Power prototype machining refers to the specialized manufacturing processes used to create physical prototypes of power modules (p.ej., chargers, adapters, lithium battery protection boards). These processes validate design feasibility, estabilidad estructural, and functional performance—critical for reducing risks in electronic product development. Unlike general prototype machining, power prototype machining prioritizes precision for heat dissipation, component compatibility, and safety compliance (p.ej., voltage insulation). This article breaks down its core machining methods, flujos de trabajo paso a paso, selección de materiales, troubleshooting, and real-world applications to guide teams toward successful prototype creation.

1. What Are the Core Machining Methods for Power Prototypes?

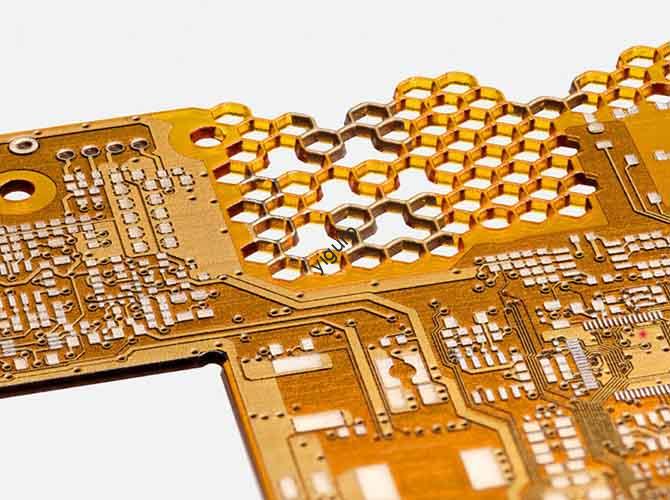

Each method is tailored to specific power prototype needs—from complex shell shapes to high-precision metal components. The table below compares their key traits, aplicaciones, and advantages.

| Machining Method | Core Characteristics | Flujo de trabajo paso a paso | Applicable Power Prototype Types | Ventajas clave |

| 3D Printing Machining | – Layer-by-layer deposition of plastic/resin.- Soportes estructuras huecas y complex curves (p.ej., custom charger shells).- Materiales: PLA (bajo costo), ABS (alta resistencia), resina (alta precisión). | 1. Use SolidWorks/UG to design the power enclosure (include heat dissipation holes, interface cutouts).2. Export the model as an STL file; use slicing software (Tratamiento) to set parameters: – Layer height: 0.1–0,2 mm (higher precision for resin). – Infill: 20–30% (structural stability without excess weight). – Soportes: Add for overhangs (p.ej., USB-C interface lips).3. Print with FDM (PLA/ABS) o SLA (resina).4. Post-process: Remove supports, sand with 200→800 grit sandpaper, and polish resin parts for smoothness. | – Consumer power supplies (portable chargers, phone adapters).- Customized power housings (non-standard shapes for IoT devices).- Small-batch prototypes (1–10 units for design verification). | – Rapid turnaround (4–24 hours per prototype).- Low upfront cost (no mold required).- Ideal for iterative design (easy to modify and reprint). |

| Mecanizado CNC | – Computer-controlled cutting of solid materials (metal/plastic).- Precisión ultraalta (tolerancia: ±0,05 mm) para heat dissipation modules y metal enclosures. | 1. Convert 3D models to G-code using CAM software (cámara maestra).2. Secure the material block (aleación de aluminio, POM, acrílico) to the CNC machine bed.3. Set cutting parameters: – Velocidad del husillo: 10,000–15.000 rpm (higher for metal, lower for plastic). – Tasa de alimentación: 500–1000mm/min (adjust to avoid material melting). – Cutting depth: 0.1–0.5mm per pass (prevents tool breakage).4. Machine the part (drill holes, carve shells, mill heat dissipation fins).5. Post-process: Deburr with a file, sandblast aluminum parts for texture, and polish acrylic for transparency. | – Industrial power supplies (high-power modules for factories).- Metal enclosures (aluminum alloy chargers for outdoor use).- Precision components (disipadores de calor, PCBA mounting brackets). | – Superior structural strength (suitable for load-bearing parts).- Excellent surface finish (supports plating, anodizado).- Matches mass production material properties (critical for functional testing). |

| Silicone Duplicate Machining | – Mold-based replication using a master prototype (3D-printed/CNC-machined).- Cost-effective for soft shells y producción en lotes pequeños (10–50 unidades). | 1. Create a master prototype (p.ej., 3D-printed resin power shell).2. Build a mold box around the master; pour liquid silicone (viscosity 500–2000 cP) and add vent holes to release air.3. Cure the silicone mold at 25–80°C for 4–24 hours.4. Demold the master; inject PU resin, epoxy, or silicone into the mold.5. Cure the replicated part, then trim excess material (gate marks) and sand edges. | – Soft power grips (rubberized handles for industrial chargers).- Flexible enclosures (waterproof power modules for outdoor gear).- Low-cost trials (validating design before CNC/3D printing large batches). | – Low per-unit cost (\(3–)15 por parte).- Preserves master details (p.ej., texture on silicone grips).- Fast replication (3–5 days per batch). |

2. What Is the Step-by-Step Design & Machining Workflow for Power Prototypes?

The workflow integrates design validation, mecanizado, and testing to ensure the prototype meets electronic product standards.

