Pourquoi la conception par découpe laser CNC est-elle une compétence essentielle dans l'industrie?

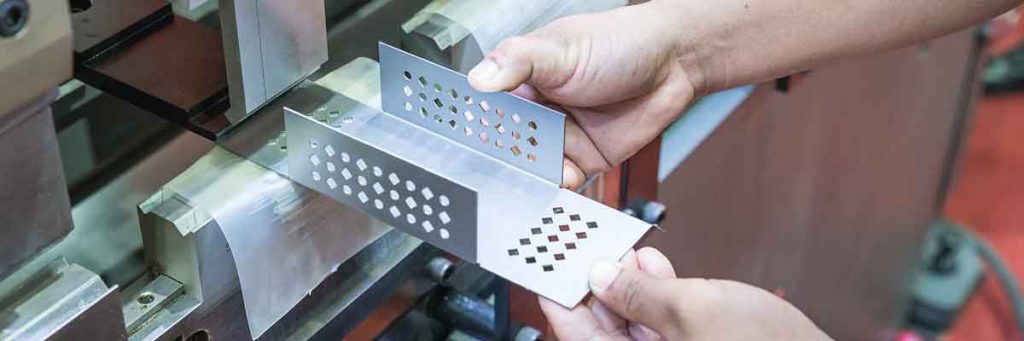

Dans divers domaines tels que la fabrication industrielle, conception artistique, et traitement des pièces automobiles, La découpe laser CNC est devenue la méthode de traitement dominante avec ses avantages de haute précision et d'efficacité.. Cependant, de nombreux utilisateurs rencontreront des problèmes tels que “coupe incomplète”, “bavures sur les bords”, et “erreurs d'importation de fichiers” en fonctionnement réel, et la raison principale […]