Si tu as besoin de fort, tube sans soudure précis pour vérins hydrauliques, pièces automobiles, ou cadres structurels, tiré sur mandrin (DOMAINE) acier est l'étalon-or. Contrairement aux tubes soudés ou sans soudure standard, L'acier DOM a une épaisseur de paroi uniforme et une surface intérieure lisse, ce qui le rend idéal pour les applications à haute pression et de précision.. Ce guide détaille tout ce que vous devez savoir pour choisir, utiliser, and source DOM steel effectively.

1. Dessiné sur le mandrin (DOMAINE) Acier: Techniques de fabrication

DOM steel’s superior quality starts with a rigorous, multi-step manufacturing process. Here’s how it’s made, from raw material to finished tubing:

- Start with Seamless Steel Tubing: The process begins with seamless steel tubing (made via extrusion or piercing). This ensures no weld seams, which can weaken tubing under pressure.

- Recuit: The seamless tubing is heated to 800–900°C and cooled slowly (recuit). This softens the steel, making it easier to shape during drawing.

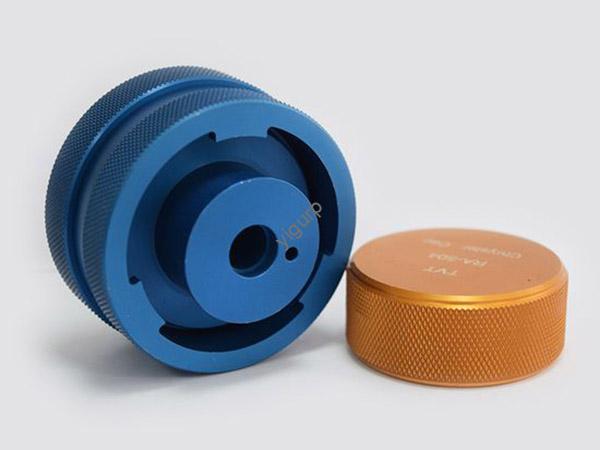

- Mandrel Insertion: A solid metal rod called a mandrel is inserted into the seamless tubing. The mandrel keeps the tube’s inner hole open and ensures uniform inner diameter (IDENTIFIANT) during drawing.

- Cold Drawing: The tubing (with mandrel inside) is pulled through a series of meurt (shaped openings) in a drawing machine. This reduces the outer diameter (DE) and wall thickness while stretching the tube to length. Cold working during this step strengthens the steel.

- Garniture & Coupe: After drawing, the tubing is cut to standard lengths (par ex., 6pi, 12pi) or custom sizes using precision saws.

- Final Heat Treatment: Optional but common—another round of annealing to reduce stress from cold drawing, or tempering to boost hardness for wear-prone parts.

- Inspection: The finished DOM tubing undergoes dimensional checks (DE, IDENTIFIANT, épaisseur de paroi) and surface inspections to ensure quality.

Real Example: A hydraulic cylinder manufacturer in Germany uses DOM steel tubing. Lefabrication de précision process ensures the tubing can handle 3,000 psi of hydraulic pressure without leaking—critical for heavy machinery.

2. Dessiné sur le mandrin (DOMAINE) Acier: Propriétés des matériaux

DOM steel’s unique manufacturing process gives it standout properties that make it better than welded or standard seamless tubing. Here’s how it performs:

| Propriété | Typical Values (Mild Steel DOM) | Advantage Over Welded Tubing |

|---|---|---|

| Résistance à la traction | 450–600 MPa | 20–30% higher (no weak weld seams) |

| Yield Strength | 300–400 MPa | Resists bending or deformation under load |

| Élongation | 15–25% | Ductile enough to form into shapes (par ex., virages) |

| Wall Thickness | Tolérance de ±0,05 mm | Uniform—avoids thin spots that can burst |

| Inner Surface Finish | Ra 0.8–1.6 μm | Smooth—reduces friction in hydraulic systems |

| Rondeur | ±0,1mm | Consistent shape—fits bearings and connectors |

| Fatigue Resistance | 10^6+ load cycles | Lasts longer in repetitive-use parts (par ex., arbres) |

Key Property: Précision dimensionnelle

DOM steel’sprécision dimensionnelle is its biggest strength. Par exemple, a 10mm OD DOM tube has an OD tolerance of just ±0.05mm—this means it will fit perfectly with connectors or bearings, no extra machining needed. Welded tubing, par contre, often has ±0.2mm tolerance, requiring additional work.

Material Composition

Most DOM steel is mild carbon steel (AISI 1018 is common) avec:

- Carbon (C): 0.15–0.20% (balances strength and ductility)

- Manganese (Mn): 0.60–0.90% (boosts tensile strength)

- Fer (Fe): 98–99% (base metal)

For corrosion-resistant needs, stainless steel DOM tubing (SUS304/SUS316) is available, with chromium (18–20%) et du nickel (8–10%) added to prevent rust.

