Quand il s’agit de plastiques techniques, peu de matériaux offrent la même combinaison de polyvalence, durabilité, and affordability as Plastique ABS. Abréviation de Acrylonitrile Butadiène Styrène, ABS a gagné sa réputation de “difficile, dur, rigide” matériau qui répond aux exigences d’innombrables industries. Des pièces automobiles à l'électronique grand public, this thermoplastic polymer plays a crucial role in modern manufacturing. Dans ce guide, we’ll explore what makes ABS unique, its key properties, procédés de fabrication, and why it remains a top choice for engineers and designers worldwide.

Understanding ABS Plastic: Composition and Core Properties

ABS plastic is a copolymer blend of three monomers, each contributing unique characteristics to the final material:

- Acrylonitrile: Provides chemical resistance and heat stability

- Butadiene: Adds impact strength and toughness

- Styrene: Offers rigidity, transformabilité, et une finition de surface lisse

This combination creates a material with balanced properties that make it suitable for diverse applications. Let’s break down its key attributes:

General Performance Characteristics

ABS stands out for its practical everyday properties:

- Densité: Environ 1.05 g/cm³, making it lightweight yet substantial

- Water Absorption: Faible, typically less than 0.2% après 24 hours of immersion

- Bonding Capabilities: Excellent adhesion with other materials, allowing for easy printing, peinture, et revêtement

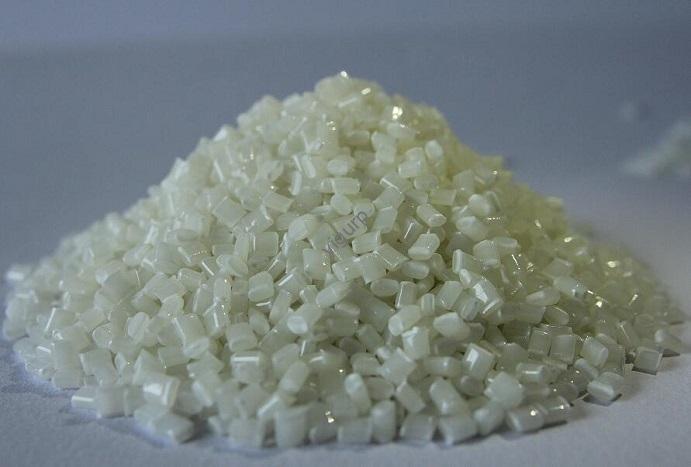

- Color Options: Available in natural (translucent ivory) or pre-colored variants, with excellent color retention

These general properties make ABS easy to work with and adaptable to various production needs.

Mechanical Strength and Durability

One of ABS’s greatest strengths is its impressive mechanical performance:

- Résistance aux chocs: Exceptionnel, even at low temperatures down to -40°C

- Résistance à l'usure: Excellent, supporting use in bearing applications under moderate loads

- Stabilité dimensionnelle: Maintains shape under normal operating conditions

- Oil Resistance: Performs well in contact with petroleum-based fluids

- Résistance à la traction: Typically 30–50 MPa, providing good structural integrity

These mechanical properties explain why ABS is chosen for parts that need to withstand daily use and occasional impacts, from children’s toys to automotive components.

Thermal Performance Range

ABS offers reliable performance across a practical temperature spectrum:

- Thermal Deformation Temperature: 93–118°C, which can increase by approximately 10°C after annealing

- Continuous Use Temperature Range: -40°C to 100°C

- Low-Temperature Toughness: Maintains some flexibility even at -40°C

- Point de fusion: Typically 200–240°C (392–464°F)

While not suitable for high-heat applications like engine compartments, ABS performs reliably in most consumer and industrial environments.

Electrical and Environmental Resistance

ABS provides practical protection and stability in various conditions:

- Isolation électrique: Good insulation properties that remain consistent across temperature and humidity changes

- Résistance chimique: Unaffected by water, inorganic salts, alcalis, and many acids

- Chemical Sensitivity: Soluble in ketones, aldehydes, and chlorinated hydrocarbons; susceptible to stress cracking from glacial acetic acid and vegetable oils

- Résistance aux intempéries: Poor UV stability—outdoor exposure for six months can reduce impact strength by 50%

These properties make ABS ideal for indoor applications but require additives or coatings for extended outdoor use.

