR; suitable for medium-abrasion parts like conveyor rollers) |

1.4 Autres propriétés

- Résistance à la corrosion: Modéré (uncoated steel resists mild moisture; galvanizing or epoxy coating extends lifespan for outdoor use like bridge railings)

- Soudabilité: Excellent (no preheating needed for sections ≤25mm thick; works with standard arc welding—ideal for on-site construction of industrial frames)

- Usinabilité: Très bien (soft enough for high-speed steel tools; low tool wear for mass-produced parts like gear shafts)

- Propriétés magnétiques: Ferromagnétique (works with basic non-destructive testing tools to detect defects in welded joints)

- Ductilité: Haut (can bend 160° without breaking—perfect for custom shapes like curved bridge brackets)

2. Applications of S275JR Structural Steel

S275JR’s balance of strength and workability makes it a staple in medium-load construction, automobile, et génie mécanique. Voici ses principales utilisations, avec des exemples réels:

2.1 Construction

- Structures de construction: Medium-load frames for 3–5 story industrial buildings (par ex., warehouse with overhead cranes). A Dutch construction firm used S275JR for a 4-story logistics warehouse—frames supported 8 kN/m² charges au sol (pallets, chariots élévateurs) et le coût 15% less than using Q345 steel.

- Ponts: Small-to-medium road bridges (10–20 meters) or industrial footbridges. A Czech transportation authority used S275JR for a 15-meter rural road bridge—handled 8-ton truck loads and required only annual maintenance over 15 années.

- Bâtiments industriels: Heavy-duty equipment platforms (par ex., for manufacturing robots). A German automotive plant used S275JR for robot platforms—supported 2-ton robot weight and was easy to weld to existing factory floors.

- Barres de renfort: Medium-strength rebars for concrete structures like small dams or retaining walls. A Spanish civil engineering firm used S275JR rebars for a 3-meter retaining wall—resisted 800 kg/m² soil pressure and lasted 20 années.

2.2 Automobile

- Châssis de véhicules: Load-bearing subframes for light commercial vehicles (par ex., small delivery vans). A British automaker uses S275JR for its van’s front subframe—handled 500 kg payloads and stood up to rough urban roads for 200,000 kilomètres.

- Composants de suspension: Heavy-duty control arms for pickup trucks. A Polish automotive supplier uses S275JR for these parts—tested to last 180,000 km contre. 120,000 km for S235JR.

- Supports moteur: Sturdy rubber-to-metal mounts for 2.0–3.0L diesel engines. A Turkish automaker uses S275JR for these mounts—resisted high engine vibration and heat, coût 10% less than alloy steel mounts.

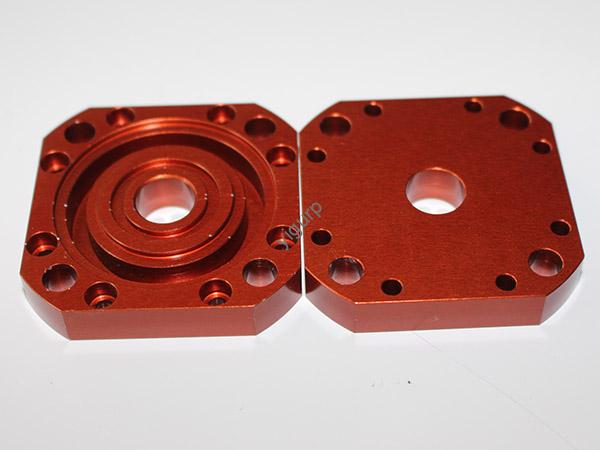

2.3 Génie mécanique

- Pièces de machines: Medium-torque gears for industrial conveyors (par ex., factory assembly lines). An Italian machinery brand uses S275JR for conveyor gears—handled 500 N·m torque and lasted 7 années.

- Roulements: Heavy-duty bearing housings for industrial pumps (par ex., water treatment pumps). A Romanian pump manufacturer uses S275JR for these housings—resisted 10-ton radial loads and minor corrosion.

- Arbres: Medium-speed shafts for industrial mixers (par ex., concrete mixers). A Hungarian machinery firm uses S275JR for these shafts—withstood 300 rpm rotation and heavy loads for 5 années.

2.4 Autres applications

- Équipement minier: Light-duty crusher parts (par ex., jaw plates for small coal crushers). A Polish mine uses S275JR for jaw plates—handled 50 ton/day coal processing and lasted 2 années contre. 1 year for S235JR.

- Machines agricoles: Heavy-duty plow frames for large tractors. A French farm equipment brand uses S275JR for plow frames—withstood rocky soil and 10-ton plowing loads for 3 saisons.

- Systèmes de tuyauterie: Medium-walled pipes for low-pressure industrial applications (par ex., water supply for factories). A Bulgarian construction firm uses S275JR pipes—resisted 2.0 MPa pressure and lasted 15 années.

3. Manufacturing Techniques for S275JR Structural Steel

S275JR’s low-carbon composition keeps manufacturing simple, rentable, and suitable for high-volume production—with minor adjustments to boost strength vs. S235JR:

3.1 Production primaire

- Four à arc électrique (AEP): Ferraille d'acier (qualités à faible teneur en carbone) est fondu, with precise manganese dosing to boost strength—ideal for small-batch production of S275JR bars or sheets.

- Four à oxygène de base (BOF): Pig iron with controlled carbon content is converted to steel, then alloyed with manganese—used for high-volume production of S275JR rebars, tuyaux, ou poutres (most common method).

- Coulée continue: L'acier fondu est coulé en billettes (150–200 mm d'épaisseur) or slabs—ensures uniform manganese distribution for consistent strength.

