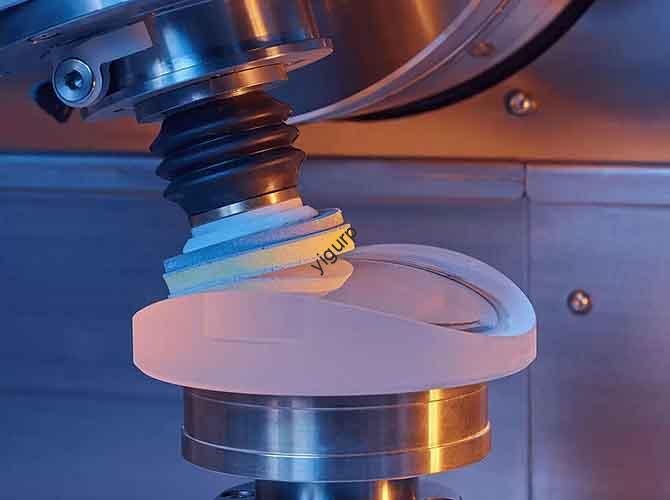

CNC Machining Male Threads: Master Precision for Industrial Fasteners

In mechanical manufacturing, pourquoi faire 95% of high-precision fastener producers rely on CNC machining male threads instead of traditional lathes? The answer lies in CNC’s ability to solve critical pain points—like inconsistent thread dimensions, production lente, and high tool wear—that plague manual or conventional threading. This article breaks down what CNC machining male threads is, […]