Advantages and Disadvantages of ABS Plastic

Like any material, ABS has distinct strengths and limitations that engineers must consider during material selection:

Key Advantages of ABS

- Résistance aux chocs: Exceptional toughness that withstands drops and collisions, making it ideal for protective housings

- Rapport résistance/poids: Good structural strength without excessive weight

- Processing Versatility: Compatible with numerous manufacturing methods including injection molding, 3Impression D, et usinage

- Finition de surface: Easily achieves smooth, paintable surfaces suitable for consumer-facing products

- Rentabilité: Balances performance and price better than many engineering plastics

- Colorabilité: Takes colorants well and maintains consistent appearance in finished parts

Main Disadvantages of ABS

- UV Sensitivity: Degrades under prolonged sunlight exposure, requiring UV stabilizers for outdoor use

- Flammability: Classified as combustible with low fire resistance; releases toxic fumes when burned (though flame-retardant grades are available)

- Limited Heat Resistance: Deforms at relatively low temperatures compared to materials like polycarbonate

- Expansion thermique: Higher coefficient of thermal expansion than metals, making tight tolerances challenging across temperature ranges

Understanding these pros and cons helps designers maximize ABS’s benefits while mitigating its limitations.

Manufacturing Processes for ABS Plastic Parts

ABS’s popularity stems partly from its compatibility with diverse manufacturing methods. The choice of process depends on production volume, complexité de la pièce, and cost considerations:

Moulage par injection

The most common method for high-volume ABS production:

- Idéal pour: 10,000+ parts with complex geometries and tight tolerances

- Avantages: Haute efficacité, excellent repeatability, and minimal post-processing

- Typical Applications: Boîtiers pour appareils électroniques grand public, composants intérieurs automobiles, pièces de jouets

- Key Benefit: Ability to produce intricate details and consistent wall thicknesses

Usinage CNC

Ideal for low-volume production and prototyping:

- Idéal pour: 1–100 parts requiring precise dimensions and tight tolerances

- Avantages: No mold costs, délai d'exécution rapide, and excellent dimensional accuracy

- Typical Applications: Boîtiers personnalisés, composants mécaniques, prototypes fonctionnels

- Key Consideration: More material waste compared to molding processes

3D Impression

Revolutionizing rapid prototyping with ABS:

- Most Common Technology: Modélisation des dépôts fondus (FDM)

- Idéal pour: Prototypes, pièces personnalisées, et production en faible volume (1–50 pieces)

- Avantages: Design freedom for complex geometries, no tooling costs

- Limites: Layer lines may require post-processing for smooth finishes

- ABS-Like Alternatives: Available for SLA printers when finer details are needed

Other Manufacturing Methods

Additional processes suitable for specific applications:

- Extrusion: Produces continuous profiles like tubes, tiges, and sheets

- Moulage par soufflage: Creates hollow parts such as containers and automotive components

- Thermoformage: Shapes ABS sheets into large parts like trays, panels, and housings

| Manufacturing Method | Volume Range | Délai de mise en œuvre | Coût par pièce (Volume élevé) | Idéal pour |

| Moulage par injection | 10,000+ | 4–8 semaines (outillage) | Lowest | Complexe, pièces à grand volume |

| Usinage CNC | 1–100 | 1–5 jours | Highest | Prototypes, pièces personnalisées |

| 3D Impression | 1–50 | 1–3 jours | Haut | Prototypes complexes, petites pièces |

| Extrusion | 100+ | 1–2 semaines | Faible | Sheets, tubes, profiles |

| Thermoformage | 100–10 000 | 2–4 semaines | Modéré | Grand, shallow parts |

Major Applications of ABS Plastic Across Industries

ABS’s balanced properties make it indispensable across numerous sectors. Here’s where it’s most commonly used:

Industrie automobile

A major consumer of ABS plastic:

- Interior Components: Dashboards, tableaux de bord, door trim, steering wheel covers

- Exterior Parts: Grilles, boîtiers de rétroviseurs, bumper components, and ventilation systems

- Pièces fonctionnelles: Acoustic panels, door locks, and cable housings

- Avantage: Withstands cabin temperatures while providing impact resistance and aesthetic appeal

Electronique grand public

Dominates in device enclosures and components:

- Computing: Laptop and desktop housings, keyboard frames, mouse bodies

- Mobile Devices: Coques de téléphone, tablet covers, and accessory housings

- Home Electronics: TV bezels, télécommandes, audio equipment enclosures

- Propriétés clés: Isolation électrique, résistance aux chocs, and clean aesthetics

Appareils électroménagers

Found in numerous home devices:

