Services d'usinage CNC pour le prototype personnalisé

Un fournisseur fournissant des prototypes de métal et de plastique personnalisés à la production de petits lots, avec un ISO 9001:2015 usine. Nos capacités de traitement couvrent 80 types de métaux et plus que 50 types de matériaux plastiques. Nous avons fini 50 3, 4 et les machines CNC à 5 axes et peuvent compléter des prototypes ou des pièces personnalisées dans le plus rapide 2 jours. Livraison à l'échelle nationale. Le délai de livraison est généralement à l'intérieur 1 à 3 jours.

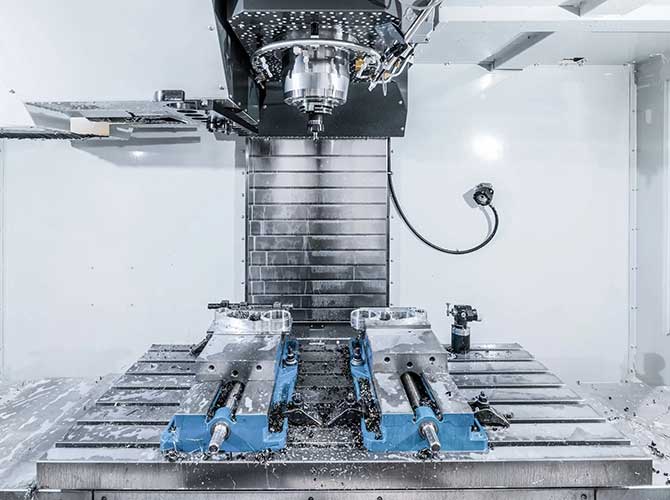

Services d'usinage CNC

Nos opérations d'usinage CNC ont une large gamme d'applicabilité et peuvent répondre à divers besoins d'usinage complexes. Nous avons divers centres de fraisage et de virage CNC, as well as EDM à fil CNC et CNC Grinceing, Forage CNC, Gravure CNC capacités, ce qui donne à Yigu une grande flexibilité pour produire différents types de prototypes et de pièces.

3-axis and 5-axe Moulin CNC

Yigu’s on-demand CNC milling service provides highly personalized customization. You can choose from a variety of materials, traitements de surface, and processing options to manufacture parts that meet your specific needs.

With a tolerance as low as 0.01 millimètres, your parts can be delivered nationwide within 2 days at the fastest.

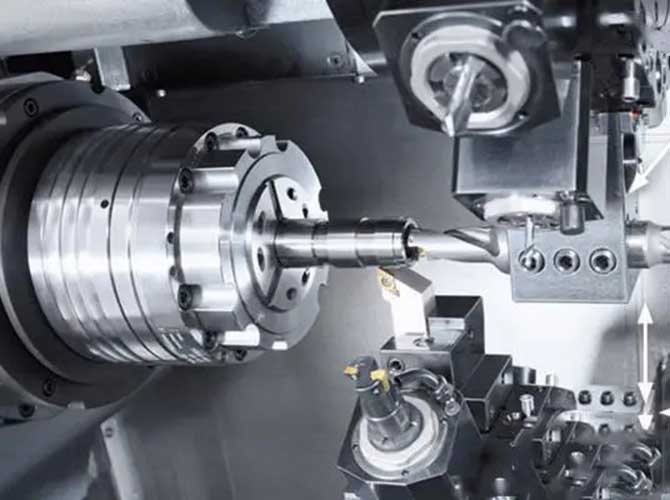

CNC tournant

Our CNC turning is used to manufacture cylindrical parts such as shafts, engrenages, boulons, et attaches, as well as parts with rotational symmetry.

With a tolerance as low as 0.01 millimètres, your parts can be delivered globally in as fast as 3 jours.

Prototype d'usinage CNC et affichage des pièces

Les produits affichés ci-dessous ont été approuvés par le client, Et nous respectons strictement l'accord de confidentialité pour protéger la confidentialité et la créativité du client.

Sélection des matériaux pour l'usinage CNC

Nous pouvons utiliser une variété de matériaux différents pour la production.

Plastique

Alliage en aluminium

Acier inoxydable

Acier doux

Acier en alliage

Outils

Autre métaux

Traitement de surface dans l'usinage CNC

Nous fournissons une variété de services de finition de surface pour répondre à vos divers besoins. Nous fournissons des services de traitement de surface tels que le polissage, lissage, tirage, impression d'écran en soie, sable, Anodisation, revêtement en poudre, électroplaste, passivation, et gravure laser.

