Copper is a go-to material for pièces de précision—thanks to its unbeatable electrical conductivity et conductivité thermique—but machining it into high-quality sample models requires the right equipment. Tours de type suisse, with their unique douille de guidage and “done-in-one” capabilities, sont parfaits pour le travail. Ils transforment les barres de cuivre en modèles d'échantillons avec des tolérances serrées., surfaces lisses, and consistent performance—critical for testing parts before mass production. This article breaks down the core characteristics of these copper samples, from material perks to real-world uses, to help you get the most out of Swiss-type lathe machining.

1. Material Properties of Copper: Why It’s Ideal for Precision Samples

Copper’s natural properties make it a favorite for sample models, especially in industries like electronics and aerospace. These properties not only define the sample’s performance but also shape how you machine it with a Swiss-type lathe.

Core Properties of Copper & Their Impact

| Propriété | Description | Benefit for Sample Models | Machining Consideration |

| Conductivité électrique | 59.6 × 10⁶ S/m (second only to silver) | Perfect for testing electrical components (par ex., connector samples) — mimics final part’s current-carrying ability. | Avoid overheating during machining (heat reduces conductivity temporarily). Use coolant to keep temperatures low. |

| Conductivité thermique | 401 Avec(m·K) | Ideal for heat exchanger samples — lets you test heat transfer efficiency accurately. | Copper dissipates heat fast, so cutting tools stay cool (réduit l'usure des outils). |

| Ductilité | Can be stretched into thin wires without breaking (allongement à la rupture: 45-50%) | Easy to machine into complex shapes (par ex., thin-walled copper tubes for sensor samples). | Use sharp tools to prevent “tearing” the material (dull tools cause rough surfaces). |

| Résistance à la corrosion | Resists rust and most chemicals (except strong acids like nitric acid) | Samples last longer for repeated testing (no need to replace corroded prototypes). | No special coatings needed for short-term sample use — saves time and cost. |

Quick Example: A manufacturer making electrical connector samples uses copper because its conductivity matches the final part. The sample’s performance in conductivity tests directly predicts how the mass-produced connector will work—something you can’t get with cheaper materials like aluminum.

2. Swiss-Type Lathe Machining Process for Copper Samples

Swiss-type lathes simplify machining copper samples by combining multiple operations in one setup. This eliminates errors from moving the workpiece and ensures consistency across sample batches. Here’s how the process works for copper:

Step-by-Step Machining Workflow

- Bar Stock Preparation: Load copper bar stock (diamètre 5-20 mm, common for samples) into the lathe’s bar feeder. Cut the bar to a length 10-15% longer than the sample (leaves room for finishing).

- Chucking & Guide Bushing Setup: The lathe’s mandrin holds the bar, while the douille de guidage supports it near the cutting tool. For copper (doux et ductile), the bushing’s inner diameter should be 0.001-0.002 mm larger than the bar—prevents bending without damaging the material.

- Tournant: Shape the copper into the basic form (par ex., a cylindrical sensor housing). Use a carbide turning insert (grade K10-K20, ideal for non-ferrous metals). Set cutting speed to 1,500-2,500 rpm and feed rate to 0.02-0.03 mm/rev—fast enough for efficiency, slow enough to avoid tool chatter.

- Fraisage (si nécessaire): Add features like slots or flats (par ex., for mounting a copper switch sample). Use a live tool turret with a carbide end mill (diamètre 1-5 mm). For copper, mill in 0.5 mm depth increments to prevent tool overload.

- Finishing Cuts: Do a light final turn (profondeur de coupe 0.1-0.2 mm) to reach the sample’s exact dimensions. This smooths any tool marks from rough machining.

- Parting: Cut the finished copper sample from the bar using a parting tool (width 1.5x the sample’s diameter). For a 10 mm diameter sample, utiliser un 15 mm wide tool—avoids pinching the soft copper.

Pour un pourboire: For small copper samples (par ex., 2 mm diameter pins), skip the chuck and use the guide bushing alone for support. This reduces contact points and keeps the sample straight—critical for parts that need to fit into tight spaces.

