Si vous êtes un ingénieur produit ou un professionnel des achats travaillant sur le développement de produits, que ce soit pour des pièces automobiles, dispositifs médicaux, or industrial tools—prototype CNC machining is your go-to solution for turning design ideas into physical, modèles testables. Contrairement à l'usinage manuel, CNC (Commande numérique par ordinateur) utilise un code préprogrammé pour couper et façonner les matériaux avec une précision inégalée, making it ideal for validating designs before mass production. Ce guide détaille chaque étape du processus, key technical tips, exemples concrets, and data to help you get reliable prototypes efficiently.

1. What Is Prototype CNC Machining?

D'abord, let’s clarify the basics: Prototype CNC machining is a manufacturing process that uses computer-controlled machine tools to create small-batch prototypes or low-volume parts. It works by following digital designs (3D models) couper, tailler, or mill raw materials—like aluminum alloys, plastiques, or steel—into the exact shape of your product.

The core goal of this process is to:

- Test the form and fit of a design (par ex., does a new gear fit with existing components?).

- Validate fonctionnalité (par ex., can a medical device part withstand repeated use?).

- Identify design flaws early (par ex., weak spots in a bracket) to reduce costly changes later.

Why It Matters: A startup developing a portable power tool once used 3D printing for their first prototype. While the 3D-printed part looked right, it couldn’t handle the tool’s torque. Switching to prototype CNC machining with aluminum alloy gave them a functional prototype that revealed a need to strengthen the handle—saving them 3 months of rework in mass production.

2. Step-by-Step Prototype CNC Machining Process

The process has 5 étapes clés, each critical for ensuring your prototype meets design standards. Use the table in Stage 2.2 to match equipment to your project’s needs.

2.1 Conception & Programmation: Lay the Foundation

Avant usinage, you need a clear digital design and machine-readable code:

- 3Modélisation D: Use CAD software (par ex., SolidWorks, AutoCAD) to create a detailed 3D model of your prototype. Include exact dimensions (par ex., 100x50x5mm) et tolérances (par ex., ±0.05mm for precision parts).

- Programmation FAO: Convert the 3D model to CNC code (Code G) using CAM software (par ex., Mastercam, Fusion 360). This code tells the machine:

- Le cutting path (where the tool moves).

- Vitesse (how fast the tool spins).

- Vitesse d'alimentation (how fast the tool moves through the material).

Pro Tip: Pour pièces complexes (par ex., a prototype with holes and slots), add “toolpath simulations” in your CAM software. This lets you spot errors (like a tool crashing into the material) before machining—saving time and material.

2.2 Equipment Selection: Choose the Right CNC Machine

Not all CNC machines work for every prototype. Pick one based on your part’s complexity and material:

| CNC Machine Type | Principales fonctionnalités | Idéal pour |

| 3-Axe CNC | Se déplace le long de X, Oui, Axes Z; simple, rentable. | Basic prototypes (par ex., flat brackets, boîtiers en plastique). |

| 4-Axe CNC | Adds rotation around one axis (A-axis); handles parts with curved features. | Parts like gears, cylindrical housings. |

| 5-Axe CNC | Rotates around two axes (A et B); machines complex shapes from all angles. | Pièces de haute précision (par ex., composants aérospatiaux, implants médicaux). |

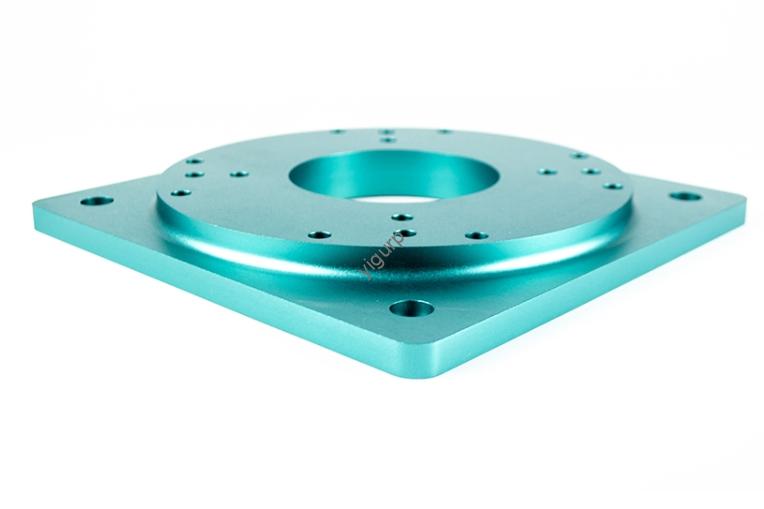

2.3 Sélection des matériaux & Fixation

Choose a material that matches your final product (to test real-world performance) and secure it to the machine to avoid shifting.

2.3.1 Top Materials for Prototype CNC Machining

| Matériel | Propriétés clés | Idéal pour |

| Alliage d'aluminium (6061-T6) | Léger (2.7 g/cm³), facile à usiner, fort. | Pièces automobiles, boîtiers d'outils. |

| Plastique ABS | Faible coût, résistant aux chocs, good for low-stress parts. | Boîtiers électroniques, consumer product prototypes. |

| Acier inoxydable (304) | Résistant à la corrosion, haute résistance (515 Résistance à la traction MPa). | Dispositifs médicaux, food-processing equipment. |

| Polycarbonate (PC) | Transparent, incassable, résistant à la chaleur (jusqu'à 135°C). | Visible parts (par ex., couvertures d'affichage, light fixtures). |

2.3.2 Material Fixation Tips

- Utiliser vacuum chucks for flat, thin materials (par ex., 2mm PC sheets)—they hold the material evenly without leaving marks.