Tolérance à l'usinage CNC

Yigu follows the DIN-2768-1-fine standard for metal processing and the DIN-2768-1-medium standard for plastic processing, providing a good balance between precision and cost-effectiveness, and is therefore widely used in the industry.

Our project manager will meticulously document every detail of the project and consult with you to ensure the highest possible precision is provided. When working with Yigu, we guarantee that all parts will be manufactured according to your specifications.

We follow the universal tolerance standards for CNC machining.

Pour les pièces métalliques, we follow DIN-2768-1-fine

Pour les pièces en plastique, we follow DIN-2768-1-Medium

Size Capabilities

| Taper | Précision |

|---|---|

| Trous filetés | – UNC & UNF threads: Depuis #2 jusqu'à 0.5 dans. – Metric threads: M1.2 and above |

| Radii | Turned outside corners will typically include a 0.005 dans. chamfer. |

| Taille du trou minimum | – Minimum on-axis and axial: 0.04 dans. (1MM) – Minimum radial: 0.08 dans. (0.5MM); 0.04 dans. (0.5MM) for aluminum brass |

| Rainures | – Minimum OD groove width: 0.047 dans. (1.2MM) – Minimum OD groove width for aluminum and brass: 0.019 dans. (0.5MM) – Maximum OD groove depth: 0.95 dans. (24.1MM) — varies with groove width |

| Linear Dimension | – ± 0.025mm – ± 0.001 pouces |

| Diamètre du trou (not reamed) | – ± 0.025mm – ± 0.001 pouces |

| Shaft Diameter | – ± 0.025mm – ± 0.001 pouces |

| Part Dimension Limit | – 950 * 550 * 480MM – 37.0 * 21.5 * 18.5 pouces |

CNC Machining Standards

Tolérances dimensionnelles (DIN ISO 2768-1 (1991-06))

| Tolerance Class | Type de matériau | Dimension Range (MM) | Tolérance (MM) |

|---|---|---|---|

| F | Métal (ISO 2768-F) | 0.5 à 3 | ± 0,05 |

| F | Métal (ISO 2768-F) | Sur 3 à 6 | ± 0,05 |

| F | Métal (ISO 2768-F) | Sur 6 à 30 | ± 0,1 |

| F | Métal (ISO 2768-F) | Sur 30 à 120 | ±0.15 |

| F | Métal (ISO 2768-F) | Sur 120 à 400 | ±0.2 |

| F | Métal (ISO 2768-F) | Sur 400 à 1000 | ±0.3 |

| F | Métal (ISO 2768-F) | Sur 1000 à 2000 | ±0.5 |

| F | Plastique (ISO 2768-F) | 0.5 à 3 | ± 0,05 |

| F | Plastique (ISO 2768-F) | Sur 3 à 6 | ± 0,05 |

| F | Plastique (ISO 2768-F) | Sur 6 à 30 | ± 0,1 |

| F | Plastique (ISO 2768-F) | Sur 30 à 120 | ±0.15 |

| F | Plastique (ISO 2768-F) | Sur 120 à 400 | ±0.2 |

| F | Plastique (ISO 2768-F) | Sur 400 à 1000 | ±0.3 |

| F | Plastique (ISO 2768-F) | Sur 1000 à 2000 | ±0.5 |

General Tolerances for Shape and Position (DIN ISO 2768-2 (1991-04))

| Tolerance Class | Caractéristiques | Dimension Range (MM) | Tolérance (MM) |

|---|---|---|---|

| H | Straightness and Flatness | 10 | ± 0,02 |

| H | Straightness and Flatness | 10 à 30 | ± 0,05 |

| H | Straightness and Flatness | 30 à 100 | ± 0,1 |

| H | Straightness and Flatness | 100 à 300 | ±0.2 |

| H | Straightness and Flatness | 300 à 1000 | ±0.3 |

| H | Straightness and Flatness | 1000 à 3000 | ±0.4 |

| H | Verticality | To 100 | ±0.2 |

| H | Verticality | 100 à 300 | ±0.3 |

| H | Verticality | 300 à 1000 | ±0.4 |

| H | Verticality | 1000 à 3000 | ±0.5 |

| H | Symmetry | To 100 | ±0.5 |

| H | Symmetry | 100 à 300 | ±0.5 |

| H | Symmetry | 300 à 1000 | ±0.5 |

| H | Symmetry | 1000 à 3000 | ±0.5 |

Precision CNC machining

In addition to universal tolerance CNC parts that comply with standards such as ISO2768M or ISO2768F, Yigu provides high-precision CNC machined parts.

