Dans la fabrication moderne, le Processus d'impression 3D en métal has emerged as a transformative technology, redéfinir la façon dont les pièces métalliques complexes sont conçues et produites. Contrairement aux méthodes traditionnelles (comme le moulage ou l'usinage) qui limitent souvent la flexibilité de conception et les déchets, metal 3D printing builds parts layer by layer—unlocking unprecedented freedom for creating intricate shapes while boosting efficiency. Whether you’re an engineer designing aerospace components, a procurement specialist sourcing production solutions, or a business owner exploring low-volume manufacturing options, comprendre le Processus d'impression 3D en métal is key to making informed, cost-effective decisions. This guide breaks down the most common metal 3D printing processes, leurs atouts, applications du monde réel, critères de sélection, et les tendances futures.

Key Metal 3D Printing Processes: How They Work and Their Advantages

Chaque Processus d'impression 3D en métal uses unique technology to melt, fusible, or bond metal materials—making them suitable for different industrial needs. Below’s a detailed look at the most widely used processes, with practical examples to illustrate their value:

1. Nanoparticle Jet Metal Molding (NPJ)

- Comment ça marche: NPJ uses inkjet technology to deposit nano-liquid metal droplets onto a build platform, where the droplets solidify layer by layer.

- Avantages principaux: Exceptionally fast printing speed (up to 5x faster than some laser-based processes), haute précision (down to 0.01mm), and smooth surface roughness (Râ < 1µm)—eliminating the need for extensive post-processing.

- Applications idéales: Haute précision, high-volume parts like medical device components (par ex., tiny surgical tools) or electronics connectors.

- Exemple concret: A medical device manufacturer in Germany uses NPJ to print micro-needles for insulin pens. The process produces 1,000 needles per hour with consistent sharpness—something traditional machining couldn’t achieve without costly tooling. The company reduced production time by 60% and defect rates from 8% à 1%.

2. Fusion laser sélective (GDT)

- Comment ça marche: SLM utilise un laser haute puissance (usually fiber laser) to fully melt metal powder particles (par ex., titane, acier inoxydable) into a solid layer. The build platform lowers after each layer, and new powder is spread—repeating until the part is complete.

- Avantages principaux: Produces parts with 99.5%+ densité (comparable to forged metal), excellent mechanical strength, et haute précision. It’s one of the most versatile processes for complex, pièces porteuses.

- Applications idéales: Aérospatial (par ex., pales de turbine), automobile (par ex., lightweight engine parts), and dental (par ex., custom crowns).

- Exemple concret: An aerospace firm in the U.S. uses SLM to print titanium turbine blades for jet engines. The blades have intricate internal cooling channels (too small for machining) that improve fuel efficiency by 12%. SLM also reduced material waste from 70% (with machining) à 15%.

3. Frittage sélectif au laser (SLS)

- Comment ça marche: SLS is similar to SLM but uses lower laser power—sintering (fusing) metal powder particles instead of fully melting them. It often requires post-processing (par ex., infiltration with resin or heat treatment) to boost density.

- Avantages principaux: Lower equipment costs than SLM, ability to print with mixed materials (par ex., métal + céramique), and no need for support structures (unsintered powder acts as support).

- Applications idéales: Low-stress parts like prototypes, éléments décoratifs, or ceramic-metal hybrid parts (par ex., heat-resistant sensors).

- Exemple concret: A consumer electronics brand uses SLS to print prototype phone chassis. The process lets them test 5 different designs in a week (contre. 4 weeks with machining) et les coûts 40% less than SLM for small batches. Post-processing with heat treatment ensures the prototypes are strong enough for drop tests.

4. Laser Near-Net Forming (LENS)

- Comment ça marche: LENS uses a nozzle to feed metal powder directly onto the build surface, where a laser melts the powder at the point of deposition. This “on-the-fly” melting lets it build parts or repair existing ones.

- Avantages principaux: Enables mold-free manufacturing (saving tooling costs), can repair damaged metal parts (par ex., worn gears), and works with large build volumes (up to 1m x 1m).