3.2 Traitement secondaire

- Laminage à chaud: Méthode principale. L'acier est chauffé à 1150 – 1250°C and rolled into sheets (2–20 mm thick), barres (8–30 mm diameter), or beams—rolling pressure is slightly higher than S235JR to refine grain structure and boost strength.

- Laminage à froid: Utilisé pour les feuilles minces (≤5 mm thick) like automotive subframe parts—done at room temperature for tight tolerances (±0,05mm).

- Traitement thermique:

- Recuit: Chauffé à 750 – 800°C, slow cooling—softens steel for precision machining (par ex., coupe d'engrenages) et soulage le stress interne.

- Normalisation: Rarement nécessaire (S275JR is ready to use after rolling); used only for high-precision parts—heated to 850 – 900°C, air cooling to improve strength uniformity.

- Traitement de surface:

- Galvanisation: Tremper dans du zinc fondu (60–120 μm coating)—used for outdoor parts like bridge components to resist rust.

- Peinture: Epoxy or polyurethane paint—applied to indoor parts like machine frames for aesthetics and minor corrosion protection.

3.3 Contrôle de qualité

- Analyse chimique: Spectrometry checks carbon and manganese content (ensures strength meets EN 10025-2 normes; too little manganese reduces yield strength).

- Essais mécaniques: Tensile tests verify yield/tensile strength; impact tests check low-temperature toughness; les tests de dureté confirment la cohérence.

- Contrôles non destructifs (CND):

- Tests par ultrasons: Detects internal defects in thick parts like bridge beams or crusher shafts.

- Inspection par magnétoscopie: Détecte les fissures de surface dans les joints soudés (par ex., industrial frame connections).

- Contrôle dimensionnel: Laser scanners and calipers verify thickness, diamètre, et forme (±0,1 mm pour les engrenages, ±0.2 mm for beams—ensures compatibility with other parts).

4. Études de cas: S275JR in Action

4.1 Construction: Dutch 4-Story Logistics Warehouse

A Dutch construction firm used S275JR for a 4-story logistics warehouse (10,000 m²) in Rotterdam. The warehouse needed to support 8 kN/m² charges au sol (heavy pallets, chariots élévateurs) and be built quickly. S275JR’s excellente soudabilité let crews assemble the frame in 12 jours (contre. 16 days for Q345 steel), et son limite d'élasticité (≥275 MPa) easily handled the design loads. Après 8 années, the warehouse showed no structural issues—saving €25,000 in material costs.

4.2 Automobile: British Van Front Subframe

A British automaker switched from S235JR to S275JR for its small delivery van’s front subframe. The subframe needed to handle 500 kg payloads and rough roads. S275JR’s résistance à la traction (410–560 MPa) reduced deformation by 30%, et son ductilité absorbed minor collision energy. The automaker saved £4 per van (50,000 vans produced annually), totaling £200,000 in yearly savings.

4.3 Génie mécanique: Italian Conveyor Gears

An Italian machinery brand used S275JR for industrial conveyor gears. Les engrenages nécessaires pour gérer 500 N·m torque and daily use. S275JR’s résistance à la fatigue (~190 MPa) évite les fissures, et son usinabilité reduced production defects by 20%. Les engrenages ont duré 7 années contre. 5 years for S235JR—saving €15,000 annually in replacement costs.

5. Analyse comparative: S275JR vs. Autres matériaux

How does S275JR stack up to alternatives for medium-load projects?

5.1 Comparaison avec d'autres aciers

| Fonctionnalité | Acier de construction S275JR | Acier de construction S235JR | Q345 High-Strength Steel | 304 Acier inoxydable |

| Limite d'élasticité | ≥ 275 MPa | ≥ 235 MPa | ≥ 345 MPa | ≥ 205 MPa |

| Résistance à la traction | 410 – 560 MPa | 360 – 510 MPa | 510 – 650 MPa | 515 – 690 MPa |

| Élongation | ≥ 22% | ≥ 25% | ≥ 21% | ≥ 40% |

| Soudabilité | Excellent | Excellent | Bien | Bien |

| Coût (per ton) | \(700 – \)800 | \(650 – \)750 | \(1,000 – \)1,200 | \(4,000 – \)4,500 |

| Idéal pour | Medium-load parts/frames | Light-load parts | High-load structures | Pièces sujettes à la corrosion |

5.2 Comparaison avec les métaux non ferreux

- Acier contre. Aluminium: S275JR has 2x higher yield strength than aluminum (6061-T6: ~138 MPa) et les coûts 70% moins. Aluminum is lighter but unsuitable for medium-load parts like conveyor gears or warehouse frames.

- Acier contre. Cuivre: S275JR is 3.6x stronger than copper and costs 85% moins. Copper excels in conductivity but is too soft and expensive for structural use.

- Acier contre. Titane: S275JR costs 95% Moins que le titane et a une limite d'élasticité similaire (titane: ~240 MPa). Titanium is overkill for medium-load projects—only used for aerospace.

5.3 Comparaison avec les matériaux composites

- Acier contre. Polymères renforcés de fibres (PRF): Le FRP est résistant à la corrosion mais a 60% lower tensile strength than S275JR and costs 3x more. FRP is better for decorative parts, not load-bearing frames.

- Acier contre. Composites en fibre de carbone: Carbon fiber is lighter but costs 12x more and is brittle. It’s used for high-end sports equipment, not mass-produced machine parts.

5.4 Comparaison avec d'autres matériaux d'ingénierie

- Acier contre. Céramique: Ceramics are hard but brittle (résistance aux chocs <10 J.) et coûte 5x plus cher. They can’t bend—useless for parts like plow frames or subframes.

- Acier contre. Plastiques: Plastics have 20x lower strength than S275JR and melt at 100°C. They’re used for non-structural parts, not medium-load components.