The success of any 3D printing project hinges on choosing the right material—and with so many options available, compréhension 3D printing materials features est critique. Du PLA biodégradable pour les prototypes écologiques au titane haute résistance pour les pièces aérospatiales, chaque matériau possède des caractéristiques uniques qui le rendent idéal pour des tâches spécifiques. This guide breaks down the key features of the most popular 3D printing materials, groups them by category (plastiques, métaux, biomaterials, emerging options), and provides actionable tips to help you pick the perfect material for your project. Whether you’re a hobbyist printing a desk organizer or an engineer developing medical devices, this guide eliminates guesswork and ensures your prints meet performance and design goals.

1. Matières plastiques: The Most Versatile 3D Printing Option

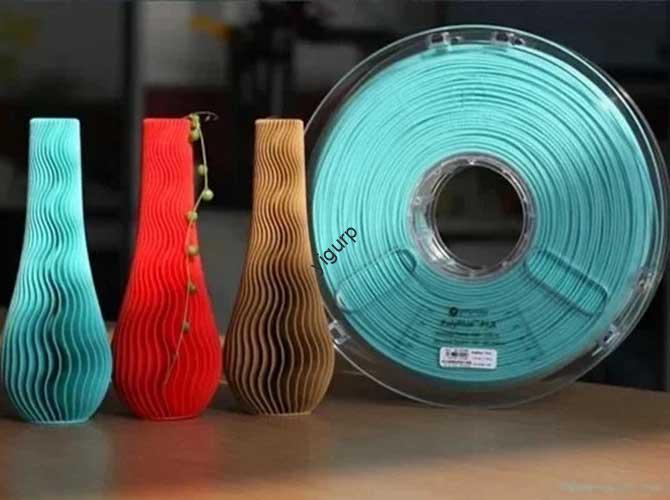

Plastics are the backbone of 3D printing—affordable, facile à utiliser, and available in a range of properties. They’re ideal for prototypes, pièces fonctionnelles, and decorative items, with features tailored to everything from outdoor durability to flexibility.

Key Features of Common 3D Printing Plastics

| Matériel | Core Features | Force & Durabilité | Applications idéales | Avantages & Inconvénients |

| ABS (Acrylonitrile Butadiène Styrène) | Excellent résistance aux chocs; high surface hardness; bonne résistance chimique (resists oils, détergents). | Résistance à la traction: 40–50MPa; Résistance aux chocs Izod: 20–30 J/m. Durable for repeated use but prone to warping. | Pièces automobiles (mirror covers, boîtiers de capteurs); outillage industriel (jigs, clamps); jouets (durable action figures). | ✅ Strong and chemical-resistant; ✖️ High shrinkage rate (5–8%), prone to warping; emits fumes during printing. |

| PLA (Acide polylactique) | Made from renewable resources (cornstarch, canne à sucre); biodégradable (breaks down in 6–24 months); smooth surface finish; clear detail reproduction. | Résistance à la traction: 50–70 MPa; rigid but brittle under impact. | Eco-friendly prototypes (packaging samples); objets de décoration (des vases, figurines); modèles éducatifs (formes géométriques). | ✅ Easy to print (no warping); écologique; ✖️ Low heat resistance (melts at 50–60°C); fragile (breaks under heavy stress). |

| PETG (Polyéthylène téréphtalate glycol) | Excellent résistance aux intempéries (withstands UV, pluie, et les variations de température); low shrinkage rate (2–4%); good water resistance; moderate flexibility. | Résistance à la traction: 55–75 MPa; more durable than PLA; resists bending and cracking. | Outdoor gear (jardinières, bike fenders); pièces fonctionnelles (coques de téléphone, bouteilles d'eau); coffrets électriques (boîtiers de capteurs). | ✅ Balances strength and flexibility; imperméabiliser; ✖️ Slightly harder to print (needs precise temperature control); sticks tightly to beds. |

| TPU (Polyuréthane thermoplastique) | Extrême élasticité (stretches up to 300% of its original length); good abrasion resistance; doux, rubber-like texture. | Résistance à la traction: 30–60 MPa; highly flexible but less rigid than PLA/ABS. | Wearable devices (bracelets de montre, fitness trackers); poignées (poignées d'outils, télécommandes); protective parts (coques de téléphone, laptop bumpers). | ✅ Flexible and shock-absorbent; ✖️ Slow print speed (prone to stringing); needs heated bed (40–50°C) pour l'adhésion. |

Real-World Example: A small business wanted to print outdoor planters that would withstand rain and UV rays. PLA planters faded and cracked after 3 months outside, but PETG planters (with their weather-resistant features) stayed intact for 2 years—proving how material features directly impact performance.