- Applications idéales: Industrie lourde (par ex., repairing mining equipment parts), pétrole et gaz (par ex., pressure vessel components), and large-scale aerospace parts.

- Exemple concret: A mining company in Australia uses LENS to repair worn drill bits. Instead of replacing bits every 3 mois (coût \(5,000 chaque), LENS repairs them in 8 heures pour \)800—extending their lifespan to 9 mois. This saved the company $240,000 annuellement.

5. Fusion par faisceau d'électrons (EBM)

- Comment ça marche: EBM uses a high-energy electron beam (instead of a laser) to melt metal powder in a vacuum. The build platform is preheated to high temperatures (jusqu'à 1 000°C), reducing residual stress in the final part.

- Avantages principaux: Faster scanning speed than SLM (up to 3x faster for large parts), lower residual stress (minimizing warping), and ability to print with reactive metals (par ex., titane, tantale) without oxidation.

- Applications idéales: Implants médicaux (par ex., tiges de hanche), aérospatial (par ex., large structural parts), and high-temperature components.

- Exemple concret: A medical implant manufacturer uses EBM to print titanium hip stems. The preheated platform eliminates stress, so the stems don’t crack under the body’s weight. EBM also prints stems 25% plus rapide que SLM, letting the company meet demand for 1,000+ implants per month.

6. FDM-Based Metal Extrusion

- Comment ça marche: This process uses plastic filaments infused with metal particles (par ex., 80% métal, 20% plastic binder). Après l'impression, the part goes through two post-processing steps: dégraissage (removing the plastic binder) and sintering (melting the metal particles into a solid).

- Avantages principaux: Low equipment costs (entry-level printers under $10,000), easy operation (similar to plastic FDM), and safe for small workshops (no high-power lasers).

- Applications idéales: Petites entreprises, amateurs, or low-volume parts like custom fasteners, bijoux, or educational models.

- Exemple concret: A small hardware startup uses FDM-based metal extrusion to print custom bolts for vintage cars. The process costs 70% less than SLM, and sintering ensures the bolts are strong enough to meet automotive standards. The startup now sells 500+ bolts monthly to classic car enthusiasts.

7. Frittage laser direct des métaux (DMLS)

- Comment ça marche: DMLS uses a laser to sinter metal alloys (par ex., acier inoxydable, aluminium, nickel-based superalloys) into dense parts. It’s often confused with SLM but uses slightly lower laser power—though parts still reach 98%+ densité.

- Avantages principaux: Works with nearly any metal alloy, produces parts with no internal defects (critical for high-stress applications), and supports complex geometries (par ex., structures en treillis).

- Applications idéales: High-stress parts like automotive suspension components, fixations aérospatiales, and industrial valves.

- Exemple concret: A Formula 1 team uses DMLS to print aluminum suspension brackets. The brackets are 30% lighter than machined ones (improving race speed) and can withstand 5x the load of plastic alternatives. DMLS also lets the team iterate on designs in 2 jours (contre. 2 semaines avec des méthodes traditionnelles).

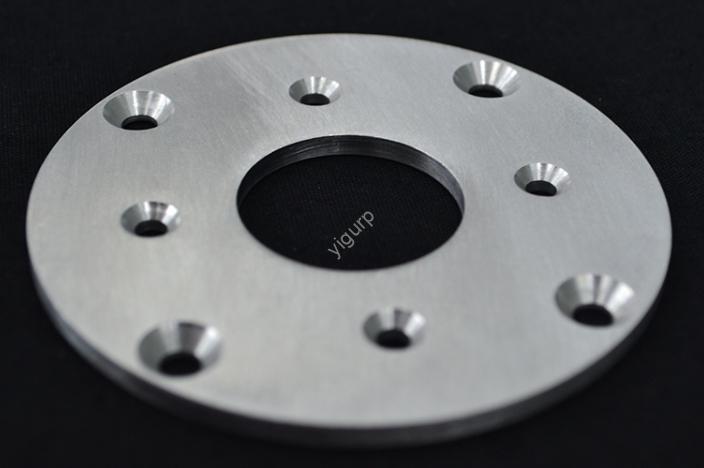

8. Metal Binder Jetting

- Comment ça marche: Metal Binder Jetting uses inkjet nozzles to deposit a liquid adhesive onto a metal powder bed, bonding the powder into layers. Après l'impression, the part is “debinded” (removing the adhesive) and sintered to fuse the metal.