- Kitchen Appliances: Blender bases, coffee maker housings, toaster exteriors

- Cleaning Equipment: Vacuum cleaner bodies, handle grips

- Climate Control: Air conditioner panels, heater housings

- Avantages: Chemical resistance to cleaning agents and durability for daily use

Toys and Recreation

A staple material in play products:

- Children’s Toys: Blocs de construction, figurines d'action, doll accessories

- Outdoor Equipment: Helmet shell,skateboard components, pièces de vélo

- Model Making: Ailes d'avion, scale models, hobby components

- Why ABS?: Safety, durabilité, and ability to be molded into intricate shapes

Dispositifs médicaux

Used in non-implantable medical equipment:

- Instrument Housings: Protective casings for medical devices

- Équipement de laboratoire: Sample containers, testing apparatus components

- Disposables: Some syringe components and medical tool handles

- Qualities: Résistance chimique, ease of sterilization, et durabilité

ABS contre. Similar Engineering Plastics

How does ABS compare to other common engineering plastics? Here’s a performance comparison:

| Propriété | ABS | Polystyrène (PS) | Polypropylène (PP) | Polycarbonate (PC) | Nylon (Pennsylvanie) |

| Résistance aux chocs | Excellent | Pauvre | Bien | Excellent | Excellent |

| Résistance à la chaleur | Modéré (93–118°C) | Faible (60–80°C) | Modéré (100–120°C) | Haut (120–140°C) | Haut (150–200°C) |

| Résistance chimique | Bien | Pauvre | Excellent | Modéré | Bien |

| Résistance aux UV | Pauvre | Pauvre | Bien | Modéré | Pauvre |

| Coût | Modéré | Lowest | Faible | Haut | Haut |

| Processabilité | Excellent | Excellent | Bien | Bien | Bien |

| Transparence | Opaque | Transparent | Translucent | Transparent | Opaque |

This comparison shows why ABS remains a top choice—it offers the best balance of impact resistance, transformabilité, and cost for many applications.

Tips for Working with ABS Plastic

To get the best results when designing or manufacturing with ABS, consider these expert recommendations:

Design Considerations

- Wall Thickness: Maintain 1–3mm for optimal strength; avoid sudden thickness changes

- Corners: Use radiused corners (minimum 0.5mm) to reduce stress concentrations

- Angles de dépouille: Include 1–2° draft for molded parts to facilitate easy ejection

- Ribs and Bosses: Reinforce with ribs (height ≤3× wall thickness) pour éviter la déformation

Processing Best Practices

- 3D Impression: Use heated build plates (100–110°C) and enclosed chambers to prevent warping

- Moulage: Maintain melt temperatures between 220–250°C for optimal flow

- Usinage: Use sharp tools and moderate feed rates to avoid melting

- Post-traitement: Easily accepts painting, placage, and bonding with cyanoacrylate adhesives

Mitigating Limitations

- UV Exposure: Add UV stabilizers or apply protective coatings for outdoor use

- Heat Sensitivity: Avoid applications with continuous temperatures above 80°C

- Flammability: Specify flame-retardant grades (UL94V0) pour applications électriques

- Stabilité dimensionnelle: Design with thermal expansion in mind for precision applications

Yigu Technology’s Perspective

Chez Yigu Technologie, we recognize ABS as a foundational material in rapid prototyping and production. Its unique balance of strength, transformabilité, and cost makes it indispensable for bridging prototype and production. We leverage ABS in vacuum molding and CNC machining for functional prototypes that accurately simulate final products. When paired with proper design considerations, ABS consistently delivers reliable performance across our clients’ most demanding applications.

FAQ

1. Is ABS plastic food-safe?

While general-purpose ABS isn’t certified food-safe, specific food-grade ABS formulations are available. These meet FDA standards for food contact, though they’re less common than food-safe alternatives like PP or HDPE. Always verify certification for food applications.

2. Can ABS plastic be recycled?

Oui, ABS is technically recyclable ( resin identification code #7). Cependant, it’s not as widely recycled as PET or PP. Many industrial facilities accept post-industrial ABS scrap, but consumer recycling programs vary by location. Recycled ABS may have slightly reduced mechanical properties.

3. How does ABS hold up in outdoor applications?

Unmodified ABS performs poorly outdoors due to UV degradation. Cependant, adding UV stabilizers or applying protective coatings can extend its outdoor lifespan to 1–3 years. For longer outdoor use, consider more UV-resistant materials like PP or PC blended with ABS.