2. Metallic Materials: For High-Strength, Industrial-Grade Parts

Metallic 3D printing materials are reserved for applications where strength, résistance à la chaleur, and durability are non-negotiable. They’re more expensive and require specialized printers (GDT, DMLS), but their features make them irreplaceable in aerospace, automobile, et industries médicales.

Key Features of 3D Printing Metals

| Matériel | Core Features | Force & Résistance à la chaleur | Applications idéales | Pourquoi il se démarque |

| Acier inoxydable | Excellent résistance à la corrosion (resists rust and chemicals); résistance à haute température (up to 870°C); bonne soudabilité. | Résistance à la traction: 500–700 MPa; retains strength at high temperatures. | Pièces de machines industrielles (vannes, pompes); composants marins (boat hardware); outils médicaux (instruments chirurgicaux). | Balances corrosion resistance and strength—perfect for harsh environments (saltwater, produits chimiques). |

| Alliage d'aluminium | Léger (densité: 2.7 g/cm³—1/3 the weight of steel); rapport résistance/poids élevé; bonne conductivité thermique. | Résistance à la traction: 300–500 MPa; lightweight but strong enough for structural use. | Pièces aérospatiales (cadres de drones, supports d'avion); composants automobiles (lightweight engine parts); électronique (dissipateurs de chaleur). | Reduces weight without sacrificing strength—critical for fuel efficiency in aerospace/automotive. |

| Alliage de titane | Ultra-high strength-to-weight ratio; biocompatible (safe for human body); excellente résistance à la corrosion; withstands extreme temperatures (-250°C à 600°C). | Résistance à la traction: 800–1,200 MPa; stronger than steel but 40% plus léger. | Implants médicaux (arthroplasties du genou, couronnes dentaires); pièces aérospatiales (pales de turbine, rocket components); high-performance sports gear (cadres de vélo). | Biocompatibility and extreme strength make it the gold standard for medical and aerospace applications. |

Étude de cas: A medical device company used titanium alloy to 3D print knee implants. The material’s biocompatibility meant it didn’t trigger immune reactions, and its strength ensured the implants lasted 15+ years—far longer than plastic alternatives. For life-critical parts, metallic materials’ features are non-negotiable.

3. Biomaterials: For Medical and Eco-Conscious Applications

Biomaterials are a specialized category of 3D printing materials designed to interact safely with living organisms or degrade naturally. Their features focus on biocompatibility, biodegradability, and mimicry of human tissues—making them ideal for medical devices and sustainable products.

Key Features of 3D Printing Biomaterials

| Matériel | Core Features | Biocompatibilité & Degradability | Applications idéales | How It Solves Problems |

| Bioactive Glass | Mimics the chemical composition of human bone; promotes tissue regeneration (bonds with bone cells over time); biodégradable (breaks down as new tissue grows). | Fully biocompatible (no immune response); degrades gradually over 6–12 months. | Bone grafts (spinal fusion, fracture repair); implants dentaires (tooth root replacements); wound dressings (releases healing ions). | Eliminates the need for second surgeries to remove implants—biodegrades as the body heals. |

| Hydroxyapatite | Main mineral component of human bone and teeth; excellent biocompatibilité (integrates with surrounding tissue); slow biodegradation (lasts 1–2 years). | Résistance à la traction: 100–150 MPa; matches bone density. | Dental fillings (natural-looking, biocompatible); échafaudages osseux (supports new bone growth); cosmetic surgery (facial implants). | Reduces rejection risk—body recognizes it as “natural” tissue; no toxic byproducts during degradation. |

Pro Tip: Always verify biomaterials’ certification (par ex., FDA approval for medical use)—not all “bio” labeled materials meet safety standards for human contact.

4. Emerging Materials: Pushing the Boundaries of 3D Printing

New 3D printing materials are constantly being developed, offering innovative features that expand what’s possible. From lightweight composites to conductive plastics, these materials are transforming industries like aerospace, électronique, et énergies renouvelables.

