Dans le secteur de la robotique en plein développement, vérifier la faisabilité et la fonctionnalité de la conception dès le début est essentiel pour éviter des erreurs coûteuses dans la production de masse. Le prototype model of the soft rubber robot is a game-changer—it lets engineers test flexible parts, simuler des conditions de travail réelles, et collecter des données fiables à moindre coût. Whether you’re a procurement engineer selecting materials or a product engineer refining a robot’s design, this guide covers everything you need to create high-quality soft rubber robot prototypes.

1. Why Soft Rubber Materials Are Ideal for Robot Prototypes

Robots often work in varied environments—from factories with high temperatures to labs needing corrosion resistance—and their flexible parts (like grippers or gaskets) need to perform reliably. Soft rubber materials meet these demands, making them perfect for robot prototypes.

Below is a detailed breakdown of common soft rubber materials, leurs propriétés, and real robot application cases to help you choose wisely:

| Type de matériau | Propriétés clés | Robot Use Case Example | Temperature Resistance Range |

| TPU (Polyuréthane thermoplastique) | Excellente résistance à l'usure, high elasticity, strong tear resistance | Flexible grippers for industrial robots (to handle fragile items) | -40°C à 120°C |

| Caoutchouc de silicone | Superior high-temperature resistance, inertie chimique, facile à nettoyer | Sealing gaskets for medical robots (to resist disinfectants) | -60°C à 230°C |

| EPDM (Ethylene Propylene Rubber) | Strong water and ozone resistance, long-lasting flexibility | Protective sleeves for outdoor robot cables (to withstand weather) | -50°C à 150°C |

Étude de cas: A leading industrial robot brand used TPU prototypes to test flexible grippers for picking glass panels. The prototypes went through 5,000+ gripping cycles without tearing, proving the design’s durability. This early test saved the brand $150,000 in potential rework costs for mass-produced grippers.

2. Step-by-Step Process to Make the Prototype Model of the Soft Rubber Robot

Creating a reliable prototype model of the soft rubber robot requires strict adherence to precise steps. Below is a proven workflow used by top robotics manufacturers:

Étape 1: Material Selection – Choose the Right Foundation

Picking the correct material is critical—it directly impacts the prototype’s performance. When selecting, ask these key questions:

- Will the part handle high temperatures (like parts near robot motors)? Opt for silicone.

- Will it be exposed to water or chemicals (like medical robot components)? EPDM or silicone is a safe bet.

- Does it need to withstand frequent movement (like robot joints)? TPU’s wear resistance makes it ideal.

Pour un pourboire: A small robotics startup once chose EPDM instead of TPU for a robot joint prototype. The EPDM wore out after 1,000 cycles, causing a 4-week delay—always match the material to the part’s intended use!

Étape 2: Data Collection – Ensure Design Accuracy

This step lays the groundwork for a prototype that matches your exact design:

- 3D Drawing Import: Ask for customer-provided 3D CAD files (par ex., STEP or IGES formats). These files are the blueprint—importing them into computer software allows for precise data processing and machining programming. Par exemple, a warehouse robot maker once provided incomplete CAD files for a gripper prototype, leading to misaligned fingers; double-checking files upfront avoids such issues.

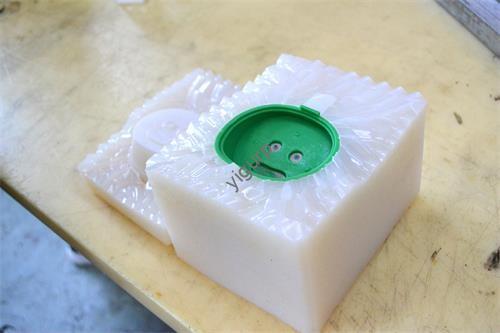

- Gypsum Sample Production: Create a gypsum sample based on the 3D drawings to confirm the part’s shape, curvature, and size. This is a “test run” for mold making—if the gypsum sample is inaccurate, the final prototype will be too. A medical robot manufacturer uses gypsum samples to verify the curve of a soft rubber gasket, ensuring a 0.1mm margin of error for a tight seal.

