Usinage de précision is the backbone of creating high-accuracy parts—think components that fit within tolerances as tight as ±0.001 mm. Que ce soit pour les moteurs aérospatiaux ou les dispositifs médicaux, chaque étape du processus exige un contrôle minutieux pour éviter des erreurs coûteuses. Ce guide détaille les étapes clés de l'usinage de précision, du choix des techniques aux applications concrètes, to help you produce consistent, pièces de haute qualité.

1. Techniques d'usinage: Choosing the Right Tool for the Job

Not all precision parts are made the same—your choice of machining technique depends on the part’s shape, matériel, and accuracy needs. Below’s a breakdown of the most common methods and their best uses:

| Technique | Comment ça marche | Idéal pour | Avantages clés |

| Tournant | Rotates the workpiece while a cutting tool shapes its outer/inner surface. | Pièces cylindriques (par ex., arbres, boulons). | Rapide, haute précision (up to ±0.002 mm), ideal for large batches. |

| Fraisage | Uses a rotating cutting tool to remove material from the workpiece. | Flat, formes complexes (par ex., engrenages, parenthèses). | Handles 2D/3D features; CNC milling adds automation. |

| Affûtage | Uses an abrasive wheel to smooth surfaces or tighten tolerances. | Finishing hardened parts (par ex., courses de roulements). | Surfaces ultra-lisses (Râ 0.02-0.8 µm); corrects small shape errors. |

| Forage | Creates holes with a rotating drill bit. | Simple holes (par ex., in electronic enclosures). | Fast and low-cost; works with most materials. |

| Usinage par électroérosion (GED) | Uses electrical sparks to erode material (no physical contact). | Hardened metals or complex shapes (par ex., mold cavities). | No tool wear; cuts intricate details impossible with turning/milling. |

| Laser Machining | Uses a high-energy laser to cut, graver, or drill. | Thin materials (par ex., cartes de circuits imprimés) or small features. | Non-contact (no workpiece damage); high speed for small parts. |

| Coupe de fil | A type of EDM—uses a thin wire (0.1-0.3 mm) to cut shapes. | Complex 2D parts (par ex., matrices d'estampage). | Tolérances serrées (±0,001 mm); cuts hard materials like tungsten. |

| Honing | Uses a rotating abrasive stone to finish internal surfaces (par ex., cylindres de moteur). | Improving hole roundness and surface finish. | Corrects minor misalignments; achieves Ra 0.1-0.4 µm. |

| Clapotis | Uses abrasive paste and a lapping plate to polish surfaces. | Optique (par ex., objectifs de caméra) or precision valves. | Finitions miroir (Râ <0.02 µm); extreme flatness. |

Quick Tip: For hardened steel parts (par ex., tool dies), use EDM or grinding—traditional turning/milling tools will wear out fast. Pour pièces en plastique, stick to milling or turning (laser may melt the material).

2. Machine Tools: The Foundation of Precision

The right machine tool makes or breaks precision. Modern tools rely on CNC (Commande numérique par ordinateur) for consistency, but choosing the correct type depends on your technique. Here’s what you need to know:

Core Machine Tools & Their Roles

- CNC Lathes: The workhorse for turning. CNC models (par ex., Haas ST-10) let you program complex cuts (par ex., cônes, fils de discussion) and repeat them perfectly—critical for batch production. Look for tool spindles with high rotational stability (≤0.001 mm runout) pour des tolérances serrées.

- CNC Milling Machines: Ideal for 3D parts. 3-axis mills handle basic shapes; 5-broyeurs à axes (par ex., DMG MORI CMX 50 U) cut complex angles (great for aerospace parts). Prioritize machine tool accuracy—look for 定位精度 (précision de position) of ±0.003 mm or better.

- Grinding Machines: Includes surface grinders (pour pièces plates) and cylindrical grinders (for shafts). Choose machines with automatic wheel dressing (keeps the abrasive wheel sharp) to maintain consistency.

- EDM Machines: Sink EDM (for cavities) and wire EDM (for cutting) are the two main types. Wire EDM machines (par ex., Sodick AQ325L) use brass or copper wire—thinner wire means finer details.

- Laser Cutting Machines: CO₂ lasers work for non-metals (plastiques, bois); fiber lasers are better for metals (acier, aluminium). Look for laser power (100-500 W) matching your material thickness (par ex., 500 W cuts 10 mm steel).

- High-Precision Machine Centers: All-in-one tools that combine milling, tournant, et forage. Perfect for complex parts (par ex., implants médicaux) where multiple operations need to be done in one setup (reduces error from repositioning).

Common Mistake: Using a general-purpose CNC mill for ultra-precision work (par ex., ±0,001 mm). Invest in a high-precision machine center if your parts demand extreme accuracy—this saves time on rework.

