Les prototypes d'usinage CNC sont essentiels au développement de produits, mais ils sont souvent confrontés à des problèmes évitables qui nuisent à la précision et à la qualité. En tant que stratège de contenu SEO et ingénieur produit, Je vais détailler les problèmes les plus fréquents, partager des correctifs du monde réel, et expliquer comment des choix intelligents (comme la sélection des matériaux) élever le succès des prototypes. Plongeons-nous.

1. Surcoupe de la pièce: Causes, Correctifs, and a Real Case

Overcutting—when the tool removes more material than planned—ruins prototype precision. Par exemple, a medical device manufacturer once made 50 acrylic prototypes for a surgical tool, mais 30 were overcut. The issue? A short tool that bent under pressure, plus incorrect feed rates.

Key Causes of Overcutting

| Cause | Description | Impact |

|---|---|---|

| Insufficient tool length | Short tools flex during cutting, leading to uneven material removal | Up to 0.3mm size deviation |

| Uneven cutting allowance | Thick/thin material spots force the tool to overcompensate | Rough edges and wrong dimensions |

| Poor cutting parameters | Too high feed rate or spindle speed | Overheating and tool wear (worsens overcutting) |

Practical Solutions

- Pick tools with enough length (par ex., use a 100mm length tool for 80mm deep cuts, not 85mm).

- Add a corner cleaning program to make allowance even (this fixed the medical device firm’s issue).

- Use the machine’s SF (Spindle Feed) fonction to tweak speed/feed rates mid-process—test with scrap material first!

2. Middle Division Problems: How to Avoid Misalignment

Middle division issues happen when the prototype’s center (or split parts) don’t line up. A consumer electronics client once struggled with plastic phone case prototypes: the top and bottom halves wouldn’t fit. The root? A magnetic middle rod that pulled the mold off-center, plus burrs on the mold edges.

Top Reasons for Misalignment

- Inaccurate manual operation (par ex., operator didn’t lock the mold tightly).

- Burrs around the mold (tiny metal/plastic bits push parts out of place).

- Magnetic middle rods (attract metal shavings, shifting the mold).

- Non-vertical mold sides (mold tilts, so cuts are uneven).

Step-by-Step Fixes

- Check manual setups 2x (the electronics client now requires a second operator to verify).

- Remove burrs with a 400-grit sandpaper and clean the mold with alcohol.

- Demagnetize the middle rod avant dividing the prototype (use a demagnetizer tool).

- Calibrate the table to check mold verticality—aim for a deviation of ≤0.02mm.

3. Tool Setting Errors: Costly Mistakes and Easy Fixes

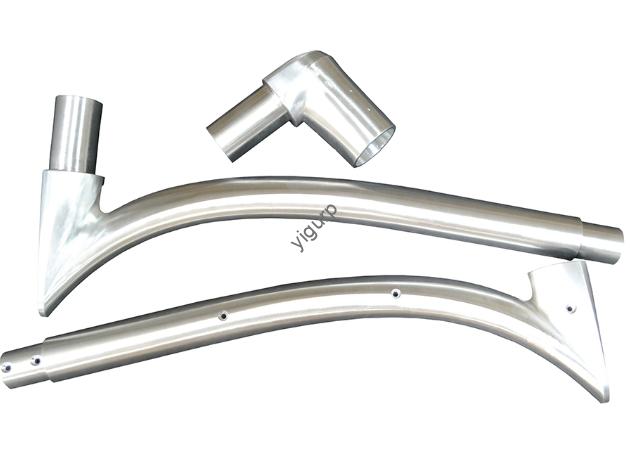

Tool setting problems (par ex., wrong tool type or loose clamping) cause up to 40% of prototype rejections, par données sectorielles. A furniture maker once used a flat-bottom knife instead of an R-knife for curved chair arm prototypes—all 20 parts had sharp edges that didn’t match the design.

Common Tool Setting Issues

- Operator mixes up tools (par ex., R-knife vs. flat-bottom knife).

- Loose tool clamping (tool wobbles during cutting).

- Wrong blade on a flying cutter (blunt or mismatched size).

How to Prevent Errors

- Create a separate tool setting program for each tool (the furniture maker now uses a program that alerts operators if the wrong tool is loaded).

- Clean tool holders with a dry cloth before clamping—dust or shavings cause looseness.

- Do a “dry run” (no material) to test tool alignment—this catches 90% of setting mistakes.

4. Collisions: Why They Happen and How to Stop Them

Collisions (tool hits the machine or mold) damage equipment and destroy prototypes. UN 2023 survey found that 65% of collisions come from programming errors, alors que 35% are operator mistakes.

Main Causes of Collisions

| Taper | Exemples |

|---|---|

| Programming Errors | – Safety height too low (tool hits the mold when moving) – Wrong tool length/depth in the program – Incorrect coordinate settings |

| Operator Mistakes | – Wrong Z-axis depth when setting the tool – Using the wrong program for the prototype – Fast feeding in the wrong direction |

Preventive Measures

- Set a safety height of at least 10mm (more for tall prototypes).

- Cross-check the program sheet with the actual tool (par ex., confirm tool length is 50mm, not 45mm).

- Train operators on “slow feed” for first cuts—this gives time to stop if something’s wrong.

5. Sélection des matériaux, Précision dimensionnelle, and Surface Treatment

Even with no issues above, poor material or finish ruins prototypes. Here’s how to get these right:

Material Choices for Different Prototypes

| Product Requirement | Recommended Material | Use Case |

|---|---|---|

| Haute ténacité | Pennsylvanie (Nylon) or PP | Prototypes de jouets (need to resist drops) |

| Transparence | PMMA (Acrylique), Transparent ABS | Light fixture covers |

| Résistance à la chaleur | PC (Polycarbonate) | Pièces intérieures d'automobile |

Dimensional Accuracy Tips

- Ensure prototype dimensions match the drawing—even a 0.1mm difference needs approval from management or programmers.

- Use a caliper (précision: ±0,01mm) to check key points (par ex., diamètre du trou, edge length) after machining.

Surface Treatment for Transparent Prototypes

For products like clear phone cases or display covers, polissage boosts transparency. Use these steps:

- Sand the surface with 800-grit sandpaper.

- Polish with a buffing wheel and acrylic polish.

- Clean with a lint-free cloth—this makes the prototype 90% as clear as the final product.

Yigu Technology’s Perspective

Chez Yigu Technologie, we believe CNC machining prototype success lies in “prevention over correction.” We integrate material testing (par ex., checking PA’s toughness before use), simulation processing (to catch collisions early), and operator training into every project. Par exemple, we helped a tech startup reduce overcutting by 70% by optimizing their tool length and cleaning programs. By focusing on details—from tool setting to surface treatment—we deliver prototypes that match design goals and speed up product launches.

FAQ

- Q: How can I quickly check if my tool is set correctly?

UN: Do a dry run (no material) and use the machine’s “tool offset” function to verify alignment. If the tool’s path matches the program, it’s set right. - Q: What’s the best material for a transparent prototype that needs to be durable?

UN: Transparent PC (Polycarbonate) is ideal—it’s clear like acrylic but 2x more impact-resistant, making it great for prototypes like safety goggles. - Q: How do I fix minor overcutting on a prototype?

UN: For small overcuts (≤0.2mm), use fine sandpaper (1000-grincer) to smooth the edge. For larger issues, adjust the cutting parameters and re-machine a new part.