3. Dessiné sur le mandrin (DOMAINE) Acier: Applications and Uses

DOM steel’s strength, précision, and seamless design make it essential in industries where reliability matters. Here are its top uses:

Machines industrielles

- Hydraulic cylinders: DOM tubing’s smooth inner surface reduces friction between the piston and tube, preventing leaks. A construction equipment maker uses DOM steel for excavator hydraulic cylinders—they last 50% longer than those made with welded tubing.

- Pneumatic cylinders: Similar to hydraulic cylinders, DOM steel handles compressed air pressure without bursting.

Industrie automobile

- Suspension components: DOM steel bars make up sway bars and control arms—their high tensile strength resists bending during sharp turns.

- Drive shafts: DOM tubing’s uniform wall thickness ensures balanced rotation, reducing vibration in cars and trucks.

Construction & Structural

- Furniture frames: DOM steel tubes are used for heavy-duty office chairs and gym equipment—they’re strong but lightweight. A fitness brand uses DOM steel for treadmill frames; the tubes support 300kg of weight without bending.

- Tubular structures: DOM steel forms railings and support posts in buildings—its straightness (±0.5mm per meter) ensures a clean, aspect professionnel.

Specialized Uses

- Marine applications: Stainless steel DOM tubing resists saltwater corrosion, making it ideal for boat rigging and hydraulic systems.

- Matériel médical: DOM steel is used for surgical tool handles—its smooth surface is easy to sterilize and doesn’t harbor bacteria.

4. Dessiné sur le mandrin (DOMAINE) Acier: Quality and Standards

To ensure you’re getting high-quality DOM steel, look for compliance with global standards and strict quality control measures.

Key Standards

| Standard Organization | Common Specs | Use Case |

|---|---|---|

| ASTM (NOUS.) | ASTM A513 (DOM steel tubing) | Hydraulic cylinders, pièces automobiles |

| AISI (NOUS.) | AISI 1018 (mild steel DOM), AISI 304 (stainless DOM) | Structural frames, outils médicaux |

| IL (Japan) | JIS G3445 (DOM seamless tubing) | Marine equipment, machines industrielles |

| DEPUIS (Europe) | DIN EN 10305-1 (precision DOM tubing) | Pneumatic cylinders, precision shafts |

| OIN (Mondial) | OIN 8539 (DOM steel for hydraulic use) | High-pressure hydraulic systems |

Mesures de contrôle de qualité

Reputable manufacturers use these steps to ensure DOM steel quality:

- Chemical Analysis: Tests check for carbon, manganèse, and other alloying elements to confirm they meet specs (par ex., 0.18% carbon for AISI 1018).

- Contrôle dimensionnel: Calipers and laser scanners verify OD, IDENTIFIANT, épaisseur de paroi, and straightness—ensuring they stay within tolerance.

- Non-Destructive Testing (CND): Ultrasonic testing checks for internal defects (par ex., fissures) that can’t be seen with the naked eye.

- Surface Inspection: Visual checks or profilometers ensure the outer and inner surfaces are smooth (no scratches or pits).

- Mechanical Testing: Tensile tests measure strength, while bend tests check ductility—samples are pulled or bent until they break to confirm performance.

Pro Tip: Always ask for a Certificate of Compliance (CoC) or Mill Test Report (MTR) when buying DOM steel. These documents prove the tubing meets your chosen standard.

Yigu Technology’s Perspective

Chez Yigu Technologie, nous recommandonstiré sur mandrin (DOMAINE) acier for clients needing high-pressure, precision tubing. We supply ASTM A513 DOM steel (mild steel and stainless steel) avec des tolérances serrées (±0.03mm for wall thickness) for hydraulic and automotive projects. Our quality checks include ultrasonic NDT and dimensional scans, so clients trust the tubing can handle tough conditions. We also offer custom cutting to reduce waste—for example, a hydraulic client saved 15% on material costs by ordering 8ft custom lengths instead of standard 12ft tubes.

FAQ

- Is DOM steel better than seamless steel for hydraulic cylinders?

Yes—standard seamless steel has less uniform wall thickness (Tolérance de ±0,1 mm) and a rougher inner surface. DOM steel’s ±0.05mm tolerance and smooth ID reduce friction and leaks, making it more reliable for hydraulic systems. - Can DOM steel be bent or welded?

Yes—DOM steel is ductile enough for bending (use a tube bender to avoid kinks). It also welds well with MIG or TIG welding, but preheat to 150–200°C first to reduce stress from cold working. - How do I choose between mild steel and stainless steel DOM tubing?

Choose mild steel DOM for indoor, dry applications (par ex., meubles, pièces automobiles)—it’s cheaper. Choose stainless steel DOM for outdoor, wet, or corrosive environments (par ex., marin, médical)—it resists rust but costs more.