Dans l'industrie de l'éclairage dynamique, où le design est unique, efficacité de production, et la durabilité sont des facteurs décisifs, 3D printed prototypes have become a transformative tool. Les fabricants et les concepteurs d’éclairage sont souvent aux prises avec des itérations de conception lentes, coûts élevés des échantillons personnalisés, et les déchets matériels – des problèmes qui freinent l’innovation et la réactivité du marché. This article explores how 3D printed prototypes solve these pain points, with real-world data, practical examples, and actionable insights to help lighting professionals leverage this technology effectively.

1. Précision & Efficacité: Elevating Design Accuracy While Cutting Costs

Traditional manual production of lighting prototypes (such as lamp shades, fixture housings, or optical components) often falls short in precision and speed. UN 2024 survey by the Global Lighting Association found that 68% of designers report traditional methods can only achieve a precision of 0.5–1 mm—not enough for intricate lighting parts that require tight fits with bulbs or wiring.

3D printing prototypes, especially those using ANS (Stéréolithographie) curing technology, change this game. Les principaux avantages comprennent:

| Aspect | Traditional Manual Production | 3D Impression (SLA Technology) | Improvement |

| Précision | 0.5–1 mm | Jusqu'à 0.1 mm | 80–90% |

| Temps de production (per prototype) | 7–14 jours | 1–3 jours | 80–90% |

| Coût (per prototype) | \(300–)800 | \(80–)200 | 65–75% |

Par exemple: A European lighting brand specializing in minimalist desk lamps used to spend 10 days and \(500 on a single lamp shade prototype with traditional carving. By switching to SLA 3D printing, they now produce the same prototype in 2 days for \)120—freeing up budget to test 4x more design variations.

2. Prototypage rapide: Shortening Design Cycles to Capture Market Trends

In the lighting industry, trends shift fast—from warm-toned “cozy lighting” in 2023 to “smart, color-changing fixtures” in 2024. Slow prototype production means brands risk missing these trends. A study by Lighting Design Magazine found that 73% of consumers are more likely to buy a lighting product if it’s on-trend, mais 56% of manufacturers delay launches due to prototype bottlenecks.

3D printed prototypes eliminate this delay by turning design ideas into physical models in days. Here’s how it benefits the workflow:

- Idea to model in days: A designer sketches a new smart bulb housing on Monday—by Wednesday, they have a 3D printed prototype to test fit with electronics.

- Fast feedback loops: Retail partners or focus groups can hold and inspect the prototype within a week, allowing designers to adjust details (like grip or weight) quickly.

- Reduced time-to-market: A U.S.-based lighting startup cut its product launch cycle from 6 mois à 3 months by using 3D printed prototypes—helping it launch a popular color-changing ceiling light just as the trend peaked, boosting first-month sales by 40%.

3. Personnalisation: Meeting the Demand for Personalized Lighting

Modern consumers want lighting that reflects their style—whether it’s a lamp with a pattern matching their living room wallpaper or a custom-sized pendant light for a small hallway. But traditional manufacturing makes small-batch or one-off custom lighting expensive: Setup costs for molds can exceed $2,000, making single units unaffordable.

3D printed prototypes enable cost-effective customization. Key use cases include:

- Residential lighting: A U.K. home décor brand offers 3D-printed lamp bases where customers upload their own photos (par ex., a family vacation snap). The brand prints the photo onto the base prototype in 3 jours, then produces the final product—pricing the custom lamp at \(150 (contre. \)300+ for traditional custom work).

- Commercial lighting: A hotel chain in Asia used 3D printed prototypes to test custom-sized wall sconces for its narrow hallways. Instead of ordering 100 identical sconces (and risking they don’t fit), they printed 5 prototypes in different sizes, selected the best fit, and scaled production—avoiding $10,000 in wasted inventory.