Étape 3: CNC Machining – Shape with Precision

CNC machining turns your chosen soft rubber material into the prototype with unmatched accuracy:

- Programmation & Setting: Use CNC software (comme Mastercam) to create cutting paths. The machine then removes excess rubber, retaining the exact shape of the robot part. CNC machining delivers a smooth surface (as low as Ra 0.8μm), which is essential for parts that need tight fits (like robot seal gaskets).

- Multi-Axis Machining Technology: Pour pièces complexes (par ex., a curved soft rubber gripper for a collaborative robot), use multi-axis CNC machines. This technology lets you machine complex shapes directly from rubber sheets or rods—no molds needed—and boosts precision by 30% par rapport à l'usinage traditionnel. A collaborative robot brand cut prototype production time from 6 jours pour 2.5 using this tech.

Étape 4: Post-Treatment – Enhance Durability & Esthétique

Post-treatment ensures your prototype is ready for testing and real-world use:

- Ébavurage: Use 400-grit or finer sandpaper to smooth knife marks and burrs on the prototype’s surface. Burrs can damage other robot components (par ex., a tiny burr on a gasket might scratch a robot’s internal parts)—this step is non-negotiable.

- Traitement de surface: Apply treatments like spray painting (for color coding), sérigraphie (for part labels), or electroplating (pour une résistance supplémentaire à la corrosion). A factory robot maker uses silk screen printing on soft rubber control buttons— the labels stay legible even after 10,000+ presses.

Étape 5: Assemblée & Testing – Verify Functionality

This step ensures your prototype works as intended in real robot operations:

- Test Assembly: Put all prototype parts together to check for gaps or misalignments. Par exemple, an automotive robot manufacturer tests assembling soft rubber gripper pads with metal claws to ensure no slipping during part handling.

- Tests fonctionnels: Test the assembled prototype under conditions that mimic real use. Key tests include:

- Structural stability: Subject the prototype to 10,000+ cycles vibratoires (simulating factory floors) sans fissures.

- Propriétés mécaniques: Measure tensile strength (TPU prototypes typically reach 50-70 MPa) to ensure they handle stress.

- Environmental simulation: Expose the prototype to -30°C to 180°C (covering most robot working environments) pour 200 hours with no deformation.

Étape 6: Conditionnement & Shipping – Protect Your Prototype

Your prototype is valuable—protect it during transport:

- Safe Packaging: Use foam inserts and hard plastic cases to prevent damage. A supplier once shipped prototypes in thin cardboard boxes; 25% of them got crushed, leading to project delays. Investing in quality packaging saves time and money.

- Délai de livraison: Align production with customer timelines. Most robotics projects need prototypes in 3-4 semaines. If there’s a delay (par ex., pénuries matérielles), communicate early to manage expectations.

3. Yigu Technology’s Perspective on the Prototype Model of the Soft Rubber Robot

Chez Yigu Technologie, we’ve supported 400+ robotics clients in creating prototype models of the soft rubber robot plus d'une décennie. We believe success lies in material customization and strict quality control. Par exemple, we developed a custom silicone blend for a medical robot client that resists strong disinfectants and stays flexible at -50°C—exceeding their requirements. We also use 3-stage testing (pré-usinage, post-treatment, final assembly) to meet ISO 9001 and robotics industry standards. For engineers and procurement teams, partnering with a supplier who understands robotics’ unique needs is essential to avoid costly errors.

FAQ

- Q: How long does it take to make a prototype model of the soft rubber robot?

UN: Typiquement 3-4 semaines, en fonction de la complexité. Pièces simples (like small gaskets) prendre 3 semaines, tandis que les pièces complexes (like multi-part grippers) prendre 4 semaines.

- Q: Can soft rubber robot prototypes be used for medical robot applications?

UN: Oui, si vous choisissez le bon matériau. Medical-grade silicone (répondant aux normes de la FDA) is often used for prototypes of medical robot parts, as it resists disinfectants and is non-toxic. Always confirm material certifications with your supplier.

- Q: Do you offer material samples before making the prototype?

UN: Absolument. Chez Yigu Technologie, we provide small samples of TPU, silicone, and EPDM. Testing samples first (pour la flexibilité, résistance à la température, etc.) helps you pick the right material and avoid prototype mistakes.