If you’re tackling high-pressure oil and gas projects, heavy-duty construction, or demanding engineering tasks, you need a steel that can keep up.X70 pipeline structural steel is exactly that—it’s a high-strength solution trusted for its durability, versatilidad, and reliability in tough conditions. This guide will break down everything you need to choose, usar, and get the most out of X70 steel for your next project.

1. Material Properties of X70 Pipeline Structural Steel

X70’s performance starts with its carefully designed properties. Let’s break them into clear categories to make it easy to understand.

Composición química

Elchemical composition of X70 is optimized to balance strength, tenacidad, and workability—following global standards like API 5L. Here’s a typical breakdown:

| Element | Content Range (wt%) | Key Role |

|---|---|---|

| Carbon (do) | 0.22 máximo | Boosts strength without making the steel too brittle for welding/forming |

| Manganese (Mn) | 1.70 máximo | Enhances toughness and improves weldability |

| Silicio (Y) | 0.40 máximo | Removes oxygen during steelmaking (prevents defects in the final product) |

| Phosphorus (PAG) | 0.025 máximo | Strictly limited (low levels avoid brittleness in cold weather) |

| Sulfur (S) | 0.010 máximo | Minimized to prevent cracking during rolling or welding |

| Chromium (cr) | 0.50 máximo | Mejora la resistencia a la corrosión (critical for underground/marine pipelines) |

| Molibdeno (Mes) | 0.25 máximo | Increases high-temperature strength (ideal for hot oil pipelines) |

| Níquel (En) | 0.30 máximo | Boosts low-temperature toughness (works in freezing regions like Alaska) |

| Vanadium (V) | 0.08 máximo | Refines grain structure for better overall mechanical performance |

Physical Properties

These traits affect how X70 behaves in real-world scenarios—from weight calculations to temperature changes:

- Densidad: 7.85 gramos/cm³ (same as most structural steels, so it’s easy to estimate project weight)

- Punto de fusión: ~1450–1520°C (compatible with standard steel manufacturing processes)

- Conductividad térmica: 43 W/(m·K) (spreads heat evenly, reducing stress during welding)

- Thermal expansion coefficient: 13.3 × 10⁻⁶/°C (low enough to avoid warping in extreme heat or cold)

- Electrical resistivity: 0.19 × 10⁻⁶ Ω·m (not used for electrical parts, but useful for safety planning)

Propiedades mecánicas

X70’s mechanical strength is what makes it a top choice for high-pressure projects. Here are its key traits:

- Resistencia a la tracción: 570–720 MPa (can handle intense pulling forces without breaking)

- Yield strength: Minimum 483 MPa (stays strong even when stretched—vital for high-pressure pipelines)

- Dureza: 180–210 HB (resists wear from soil, fluids, or moving parts)

- Impact toughness: ≥ 45 J at -40°C (performs reliably in freezing climates)

- Ductilidad: ≥ 18% alargamiento (can bend or form into pipes without cracking)

- Fatigue resistance: Excellent for repeated stress (ideal for vibrating pipeline components or machine parts)

- Fracture toughness: Alto (prevents sudden, catastrophic failure in oil/gas lines)

Other Key Properties

- Good weldability: Works with common methods like MIG, TIG, and stick welding—no special equipment needed, saving time on projects.

- Good formability: Can be hot-rolled into large pipes, cold-bent into structural shapes, or forged into custom parts.

- Resistencia a la corrosión: Holds up well in soil, fresh water, and mild chemicals (add a coating for harsh environments like saltwater).

- Toughness: Maintains strength in extreme temperatures—from -40°C (freezing) to 65°C (hot deserts).

2. Applications of X70 Pipeline Structural Steel

X70 isn’t just for pipelines—it solves problems across multiple industries. Here’s how it’s used in real-world projects:

Pipeline Industry

El #1 use forX70 pipeline structural steel esoil and gas pipelines. Its high yield strength and corrosion resistance make it perfect for transporting high-pressure crude oil, natural gas, and refined fuels over long distances.

Estudio de caso: A major energy company used X70 steel for a 2,000 km natural gas pipeline in Canada. The pipeline had to handle 12 MPa of pressure and survive -35°C winter temperatures. Después 10 años, inspections showed zero leaks or corrosion (thanks to a 3-layer polyethylene coating) and no signs of stress—proving X70’s reliability in harsh northern conditions.