3. Mesure et inspection: Ensuring Accuracy Every Step

Precision machining means “measure twice, cut once.” You need to inspect parts at every stage (pré-usinage, en cours, post-usinage) to catch errors early. Here’s your inspection toolkit:

Key Tools & Leurs utilisations

| Tool | But | Précision | Idéal pour |

| Machines à mesurer tridimensionnelles (MMT) | 3D measurement of complex parts. | ±0.001-±0.005 mm | Final inspection of critical parts (par ex., composants aérospatiaux). |

| Optical Measuring Instruments | Uses cameras/lenses to measure without contact. | ±0.0005-±0.01 mm | Petites pièces (par ex., connecteurs électroniques) or delicate materials (plastiques). |

| Jauges | Fixed tools for checking specific dimensions (par ex., taille du trou). | ±0,001 mm | Quick in-process checks (par ex., using a plug gauge to verify hole diameter). |

| Micromètres | Measure small lengths (par ex., part thickness). | ±0,001 mm | Checking cylindrical parts (par ex., shaft diameter) or thin walls. |

| Étriers | Vernier (manuel) or digital—measure lengths, widths, depths. | ±0,02 mm (vernier); ±0,001 mm (digital) | Fast checks of basic dimensions (par ex., part length). |

| Surface Roughness Meters | Measures surface texture (Valeur Ra). | ±0.001 μm | Ensuring finish quality (par ex., Râ 0.8 μm for a bearing surface). |

Inspection Best Practices

- Follow inspection standards (par ex., OIN 9001 for quality management, AS9100 pour l'aérospatiale). These ensure consistency across batches.

- Do in-process checks every 10-15 parties (for batch production) to catch tool wear early. Par exemple, if a milling tool wears down, it may produce parts 0.005 mm smaller than intended—catching this early saves 50+ pièces défectueuses.

- Utiliser measurement accuracy that’s 10x better than your part’s tolerance. If your part needs ±0.01 mm tolerance, use a tool accurate to ±0.001 mm (par ex., a digital micrometer).

4. Materials and Workpieces: Matching Material to Process

The material you choose affects every step—from tool selection to machining speed. Not all materials are “machinable,” so picking the right one saves frustration.

Matériaux courants & Machining Tips

| Type de matériau | Exemples | Usinabilité | Key Tips |

| Métaux | Aluminium, acier, laiton, cuivre | Aluminium (excellent); acier (good); cuivre (fair) | Utiliser de l'acier rapide (HSS) tools for aluminum; carbide tools for steel. |

| Alliages | Alliage de titane (Ti-6Al-4V), acier inoxydable (304) | Titane (pauvre); acier inoxydable (fair) | Slow spindle speeds (500-1000 tr/min) for titanium—prevents tool overheating. |

| Plastiques | ABS, COUP D'OEIL, nylon | ABS (excellent); COUP D'OEIL (fair) | Use sharp tools to avoid melting; cool the workpiece with compressed air. |

| Composites | Polymère renforcé de fibres de carbone (CFRP) | Équitable | Use diamond-coated tools—fibers wear down standard tools fast. |

| Céramique | Alumine, zircone | Pauvre (hard and brittle) | Use EDM or laser machining—traditional cutting breaks ceramics. |

| Hardened Materials | Acier trempé (CRH 50+), tungstène | Pauvre | Use grinding or wire EDM—turning/milling will damage tools. |

Préparation de la pièce

- Clean the workpiece: Remove oil, rouiller, or debris before machining—dirt can cause tool slippage and inaccurate cuts.

- Secure it properly: Use clamps or vises that distribute pressure evenly (par ex., for thin plastic parts, use soft jaws to avoid cracking).

- Check material properties: Know the material’s hardness (par ex., CRH 30 pour acier doux) and thermal expansion (par ex., aluminum expands 2x more than steel when heated)—this helps set cutting parameters.

Question: Why do my titanium parts keep breaking tools?

Answer: Titanium has low thermal conductivity—heat builds up in the tool (not the chip). Utiliser des outils en carbure (résistant à la chaleur), slow spindle speeds (≤1000 rpm), and high coolant flow to keep the tool cool.

5. Optimisation des processus: Boost Efficiency Without Losing Precision

Optimization is about making parts faster, moins cher, and better—without sacrificing accuracy. Here’s how to do it:

Key Optimization Factors

- Paramètres de coupe: The “big three” are spindle speed, vitesse d'avance, et profondeur de coupe. Par exemple, when milling aluminum:

- Vitesse de broche: 2000-3000 tr/min (rapide, since aluminum is soft)

- Vitesse d'alimentation: 100-200 mm/min (balances speed and finish)

- Depth of cut: 1-3 mm (avoids tool chatter)

- Sélection d'outils: Match the tool to the material and operation. For drilling steel, use a twist drill with a 135° point angle (cuts cleanly). For finishing, use a ball-end mill (gives smooth surfaces).