2.1 Paso 1: Preparación del diseño (Lay the Foundation)

Design decisions directly impact machining feasibility and power performance.

| Design Stage | Key Tasks | Power-Specific Considerations |

| ID Design | Define the power supply’s shape (cuboid, cilíndrico), interface type (USB-C, DC port), heat dissipation hole layout, and indicator light position. | – Heat dissipation holes: Use mesh patterns (≥1mm diameter) to prevent dust accumulation while maximizing airflow.- Interface placement: Ensure USB ports are centered and aligned with internal PCBA connectors (avoid misalignment during assembly). |

| MD Design | Design internal structures: battery compartment size, PCBA fixed positions (screw holes, snap fits), y ángulos de tiro (≥1° for CNC-machined plastic parts). | – Screw hole placement: Space holes 20–30mm apart for even PCBA support.- Draft angles: Critical for CNC machining—prevents parts from sticking to cutting tools and reduces post-processing time. |

| DFMEA Analysis | Evaluate potential risks: assembly gaps, insufficient heat dissipation, electromagnetic interference (EMI), and short-circuit hazards. | – Heat dissipation: Simulate temperature distribution (use software like ANSYS) to ensure no component exceeds 85°C (standard for power modules).- EMI protection: Design shielding compartments for transformers to avoid interfering with nearby electronics. |

2.2 Paso 2: Ejecución de mecanizado (Produce the Prototype)

Select the method based on the prototype’s purpose (appearance vs. función) y tamaño del lote.

| Guión | Recommended Machining Method | Rationale | Ejemplo |

| Appearance Verification (1–5 units) | 3Impresión D (Resina) | Rápido, captura detalles finos (p.ej., silk-screened voltage labels), bajo costo. | A resin prototype of a 20W phone charger to test shell shape and button placement. |

| Pruebas funcionales (5–20 units) | Mecanizado CNC (Aluminum Alloy/POM) | Alta precisión, durable for repeated testing (p.ej., plugging/unplugging cables). | A CNC-machined aluminum prototype of a lithium battery protection board to test voltage output stability. |

| Small-Batch Trial (20–50 unidades) | Silicone Duplicate (PU Resin) | Low per-unit cost, replicates master details (p.ej., heat dissipation fins). | 30 PU resin prototypes of an IoT device power module for customer feedback. |

2.3 Paso 3: Tratamiento superficial (Enhance Performance & Estética)

Surface treatment improves durability, seguridad, and user experience—critical for power prototypes.

| Tipo de tratamiento | Objetivo | Power-Specific Applications | Método |

| Pulverización | – Anti-fingerprint coating.- Aislamiento eléctrico (for plastic shells). | – Matte black spray for charger shells (oculta rayones).- Insulating paint for PCBA enclosures (prevents electric shock). | Apply 2–3 thin coats (drying time: 30 minutes per coat); cure at 60°C for 1 hora. |

| Enchapado | – Resistencia a la corrosión (para piezas metálicas).- Conductividad (for grounding components). | – Anodizing aluminum alloy heat sinks (prevents rust and improves heat transfer).- Nickel plating on copper connectors (reduces oxidation). | Use electrolytic plating; control thickness (5–10μm for corrosion resistance). |

| Texture Treatment | – Anti-slip grip.- Brand identification. | – Laser-engraved patterns on charger sides (improves handling).- Silk-screened logos/parameters (input: 100–240V, producción: 5V/2A). | Grabado láser (profundidad: 0.1–0,2 mm) for textures; silk screening with high-adhesion ink (cure at 80°C). |

2.4 Paso 4: Asamblea & Pruebas funcionales (Validate Reliability)

Power prototypes require rigorous testing to ensure safety and performance.

2.4.1 Assembly Process

- Component Preparation: Gather PCBA boards, transformadores, disipadores de calor, cables, and screws (M2–M3 for small power supplies).

- Secure Internal Parts:

- Mount the PCBA to the enclosure using screws or snap fits (ensure no contact with metal parts to avoid short circuits).

- Attach heat sinks with thermal paste (espesor: 0.1milímetros) to high-temperature components (p.ej., voltage regulators).

- Interface Installation: Insert USB-C/DC ports into the shell; solder cables to the PCBA (ensure solid connections to prevent voltage drops).