- Avantages principaux: Vitesse d'impression rapide (up to 10x faster than SLM for large batches), pas besoin de structures de support, and ability to print large parts (par ex., 1je suis grand).

- Applications idéales: Low-to-medium stress parts like automotive heat shields, biens de consommation (par ex., metal vases), and architectural models.

- Exemple concret: A car manufacturer uses Metal Binder Jetting to print stainless steel heat shields for electric vehicles. The process produces 500 shields per day (contre. 100 with SLM) et les coûts 35% moins. Sintering ensures the shields can handle temperatures up to 600°C.

9. Direct Energy Deposition (DED)

- Comment ça marche: DED feeds metal powder or wire into a high-energy source (par ex., laser, faisceau d'électrons, or plasma arc), which melts the material as it’s deposited. It’s often used to add material to existing parts (par ex., strengthening a gear) or build large components.

- Avantages principaux: Can repair or modify parts (extending their lifespan), works with large build volumes, and supports multi-material printing (par ex., adding a corrosion-resistant layer to a steel part).

- Applications idéales: Aérospatial (par ex., repairing turbine casings), pétrole et gaz (par ex., strengthening pipeline components), et marin (par ex., ship propeller repairs).

- Exemple concret: An airline uses DED to repair titanium turbine casings on jet engines. Instead of replacing a casing for \(100,000, DED adds material to worn areas for \)10,000—extending the casing’s life by 5 années.

Metal 3D Printing Process Comparison: A Data-Driven Table

To help you quickly compare options, here’s a breakdown of key metrics for each Processus d'impression 3D en métal—based on industry data and real-user feedback:

| Processus | Densité des pièces | Printing Speed | Précision (mm) | Equipment Cost | Ideal Part Size | Best For Industries |

| NPJ | 98–99% | Très rapide | 0.01–0,05 | \(200k–\)500k | Small-Medium | Médical, Électronique |

| GDT | 99.5%+ | Moyen | 0.02–0,1 | \(150k–\)800k | Small-Medium | Aérospatial, Automobile, Dentaire |

| SLS (Métal) | 90–95% | Medium-Fast | 0.1–0,2 | \(100k–\)400k | Small-Medium | Prototypage, Biens de consommation |

| LENS | 98–99% | Moyen | 0.1–0,3 | \(120k–\)600k | Grand | Heavy Industry, Exploitation minière |

| EBM | 99%+ | Medium-Fast | 0.05–0,2 | \(250k–\)1M | Medium-Large | Médical, Aérospatial |

| FDM Metal Extrusion | 95–97% | Slow-Medium | 0.1–0,3 | \(5k–\)50k | Small-Medium | Petites entreprises, Amateurs |

| DMLS | 98–99% | Moyen | 0.03–0,1 | \(180k–\)700k | Small-Medium | Aérospatial, High-Stress Parts |

| Metal Binder Jetting | 96–98% | Très rapide | 0.05–0,2 | \(150k–\)600k | Small-Large | Automobile, Biens de consommation |

| DED | 97–99% | Slow-Medium | 0.1–0.4 | \(100k–\)800k | Grand | Aérospatial, Huile & Gaz |

How to Choose the Right Metal 3D Printing Process

Selecting the best Processus d'impression 3D en métal depends on four critical factors—aligning the process with your part’s requirements and business goals:

1. Part Requirements: Précision, Force, and Geometry

- Haute précision (par ex., medical micro-parts): Choose NPJ or SLM (both offer sub-0.1mm precision).