À Yigu, we offer 3-axis and 5-axis CNC milling, CNC turning EDM、 Wire cutting and surface grinding services. We have extensive precision CNC machining services, an experienced team of experts, and accumulated rich experience in how to use 3-axis, 4-axe, and 5-axis CNC machines to complete various projects in the best way possible.

Complétez votre prototype personnalisé dans 5 mesures

From prototype custom to small batch production

rapid Prototype custom

Prototype customization is the process of creating a physical model of a product or part, typically using manufacturing techniques such as CNC machining.

The purpose of the prototype is to test and refine the design, and ensure that the product operates as expected.

A prototype can help identify any design defects or issues that may need to be addressed before being put into production.

Production de petits lots

Small batch manufacturing is a method of rapidly producing products, typically in quantities between 100 et 100000 pièces.

Yigu provides high-quality customized parts, y compris l'usinage CNC, moulage à vide, traitement de tôlerie, low-pressure infusion and other small batch manufacturing services.

This method allows companies to test their designs and products before mass production, reducing the risk of product failures and financial losses.

CNC Precision Machining for Application Industries

In a world driven by innovation and uncompromising quality, precision isn’t just a requirement—it’s the foundation. We deliver excellence through state-of-the-art CNC machining, serving a diverse spectrum of industries where accuracy, fiabilité, and performance are non-negotiable.

- Automobile Usinage CNC: À haute résistance, precision components that drive the future of mobility, from engine blocks to electric vehicle batteries.

- Aérospatial Usinage CNC: Mission-critical parts machined to the tightest tolerances, meeting rigorous standards for safety and performance in the skies and beyond.

- Médical Usinage CNC: Biocompatible, complex instruments and implants manufactured in validated environments for diagnostics, surgery, and patient care.

- Mécanique Usinage CNC: Robust and reliable parts that form the backbone of industrial machinery and automation systems.

- Moule Usinage CNC: High-precision molds and dies for injection molding, die-casting, and forming across countless manufacturing sectors.

- Énergie renouvelable Usinage CNC: Components for wind turbines, solar power systems, and hydropower that help build a sustainable future.

- Électronique & Électrique Usinage CNC: Intricate housings, chauffer, connecteurs, and semiconductors that power the digital world.

- Biens de consommation & Appliance Usinage CNC: Durable, esthétique, and high-volume parts that enhance everyday life in homes around the globe.

- Produits de sport Usinage CNC: Léger, high-performance components that give athletes the winning edge, from bicycles to professional equipment.

- Construction & Marin Usinage CNC: Résistant à la corrosion, heavy-duty parts built to withstand the harshest environments on land and at sea.

- Télécommunications Usinage CNC: Precision waveguides, enclos, and components that enable seamless global connectivity.

- Secteur de l'énergie Usinage CNC: Critical parts for oil, gaz, and nuclear power generation, engineered for extreme pressures and temperatures.

- Agricole Usinage CNC: Durable and efficient components that increase productivity and reliability in modern farming equipment.

Peu importe votre industrie, your challenge, or your design, we provide the manufacturing expertise to bring it to life.

Pourquoi nous choisir?

Technical strength

Nous avons 55 Machine-outils CNC, y compris 5 5-axe, 10 4-axe, et 40 3-axis CNC machine tools. Our factory provides grinding, coupe de fil, and electrical discharge machining equipment.

Fast delivery

We have powerful machining centers, so we can arrange production very flexibly to ensure that operations can meet constantly changing customer needs.

One stop solution provider

We can not only manufacture your prototypes and parts, but also provide a wide range of post-processing services based on them to help you bring your products to market. You can fully trust us.

Processus d'usinage

Our CNC machining processes include coupure laser, Couper à jet d'eau, coupure de plasma, flame cutting, routing, lathe machining, ennuyeux, broaching, hobbing, mise en forme, honing, reaming, thread machining, gear machining, EDM machining, perforation, mill-turning, polissage, swissing, usinage de précision, 3-axe, 4-axe, et multi-axis Usinage CNC.