- Pour les matériaux plus épais (par ex., 10mm aluminum blocks), utiliser soft-jaw clamps lined with rubber to prevent scratching.

2.4 Roughing & Finition: Shape Your Prototype

These two stages turn raw material into a precise prototype:

| Stage | Tools Used | Key Parameters | But |

| Roughing | Large end mills (10-16mm diamètre) | Cutting speed: 150-300 m/mon; Vitesse d'alimentation: 50-200 mm/min | Remove 70-90% of excess material quickly; leave 0.1-0.3mm for finishing. |

| Finition | Small end mills (2-6mm diamètre) | Cutting speed: 100-250 m/mon; Vitesse d'alimentation: 20-80 mm/min | Refine the part to meet exact dimensions and surface quality (Râ 0.8-1.6 µm). |

Étude de cas: A medical device company machining a stainless steel prototype skipped roughing and went straight to finishing. The small end mill took 4 hours to remove excess material and dulled halfway through—ruining the part. Adding roughing cut the total time to 1.5 hours and preserved the finishing tool.

2.5 Post-traitement & Contrôle qualité

Après usinage, prepare the prototype for testing and verify its quality:

- Post-traitement:

- Ébavurage: Use a deburring tool or 400-grit sandpaper to remove sharp edges (prevents injury during testing).

- Cleaning: Wipe the part with isopropyl alcohol (pour les plastiques) or a degreaser (pour les métaux) to remove cutting fluid.

- Traitement de surface (optional): Add anodization (pour l'aluminium) ou peinture (pour l'esthétique) si nécessaire.

- Contrôle qualité:

- Utilisez un caliper to check dimensions (par ex., diamètre du trou, longueur).

- Utilisez un coordinate measuring machine (MMT) for high-precision parts (ensures tolerance within ±0.01mm).

- Test functionality (par ex., for a prototype hinge, check if it opens and closes smoothly 100 times).

3. Advantages of Prototype CNC Machining

Why choose this process over 3D printing or manual machining? Here are the top benefits, backed by data:

- Haute précision & Répétabilité: CNC machines achieve tolerances as tight as ±0.005mm—far better than manual machining (±0,1mm). This means every prototype you make is identical, which is critical for testing consistency.

- Realistic Material Simulation: By using the same material as your final product (par ex., aluminum for a car part), you get accurate feedback on how the part will perform in real use. 3Impression D, par contre, often uses plastics that don’t match final material properties.

- Superior Surface Quality: Finishing stages produce smooth surfaces (Râ 0.8 µm) that meet high aesthetic standards—important for consumer products or visible parts.

- Large gamme d'applications: As shown in the table below, it’s used across key industries:

| Industrie | Common Prototype Uses |

| Automobile | Composants du moteur, parenthèses, pièces intérieures. |

| Médical | Surgical tool parts, implant prototypes, boîtiers d'appareils. |

| Dessin industriel | Consumer product shells (par ex., coques de téléphone), pièces de meubles. |

4. Limites & How to Overcome Them

Alors que prototype CNC machining is powerful, it has challenges—here’s how to address them:

- Coût & Vitesse: Prototypes complexes (par ex., 5-axis parts) can cost \(200-\)500 and take 3-5 jours.

Solution: Pour les pièces simples, use 3-axis CNC (frais 30% less than 5-axis) and order small batches (1-5 parties) to test designs before scaling.

- High Technical Requirements: Operating CNC machines and programming G-code needs skill.

Solution: Partner with a supplier (comme la technologie Yigu) that offers turnkey services—they handle design, programmation, and machining for you.

- Material Limitations: Some materials (par ex., soft rubbers) are hard to machine with CNC.

Solution: For flexible parts, combine CNC machining (for hard components) with 3D printing (for soft parts) to create hybrid prototypes.

Yigu Technology’s View on Prototype CNC Machining

Chez Yigu Technologie, we’ve supported 400+ clients in optimizing prototype CNC machining pour l'automobile, médical, et projets industriels. We believe the biggest mistake teams make is overcomplicating designs—adding unnecessary features that increase cost and machining time. Our solution: A “design for CNC” review service—we help simplify your 3D model (par ex., replacing complex curves with easier-to-machine shapes) without losing functionality. We also offer fast turnaround (2-3 days for 3-axis parts) and use high-precision CMM testing to ensure every prototype meets your specs. This cuts client R&D time by 25% on average.

FAQ

- How long does prototype CNC machining take?

It depends on complexity: A simple 3-axis plastic prototype (100x50x5mm) takes 1-2 jours. A complex 5-axis stainless steel part takes 3-5 jours (including design and inspection).

- Is prototype CNC machining more expensive than 3D printing?

Pour les petits, pièces simples (par ex., a 50x50x5mm plastic bracket), 3D printing is cheaper (\(30-\)50 contre. \(80-\)120 for CNC). But for large, pièces à haute résistance (par ex., aluminum automotive components), CNC is more cost-effective—3D printing would require expensive high-performance resins, making it 2x pricier.

- Can prototype CNC machining make parts with internal features (par ex., hollow channels)?

Yes—with 4-axis or 5-axis machines. Par exemple, we’ve machined aluminum prototype valves with internal flow channels (1mm diamètre) using 5-axis CNC. Just ensure your 3D model clearly shows internal features, and use a supplier with experience in complex machining.