- Haute résistance (par ex., pièces de turbine aérospatiale): GDT, DMLS, or EBM (all produce 99%+ density parts).

- Géométrie complexe (par ex., structures en treillis): GDT, DMLS, or Metal Binder Jetting (no support structures needed).

- Exemple: A dental lab needs custom crowns with 0.05mm precision and biocompatibility. SLM is the best choice—it prints titanium crowns with the required accuracy and density.

2. Volume de production: Prototypage vs. Production de masse

- Prototypage (1–10 pièces): SLS or FDM Metal Extrusion (faible coût, délai d'exécution rapide).

- Production en faible volume (10–100 pièces): SLM or DMLS (balance of speed and quality).

- Production en grand volume (100+ parties): Metal Binder Jetting or NPJ (fastest speeds, lowest per-part cost).

- Exemple: A startup testing 3 prototype engine parts chooses SLS—it costs \(500 par pièce (contre. \)1,200 with SLM) and delivers parts in 3 jours.

3. Compatibilité des matériaux: Metal Type and Properties

- Reactive Metals (par ex., titane, tantale): EBM (vacuum environment prevents oxidation).

- Mixed Materials (par ex., métal + céramique): SLS (supports multi-material printing).

- Common Alloys (par ex., acier inoxydable, aluminium): GDT, DMLS, or Metal Binder Jetting (all work with these materials).

- Exemple: An aerospace company printing nickel-based superalloy turbine blades uses DMLS—it’s compatible with the alloy and produces parts that withstand high temperatures.

4. Cost Budget: Equipment and Operational Costs

- Low Budget (petites entreprises): FDM Metal Extrusion (equipment under $50k) ou SLS (lower per-part cost for prototypes).

- Medium Budget (mid-sized manufacturers): SLM or Metal Binder Jetting (balance of cost and quality).

- High Budget (large enterprises): EBM or DED (for high-performance, grandes pièces).

- Exemple: A small jewelry brand uses FDM Metal Extrusion to print silver pendants. The printer costs \(10k, and sintering adds only \)2 per pendant—making it affordable for low-volume sales.

Future Trends in Metal 3D Printing Process

Le Processus d'impression 3D en métal évolue rapidement, with three key trends shaping its future:

- Faster Speeds: Nouvelles technologies (par ex., multi-laser SLM printers) are cutting print times by 50%. Par exemple, a multi-laser SLM printer can print a turbine blade in 4 heures (contre. 8 hours with a single laser).

- Cheaper Materials: Recycled metal powders are becoming more common, reducing material costs by 30%. A European supplier now sells recycled titanium powder for \(150/kilos (contre. \)220/kg for virgin powder).

- Volumes de construction plus importants: DED and EBM machines with build volumes of 2m x 2m are being developed, enabling 3D printing of full-size aerospace components (par ex., wing sections) or industrial machinery parts.

Yigu Technology’s View on Metal 3D Printing Process

Chez Yigu Technologie, nous voyons le Processus d'impression 3D en métal as a cornerstone of smart manufacturing. We’ve helped clients across industries—from medical device makers to aerospace firms—choose the right process: advising a dental lab to use SLM for crowns, and a mining company to use LENS for part repairs. We also provide tailored solutions, like optimizing post-processing for SLS parts to boost density, or sourcing cost-effective recycled metal powders. As the technology advances, we believe metal 3D printing will become more accessible to small businesses, closing the gap between innovation and affordability. Our goal is to help every client unlock the full potential of metal 3D printing—reducing costs, improving part quality, et accélérer la mise sur le marché.

FAQ:

- Q: Is the Metal 3D Printing Process suitable for mass production (10,000+ parties)?

UN: Yes—for certain processes. Metal Binder Jetting and NPJ are fast enough for high-volume production. Par exemple, a car manufacturer uses Metal Binder Jetting to print 10,000 heat shields monthly, with per-part costs 20% lower than machining. SLM or DMLS are better for low-to-medium volumes, as their speed is slower for large batches.