Key Features of Emerging 3D Printing Materials

| Matériel | Core Features | Performance Highlights | Applications idéales | Future Potential |

| Carbon Fiber Reinforced Polymers (CFRP) | Combines plastic (PLA, PETG) with carbon fiber; lightweight and ultra-strong (strength-to-weight ratio better than steel); faible dilatation thermique (stable at high temps). | Résistance à la traction: 150–300 MPa; 50% lighter than steel parts. | Composants aérospatiaux (drone wings, pièces satellites); racing gear (cadres de vélo, helmet shells); outils industriels (heavy-duty clamps). | Will replace metal in more applications as costs drop—critical for electric vehicles (reducing weight = extending range). |

| Matériaux conducteurs | Embedded with conductive particles (carbon nanotubes, argent); transmits electricity; compatible with 3D printing (no special equipment needed for basic use). | Conductivité électrique: 1–100 S/m (varies by particle concentration); flexible options available. | Electronic prototypes (sensor pads, cartes de circuits imprimés); wearable tech (smart gloves, fitness trackers); antennes (petit, custom-shaped). | Enables “printed electronics”—devices where circuits are 3D printed directly onto parts, reducing assembly time. |

Exemple: A startup developing a smart gardening sensor used conductive PETG to print the sensor’s housing. The material transmitted data (moisture levels) without needing separate wires—simplifying design and cutting production costs by 40%. Emerging materials like this blur the line between “part” and “function.”

5. How to Choose the Right 3D Printing Material

With so many materials available, use this step-by-step framework to narrow down your options based on your project’s needs:

Étape 1: Define Your Project’s Core Requirements

Ask yourself:

- What will the part do? (par ex., hold weight, withstand heat, flex)

- Where will it be used? (par ex., outdoors, in the human body, on a desk)

- What’s your budget? (plastiques: \(15–)50/kilos; métaux: \(100–)500/kilos)

Étape 2: Match Requirements to Material Features

| Requirement | Material Recommendation | Pourquoi ça marche |

| Eco-Friendly | PLA | Biodégradable, made from renewable resources. |

| Outdoor Durability | PETG, ABS | Weather-resistant, Stable aux UV. |

| Haute résistance | Carbon Fiber Reinforced Polymers, Alliage de titane | Ultra-résistant, haute résistance à la traction. |

| Usage médical | Alliage de titane, Hydroxyapatite | Biocompatible, safe for human body. |

| Flexibilité | TPU | Élastique, stretches without breaking. |

Étape 3: Test Before Scaling

Always print a small sample (par ex., a 5cm x 5cm square) to test material features:

- For strength: Bend or apply pressure to the sample—does it hold up?

- For weather resistance: Leave the sample outside for a week—does it fade or crack?

- For biocompatibility: (Medical use only) Test with cell cultures or consult a certification body.

Yigu Technology’s Perspective

Chez Yigu Technologie, we help clients across industries match 3D printing materials to their needs. For beginners, we recommend PLA (facile à imprimer) or PETG (versatile for indoor/outdoor use). Pour les clients industriels, carbon fiber composites cut weight by 30% contre. métal, while titanium alloy meets aerospace/medical standards. The biggest mistake we see? Overlooking material features like heat resistance—e.g., using PLA for a car’s engine bay part (it melts!). We always guide clients to prioritize performance first: un \(50/kg material that works is cheaper than a \)15/kg material that fails. As new materials emerge, we’ll keep integrating them to help clients innovate faster.

FAQ

- Which 3D printing material is best for beginners?

PLA is ideal—it’s easy to print (no warping), abordable (\(15–)30/kilos), and forgiving of imperfect settings. You’ll get smooth, detailed prints with minimal effort—perfect for learning the basics.

- Can I use plastic materials for outdoor projects?

Oui, but choose PETG or ABS. PETG has better weather resistance (Stable aux UV, étanche) and lower shrinkage than ABS. Avoid PLA—it fades and becomes brittle in sunlight/rain within 3–6 months.

- Are metallic 3D printing materials worth the cost?

For high-performance applications (aérospatial, médical), yes—they offer strength and durability no plastic can match. For hobbyists or low-stress parts, plastics are more cost-effective. A titanium medical implant (\(500–)1,000) dure 15+ années, while a plastic alternative ($50) may need replacement every 2–3 years.