Construction Industry

In construction, X70 is used for heavy-duty structural needs:

- Structural steel components (supports for industrial factories)

- Beams y columnas (for long-span bridges and high-rise buildings)

- Building frames (for power plants and warehouses)

Why X70? It’s stronger than lower-grade steels (like X52 or X65) but more cost-effective than ultra-high-strength options. Por ejemplo, a highway bridge in Brazil used X70 beams to span 50 meters without extra supports. Después 7 años, the beams showed no bending or wear—even with heavy truck traffic.

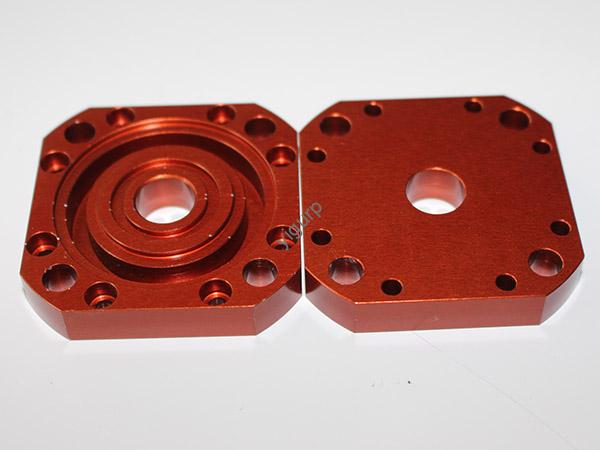

Ingeniería Mecánica

Mechanical engineers rely on X70 for parts that need extreme strength:

- Engranajes (es dureza y resistencia a la fatiga prevent wear from constant movement)

- Ejes (handles high rotational stress in industrial pumps and motors)

- Machine parts (durable for heavy equipment like mining conveyors)

A mining company switched to X70 for its conveyor shafts. The X70 shafts lasted 5x longer than the mild steel shafts they replaced—cutting downtime by 40%.

Industria Marina

X70 works well in saltwater and offshore environments:

- Ship structures (hulls and deck supports for large cargo ships)

- Offshore platforms (legs and braces for deep-sea oil rigs)

Estudio de caso: An offshore oil platform in the North Sea used X70 steel for its support legs. The steel was coated with zinc-aluminum alloy to boost corrosion resistance. Después 15 años, the legs showed only minor rust—far better than the 8-year lifespan of the previous carbon steel legs.

Agricultural Machinery

Farmers use X70 for heavy-duty equipment that faces rough terrain:

- Tractor parts (frames and engine blocks for large farm tractors)

- Arados y harrows (resist wear from rocks and hard soil)

A farm equipment maker tested X70 plows against standard steel plows. The X70 plows lasted 3 growing seasons (vs. 1 for standard steel) and required fewer repairs—saving farmers thousands in replacement costs.

3. Manufacturing Techniques for X70 Pipeline Structural Steel

Making X70 steel requires precise steps to ensure it meets API 5L standards. Here’s a breakdown of the process:

Steelmaking Processes

Two main methods produce X70, depending on volume and raw materials:

- Basic Oxygen Furnace (BOF): The most common method for large-scale production. It uses molten iron (from a blast furnace) and blows oxygen into it to remove impurities. Alloying elements (like Mn and Mo) are added to hit X70’s chemical specs. Fast and cost-effective for mass-produced pipelines.

- Electric Arc Furnace (EAF): Uses electricity to melt scrap steel. Great for smaller batches or custom orders (p.ej., specialized X70 parts for machinery). More flexible but slightly slower than BOF.

Tratamiento térmico

Heat treatment fine-tunes X70’s mechanical properties:

- Normalizing: Heats the steel to 870–970°C, then cools it in air. Improves ductility and makes the steel’s structure uniform (good for parts that need bending).

- Quenching and Tempering: Heats to 910–960°C, quenches (cools quickly) in water or oil, then tempers (reheats) to 560–660°C. This process boosts yield strength y tenacidad—critical for high-pressure pipelines.

- Recocido: Heats to 810–860°C, cools slowly in a furnace. Reduces stress from forming (used for precision parts like gears).

Forming Processes

X70 is shaped into final products using these methods:

- laminación en caliente: Heats the steel to 1100–1250°C, then rolls it through machines to make pipes, vigas, or sheets. Fast and ideal for large-volume pipeline production.

- laminación en frío: Rolls the steel at room temperature. Creates smoother surfaces and tighter dimensions (used for precision parts like shafts).

- Forja: Hammers or presses hot steel into complex shapes (p.ej., custom machine parts). Improves strength by aligning the steel’s grain structure.

- Extrusión: Pushes heated steel through a die to make tubes or hollow parts (used for small-diameter pipelines).

- Estampado: Uses presses to cut or bend flat steel into parts like brackets (common in construction).