3. Surface Finish and Quality of Copper Samples

A copper sample’s surface finish affects both its appearance and performance (par ex., a rough surface on a heat exchanger sample reduces heat transfer). Swiss-type lathes produce exceptional surface quality for copper—here’s what to expect:

Surface Finish Standards & Méthodes

| Surface Finish Type | Valeur Ra | Machining Method | Idéal pour |

| Functional Finish | 0.8-1.6 µm | Standard turning + light sanding | Samples tested for function (par ex., electrical conductivity—surface roughness doesn’t affect performance). |

| Precision Finish | 0.2-0.8 µm | Tournage à grande vitesse (2,500-3,000 tr/min) + polissage | Samples needing tight fits (par ex., copper valve cores that slide in a housing). |

| Mirror Finish | ≤0.02 μm | Tournant + affûtage + buffing | Appearance samples (par ex., copper decorative parts for consumer electronics). |

Common Surface Defects & Correctifs

- Torn Edges: Caused by dull tools. Réparer: Replace with a sharp carbide insert (grade K15) and reduce feed rate to 0.015 mm/tour.

- Chatter Marks: Caused by loose guide bushing. Réparer: Tighten the bushing (assurer 0.001 mm clearance) and lower spindle speed by 500 tr/min.

- Oxidation Spots: Caused by high machining temperatures. Réparer: Use a coolant mist system (mix 5% soluble oil with water) to keep the copper cool.

Étude de cas: A company making copper heat exchanger samples noticed poor heat transfer in tests. They checked the surface finish (Râ 2.0 µm) and re-machined the samples at 3,000 rpm with a sharp tool (Râ 0.6 µm). The new samples’ heat transfer efficiency improved by 15%—proving how surface quality impacts performance.

4. Dimensional Accuracy and Precision of Copper Samples

Copper’s ductility can make it tricky to hold tight tolerances, but Swiss-type lathes solve this with precise controls. The samples’ précision dimensionnelle directly determines how well they mimic the final part—critical for validating designs.

Accuracy Metrics for Copper Samples

| Métrique | Typical Range for Swiss-Turned Copper Samples | Pourquoi c'est important |

| Précision dimensionnelle | ±0.001-±0.005 mm | Ensures the sample fits with other parts (par ex., a copper connector sample that must plug into a plastic housing). |

| Tolérance | ±0,002 mm (for critical features like holes) | Répond aux normes de l'industrie (par ex., OIN 286-1 pour pièces mécaniques). |

| Répétabilité | ±0.001 mm across 50+ échantillons | Consistent test results (no variation between samples in a batch). |

Mesures & Inspection Tips

- Utilisez un digital micrometer (accuracy ±0.0001 mm) to check outer diameters (par ex., a copper tube sample’s wall thickness).

- For complex samples (par ex., copper parts with multiple holes), utiliser un Machine de mesure de coordonnées (MMT) to verify all dimensions in one pass.

- Do in-process inspection: Check the sample after finishing cuts—if it’s 0.003 mm oversize, adjust the turning tool’s offset by -0.003 mm for the next sample.

Question: Why is my copper sample’s diameter 0.004 mm smaller than the design?

Répondre: Copper shrinks slightly when cooling after machining (thermal contraction: ~16.5 × 10⁻⁶/°C). Pour résoudre ce problème, machine the sample 0.002-0.003 mm oversize. Par exemple, if the design calls for 10.000 mm, machine to 10.003 mm—it will shrink to 10.000 mm as it cools.

5. Tool Wear and Machining Parameters for Copper Samples

Copper is soft, so it’s easy on cutting tools—but poor parameter settings can still cause premature wear. Optimisation paramètres d'usinage and choosing the right tools keeps costs low and sample quality high.

Sélection d'outils & Wear Prevention

| Type d'outil | Ideal for Copper | Durée de vie de l'outil (per Sample Batch) | Wear Prevention Tips |

| Turning Inserts | Carbure (grade K10-K20); avoid HSS (wears fast) | 50-100 échantillons (pour 10 mm diameter parts) | Clean chips from the insert every 10 échantillons (copper chips stick and cause abrasion). |

| Fraises | Fraises en carbure monobloc (2-flûte, for non-ferrous metals) | 30-50 échantillons (for slots ≤2 mm deep) | Use a coating like TiN (nitrure de titane) pour réduire les frottements. |

| Forets | Carbide twist drills (135° angle de pointe) | 40-60 échantillons (for holes ≤3 mm diameter) | Add coolant to the drill tip—prevents built-up edge (ARC) on the tool. |

Optimal Machining Parameters

| Opération | Vitesse de coupe (tr/min) | Vitesse d'alimentation (mm/tour) | Profondeur de coupe (mm) |

| Rough Turning | 1,500-2,000 | 0.025-0.03 | 0.5-1.0 |

| Finish Turning | 2,500-3,000 | 0.01-0.015 | 0.1-0.2 |

| Fraisage (Machines à sous) | 2,000-2,500 | 0.01-0.02 | 0.3-0.5 |

| Forage (Trous) | 1,000-1,500 | 0.01-0.015 | Full hole depth (par ex., 5 mm for a 5 mm hole) |

Pour un pourboire: If you notice tool wear (par ex., a turning insert with a rounded edge), reduce the cutting speed by 200 tr/min. Cela prolonge la durée de vie de l'outil de 30% without slowing production too much.