2.4.2 Critical Tests for Power Prototypes

| Test Type | Método | Acceptance Standard |

| Electrical Performance | Use a multimeter to measure voltage/current output; simulate overload (120% of rated current) and short circuits. | – Voltage output: ±5% of rated value (p.ej., 5V ±0.25V for a 5V charger).- Overload protection: Shuts down within 1 second and reboots safely. |

| Heat Dissipation | Operate the power supply at full load for 2 horas; use an infrared thermometer to measure component temperatures. | – No component exceeds 85°C (critical for lithium battery protection boards).- Enclosure surface temperature ≤45°C (safe for user touch). |

| Structural Durability | Simulate 1000 cycles of plugging/unplugging cables; drop the prototype from 1m onto a hard surface. | – No loose components or cable detachment after testing.- Shell remains intact (no cracks that expose internal circuits). |

3. What Are the Best Practices for Power Prototype Machining?

3.1 Material Selection for Power-Specific Needs

Choose materials based on heat resistance, aislamiento, and structural requirements:

| Material | Propiedades clave | Ideal Power Prototype Components |

| Aleación de aluminio (6061) | Ligero, alta conductividad térmica (167 W/m·K), resistente a la corrosión. | Disipadores de calor, metal enclosures for high-power modules. |

| Plástico ABS | Buena resistencia al impacto, resistencia al calor (hasta 90°C), fácil de mecanizar. | Consumer charger shells, PCBA mounting brackets. |

| POM (Polioximetileno) | Resistente al desgaste, self-lubricating, baja fricción. | Movable parts (folding charger hinges, sliding cable covers). |

| Silicona | Suave, non-slip, resistencia a la temperatura (-50°C to 200°C). | Sealing rings (waterproof power modules), grip covers. |

| Resina (SLA) | Alta precisión, superficie lisa, aislamiento eléctrico. | Appearance prototypes (clear enclosures for LED indicator lights). |

3.2 Precision Control for Safety & Actuación

- Heat Dissipation Holes: Ensure hole diameter is ≥1mm (prevents clogging) and spacing is 5–10mm (maximizes airflow). Use CNC machining for uniform hole placement (avoids 3D printing’s layer-line blockages).

- Screw Holes: Align holes with PCBA mounting points (tolerancia: ±0,1 mm) to prevent component stress. Use CNC drilling for consistent depth (avoids over-drilling that damages internal circuits).

- Interface Cutouts: For USB-C/DC ports, machine cutouts with a 0.1mm clearance around the connector (ensures easy insertion without interference).

3.3 Troubleshooting Common Machining Issues

| Issue | Root Cause | Solución |

| 3D-Printed Shell Warps During Cooling | PLA material shrinks (1.5–2%) after printing; uneven cooling. | – Use a heated bed (60°C for PLA) during printing.- Enclose the printer to maintain consistent temperature.- Design the shell with reinforcement ribs (1–2mm thick) to reduce warping. |

| CNC-Machined Aluminum Has Burrs on Heat Sink Fins | Cutting tool is dull; feed rate too high. | – Replace the tool with a sharpened carbide end mill.- Reduce feed rate by 20% (p.ej., from 1000mm/min to 800mm/min).- Use a deburring wheel to smooth fin edges after machining. |

| Silicone-Duplicated Parts Have Air Bubbles | Silicone mold has no vent holes; resin injected too quickly. | – Add 1–2mm diameter vent holes to the mold’s highest points.- Inject resin slowly (1–2ml/s) to let air escape.- Tap the mold gently during injection to release trapped bubbles. |

La perspectiva de la tecnología Yigu

En Yigu Tecnología, we see power prototype machining as a “safety-first engineering process”—it’s not just about making a physical model, but validating the reliability of a product that handles electricity. Too many clients overlook power-specific needs (p.ej., heat dissipation, aislamiento) and use general machining methods, leading to prototypes that fail functional tests. Our approach: We prioritize material-process matching—e.g., using CNC-machined aluminum for heat sinks (not 3D-printed PLA, which melts at high temperatures) and silicone duplication for soft grips (not CNC plastic, which lacks flexibility). Por ejemplo, we helped a client fix a charger prototype’s overheating issue by machining aluminum heat dissipation fins (replacing a 3D-printed plastic shell), cutting component temperatures by 30%. By focusing on power-specific requirements, we help clients avoid costly reworks and ensure their prototypes align with mass production safety standards.

Preguntas frecuentes

- Can I use 3D printing for a high-power prototype (p.ej., 60W industrial module)?

3D printing is suitable for appearance verification, but not for functional high-power prototypes. High power generates heat (≥80°C) that can melt PLA/ABS. For functional testing, use CNC-machined aluminum alloy (para disipar el calor) or POM (heat-resistant plastic) to ensure the prototype withstands operating temperatures.

- How long does power prototype machining take for a 5V/2A charger?

It depends on the method: 3D printing takes 8–12 hours (including post-processing); CNC machining takes 1–2 days (material setup + corte); silicone duplication takes 3–5 days (fabricación de moldes + replication). Add 1–2 days for assembly and testing.

- What’s the most cost-effective method for 20 units of a custom power enclosure?

Silicone duplication is best. Make a single 3D-printed master prototype (\(20–)50), then produce 20 PU resin copies (\(3–)15 cada) — total cost (\(80–)225) es 50% cheaper than CNC machining 20 separate units (\(150–)400).