Tratamiento superficial

To boost corrosion resistance and lifespan, X70 gets these surface treatments:

- galvanizado: Dips the steel in molten zinc. Creates a protective layer that prevents rust (dura 25+ años al aire libre).

- Cuadro: Applies epoxy or polyurethane paint. Ideal for above-ground pipelines or structural parts.

- Shot blasting: Blasts the steel with tiny metal balls to remove rust, escala, or dirt. Prepares the surface for coating.

- Revestimiento: Uses fusion-bonded epoxy (FBE) or 3-layer polyethylene (3LPE) for pipelines. These coatings resist chemicals, soil, and saltwater—extending the steel’s life by 40+ años.

4. X70 Pipeline Structural Steel vs. Other Materials

How does X70 compare to other common materials? Let’s break it down to help you choose the right option.

X70 vs. Carbon Steels (p.ej., A36)

| Factor | X70 Pipeline Structural Steel | Acero al carbono suave (A36) |

|---|---|---|

| Yield Strength | 483 MPa min | 250 MPa min |

| Toughness | Excelente (-40°C) | Bien (0°C only) |

| Soldabilidad | Bien | Very Good |

| Cost-Performance | Better for high-pressure projects | Cheaper for light use (p.ej., esgrima) |

| Mejor para | Oil/gas pipelines, puentes de gran luz | Small buildings, piezas no críticas |

X70 vs. High-Strength Low-Alloy (HSLA) Steels (p.ej., X80)

- Composición química: X80 has more alloying elements (p.ej., niobium, titanio) than X70, making it stronger.

- Propiedades: X80 has a higher yield strength (551 MPa min) but is less ductile than X70. X70 is easier to form and weld.

- Aplicaciones: X80 is for ultra-high-pressure pipelines; X70 is better for most standard high-pressure projects (more cost-effective and easier to work with).

X70 vs. Stainless Steels (p.ej., 304)

| Factor | X70 Pipeline Structural Steel | Acero inoxidable (304) |

|---|---|---|

| Resistencia a la corrosión | Bien (con revestimiento) | Excelente (no coating) |

| Yield Strength | 483 MPa min | 205 MPa min |

| Costo | Más bajo ($1.20–$1.70/lb) | Más alto ($3.00–$4.00/lb) |

| Mejor para | High-pressure pipelines | Food processing, equipo medico |

X70 vs. Aleaciones de aluminio (p.ej., 6061)

- Peso: El aluminio es 1/3 the weight of X70 (great for aircraft), but X70 is 2.5x stronger.

- Resistencia a la corrosión: Aluminum resists rust better, but X70 (con revestimiento) handles soil and oil better.

- Costo: X70 is cheaper than high-grade aluminum (saves money on large projects like pipelines).

- Fabricación: Aluminum is easier to cut, but X70 is better for high-temperature or high-pressure uses.

5. Yigu Technology’s Perspective on X70 Pipeline Structural Steel

En Yigu Tecnología, we’ve supported dozens of clients in usingX70 pipeline structural steel for high-stakes projects—from cross-country pipelines to offshore platforms. We see X70 as a “sweet spot” material: it offers the high strength needed for 10+ MPa pipelines while keeping weldability and formability intact. For oil and gas clients, X70’s cold-temperature toughness (-40°C) solves the problem of winter-related brittleness. For construction clients, it’s a cost-effective upgrade from lower grades, cutting the need for extra supports. We also optimize X70’s manufacturing—using BOF for large pipeline orders and EAF for custom parts—to meet tight deadlines. Overall, X70 is our top recommendation for projects that need strengthy flexibilidad.

FAQ About X70 Pipeline Structural Steel

1. Can X70 pipeline structural steel be used for offshore pipelines?

Sí! X70 works perfectly for offshore pipelines when paired with a corrosion-resistant coating (like 3LPE). Estenacidad handles wave stress, and the coating prevents saltwater rust. We’ve supplied X70 for offshore projects in the Gulf of Mexico that have lasted 12+ years with no issues.

2. Do I need special equipment to weld X70 steel?

No—X70 hasbuena soldabilidad and works with standard welding equipment (MIG, TIG, stick). The only tip: use low-hydrogen electrodes to avoid weld cracking, especially in humid weather. Most fabricators don’t need extra training to weld X70.

3. How long does X70 steel last in underground pipelines?

With a proper coating (like FBE), X70 can last 35–50 years underground. Without a coating, it lasts 20–25 years (depending on soil moisture). We recommend ultrasonic inspections every 5 years to catch small issues early and extend its life even further.