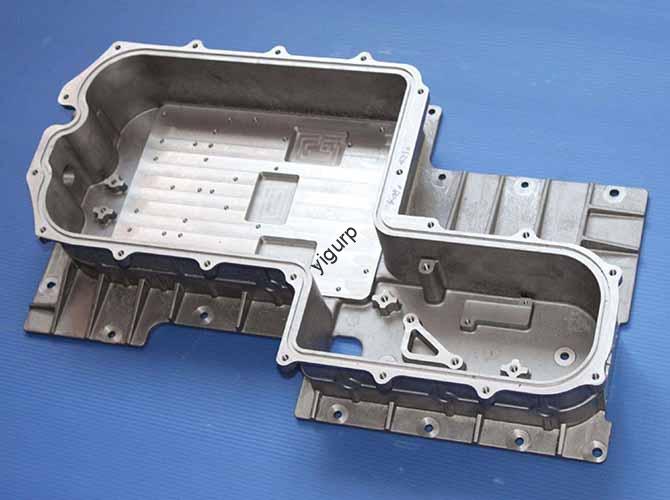

6. Applications and Advantages of Machined Copper Models

Swiss-turned copper samples are used across industries to test designs, valider les performances, and reduce risks before mass production. Their advantages make them a smart choice over samples made with other materials or machines.

Applications clés

- Composants électriques: Samples like copper connectors, bornes, and switch contacts—tested for conductivity and fit.

- Échangeurs de chaleur: Thin-walled copper tube samples—validate heat transfer efficiency and pressure resistance.

- Pièces industrielles: Copper valve cores, composants de la pompe, and sensor housings—test durability and functionality.

- Prototypage: Early-stage copper samples for new products (par ex., a smartwatch’s copper antenna)—quickly iterate on designs without expensive tooling.

Advantages of Swiss-Turned Copper Samples

- Performance Match: Copper’s properties mirror the final part (unlike plastic or aluminum samples), so test results are reliable. Par exemple, a copper heat exchanger sample’s performance directly predicts the mass-produced unit’s efficiency.

- Tolérances strictes: Swiss-type lathes produce samples with ±0.001 mm accuracy—critical for parts that need to fit (par ex., a copper pin that must slide into a 0.5 mm hole).

- Délai d'exécution rapide: “Done-in-one” machining cuts sample production time by 40% compared to conventional lathes (no need to move parts between machines).

- Rentable: Copper is affordable for small sample batches (10-50 parties), and Swiss-type lathes reduce waste (seulement 5-10% material loss).

Fun Fact: A startup making copper-based sensors used Swiss-turned samples to test 5 itérations de conception dans 2 semaines. Without these samples, they would have wasted 3 months and $10,000 on faulty mass-produced parts.

Yigu Technology’s View

Chez Yigu Technologie, we see Swiss-turned copper samples as a bridge between design and production. We use high-precision Swiss-type lathes (with guide bushing tolerance ±0.0005 mm) to machine copper samples, pairing them with carbide tools (grade K15) pour surfaces lisses. For clients in electronics/aerospace, we optimize parameters to hit ±0.001 mm accuracy, ensuring samples mimic final parts. We also offer in-process CMM checks to validate every sample. Our goal: help clients test confidently, iterate fast, and launch high-quality copper parts.

FAQ

- Q: Why use copper instead of brass for Swiss-turned samples?

UN: Copper has better electrical/thermal conductivity (brass is 60% less conductive) et une ductilité plus élevée (easier to machine into complex shapes). Brass is cheaper but doesn’t match the performance of pure copper for critical parts like connectors or heat exchangers.

- Q: How long does it take to make a batch of 20 copper samples with a Swiss-type lathe?

UN: For simple samples (par ex., 10 mm diameter pins), ça prend 1-2 heures (installation + usinage). For complex samples (par ex., copper tubes with slots), ça prend 3-4 hours—much faster than conventional lathes (5-6 heures).

- Q: Can Swiss-type lathes machine copper samples with wall thicknesses <0.5 mm?

UN: Oui! Use a guide bushing for support, a sharp carbide tool, and low feed rate (0.01 mm/tour). We’ve made copper samples with 0.2 mm wall thicknesses for medical sensors—they hold tight tolerances (±0,002 mm) and don’t deform.