- Durée de vie de l'outil: Extend tool life by:

- Using coolant (reduces heat and wear)

- Dressing grinding wheels regularly

- Avoiding overloading the tool (par ex., depth of cut ≤ tool diameter for milling)

- Process Simulation: Use software like Mastercam or Siemens NX to simulate the machining process. This catches collisions (par ex., tool hitting the clamp) and optimizes tool paths—saving 10-20% of production time.

- Optimization Algorithms: AI-powered tools (par ex., Siemens Optisphere) analyze past machining data to suggest the best parameters. Par exemple, they might recommend increasing feed rate by 15% for a specific aluminum part—boosting speed without losing precision.

Cost-Effective Machining Tips

- Batch similar parts together (par ex., all aluminum shafts in one run) to reduce tool changes and setup time.

- Reuse tools for roughing (par ex., a worn carbide tool can still handle rough cuts) before using new tools for finishing.

- Use high-speed machining (HSM) for soft materials like aluminum—cuts faster with smaller chips, reducing cycle time by 30%.

6. Applications and Industries: Where Precision Machining Shines

Precision machining is everywhere—any industry that needs tight-tolerance parts relies on it. Here’s how key sectors use it:

Industry-Specific Uses

- Industrie automobile: Makes engine parts (par ex., crankshafts with ±0.005 mm tolerance) and transmission components. CNC turning is common for high-volume parts.

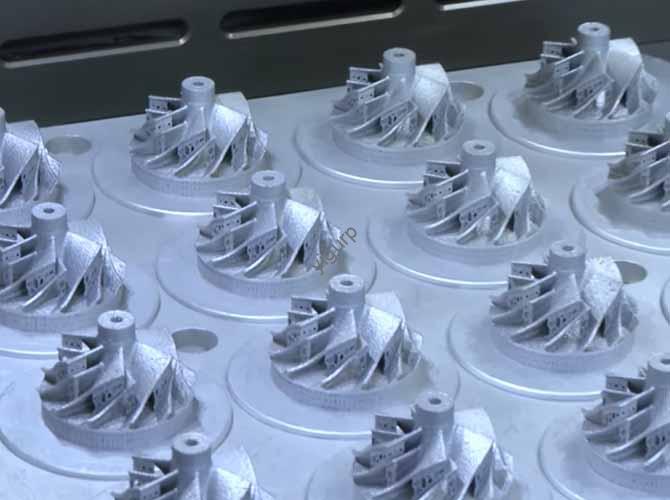

- Industrie aérospatiale: Produces turbine blades (EDM for complex shapes) and aircraft structural parts (5-axis milling for angles). Tolerances as tight as ±0.001 mm are standard.

- Dispositifs médicaux: Creates implants (par ex., titanium hip joints, lapped for smoothness) et outils chirurgicaux (laser machining for small features). Matériaux biocompatibles (par ex., 316L acier inoxydable) sont critiques.

- Industrie électronique: Makes circuit board components (drilling for tiny holes) and smartphone frames (CNC milling for thin walls). Precision ensures parts fit in small devices.

- Génie mécanique: Builds gears (honing for accuracy) and bearings (grinding for smooth surfaces). Reliable performance depends on tight tolerances.

- Fabrication d'outils et de matrices: Uses wire EDM to cut complex die shapes (par ex., for plastic injection molds). Precision ensures molds produce consistent parts.

- Biens de consommation: Creates high-end items like watch cases (CNC milling for intricate designs) and kitchen knives (grinding for sharp edges).

- Équipement industriel: Makes pump components (lapping for leak-proof seals) and conveyor rollers (turning for straightness). Durability relies on precise machining.

- Instruments de précision: Produces 显微镜 (microscope) lentilles (lapping for clarity) and measuring tools (par ex., micromètres, machined to ±0.0005 mm).

Yigu Technology’s View

Chez Yigu Technologie, we believe precision machining is a balance of technique, outils, and data. We pair high-precision CNC centers (±0.002 mm accuracy) with AI-driven process simulation to cut rework by 25%. For tough materials like titanium, we use diamond-coated tools and optimized coolant systems. We also prioritize in-process inspection with CMMs to catch errors early. Our goal is to deliver parts that meet the strictest tolerances—whether for aerospace or medical use—while keeping production efficient and cost-effective.

FAQs

- Q: What’s the difference between CNC turning and CNC milling?

UN: CNC turning rotates the workpiece (best for cylindrical parts like shafts), while CNC milling rotates the cutting tool (best for complex 3D parts like brackets). Choose turning for round parts, milling for shapes with flat or angled surfaces.

- Q: How do I choose between EDM and laser machining for hard materials?

UN: Use EDM for thick, complex 3D parts (par ex., mold cavities) or when you need no thermal damage. Use laser machining for thin materials (par ex., 1 mm steel) or small, simple cuts (par ex., holes in circuit boards)—it’s faster for these tasks.

- Q: How can I reduce tool wear in precision machining?

UN: Use the right tool material (carbide for steel, diamant pour composites), keep the workpiece cool with coolant, set optimal cutting parameters (avoid overloading), and dress grinding wheels or replace cutting tools regularly.