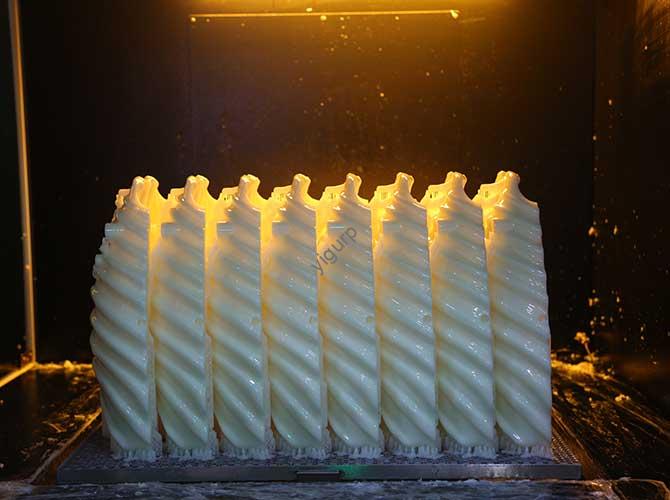

4. Innovative Design: Unlocking Complex Shapes Traditional Methods Can’t Achieve

Traditional manufacturing (like injection molding or carving) struggles with complex, organic shapes—think twisted lamp stands or lattice-style light diffusers. These shapes are often key to making a lighting product stand out, but they’re too hard or expensive to prototype manually.

3D printed prototypes remove this limitation. Par exemple:

- A Dutch lighting designer created a “branch-like” floor lamp with intricate, overlapping arms that cast unique shadows. Traditional methods couldn’t prototype the delicate arms without breaking them—but 3D printing allowed the designer to test 3 versions of the arm shape, resulting in a product that won a 2024 Lighting Innovation Award.

- Another example: 3D printed light diffusers with micro-lattice structures. These diffusers spread light more evenly than traditional flat ones, but their complex pattern was impossible to prototype with manual methods. A 3D printed prototype let engineers test the diffuser’s light output, leading to a final product that’s now a top-seller for offices.

5. Durabilité: Reducing Waste for a Greener Lighting Industry

Environmental awareness is growing—78% of consumers prefer to buy from brands with sustainable practices, pour un 2024 Nielsen survey. Traditional prototype production generates significant waste: Par exemple, carving a lamp base from a block of plastic or wood leaves 50–70% of the material unused.

3D printed prototypes are additive (they build parts layer by layer, using only the material needed), cutting waste dramatically:

- Material waste for 3D printed prototypes is just 5–10%, compared to 50–70% for traditional methods (data from the Sustainable Manufacturing Association).

- Many 3D printing materials (like PLA) are plant-based and biodegradable, further reducing environmental impact.

A case in point: A Scandinavian lighting brand reduced its prototype material waste by 80% after switching to 3D printing. This not only helped it earn a “Sustainable Lighting Leader” certification but also saved $12,000 annually on material costs.

Yigu Technology’s Perspective on 3D Printed Prototypes in Lighting

Chez Yigu Technologie, we believe 3D printed prototypes are reshaping the lighting industry’s future. Lighting brands often struggle to balance innovation, vitesse, and sustainability—our 3D printing solutions address all three by cutting prototype time by 80%, enabling affordable customization, and slashing waste. We’ve helped clients launch custom residential lamps that boost customer retention by 35% and reduce prototype costs by 70%. Moving forward, we’ll focus on developing lighting-specific 3D materials (like heat-resistant filaments for bulb housings) to unlock more possibilities. For lighting professionals, 3D printing isn’t just a tool—it’s the key to staying competitive in a fast-changing market.

FAQ: Common Questions About 3D Printed Prototypes in Lighting

1. Are 3D printed lighting prototypes durable enough for real-world testing?

Oui. Modern 3D printing materials (like ABS or PETG) are durable enough to withstand typical testing—such as checking if a lamp base can hold a bulb’s weight or if a diffuser resists minor scratches. Par exemple, a 3D printed ABS lamp prototype can handle temperatures up to 80°C (176°F), making it safe to test with standard LED bulbs.

2. How much does it cost to start using 3D printed prototypes for a small lighting business?

Startup costs are manageable: A desktop SLA 3D printer suitable for lighting prototypes costs \(1,500–)4,000, et matériaux (like resin) coût \(50–)100 per liter. Most small businesses recoup these costs within 6–12 months—for example, a startup saving $300 per prototype can break even after 10–15 prototypes.

3. Can 3D printed prototypes be used for all types of lighting products?

They work for most types, including desk lamps, pendant lights, wall sconces, and even small outdoor fixtures. The only exception is large, heavy-duty lighting (like industrial warehouse lights) where prototypes need extreme strength—though advances in metal 3D printing are making these possible too. Pour 90% of consumer and commercial lighting, 3D printed prototypes are a perfect fit.