If you’re an engineer struggling to turn complex stainless steel designs into physical parts, or a buyer looking for a fast, precise prototyping solution, SLM stainless steel 3D printing prototype technology is your answer. Fusión selectiva por láser (SLM) transforms digital models into high-quality stainless steel prototypes—solving traditional manufacturing pain points like design limits and long lead times. Below, we’ll break down how it works, its benefits, real-world uses, y más.

1. How SLM Stainless Steel 3D Printing Prototype Works: Proceso paso a paso

ElSLM stainless steel 3D printing prototype process is a mix of precision software and advanced machinery. Here’s a clear, actionable breakdown of each step—with key tips to avoid common mistakes:

| Paso | Detailed Actions | Key Tips for Success |

|---|---|---|

| 3D Modeling & STL Export | Use software like SolidWorks or Autodesk Inventor to design your prototype. Export the model as an STL file (the standard for 3D printing). | Ensure your STL file has a “watertight” design (no gaps or overlapping surfaces)—this prevents printing errors. Most software has a “repair” tool for this. |

| rebanar & Configuración de parámetros | Import the STL into slicing tools (p.ej., Magics, Simeji Additive). Set parameters: altura de capa (0.02–0.1mm for stainless steel), laser power (150–300W), yscanning speed (500–1500 mm/s). | For high-strength parts (p.ej., componentes aeroespaciales), use a smaller layer height (0.02–0.05mm) and higher laser power—this improves density. |

| Metal Powder Pretreatment | Screen stainless steel powder to remove clumps (use a 50–100-mesh sieve) and dry it at 80–120°C for 2–4 hours. | Moisture in powder causes pores in the prototype. Always check powder moisture levels with a moisture analyzer before use. |

| SLM Printing | The machine sprays a thin layer of powder on the build platform. A high-energy laser melts the powder in the shape of your design. The platform lowers, and the process repeats until the prototype is done. | Monitor the first 2–3 layers closely—if they don’t stick to the platform, adjust the laser power or platform temperature. |

| Post-Treatment | Remove unmelted powder (use a brush or air blower), cut off support structures, and polish the surface. Heat treat the prototype at 800–1000°C to reduce internal stress. | For parts needing a smooth finish (p.ej., medical tools), use sandblasting (Ra 1.6–3.2 μm) or CNC machining (Ra 0.8–1.6 μm) after heat treatment. |

| Inspección de calidad | Test dimensional accuracy (use a coordinate measuring machine, MMC), check for pores (via X-ray), and verify mechanical properties (resistencia a la tracción, hardness). | Para piezas críticas (p.ej., automotive safety components), require a test report with all inspection data from your supplier. |

2. Why Choose SLM Stainless Steel 3D Printing Prototype? Key Benefits with Data

SLM stainless steel 3D printing prototype outperforms traditional methods (like CNC machining or casting) in three critical areas: design freedom, velocidad, y calidad. Here’s how it delivers value—backed by real numbers:

Design Freedom for Complex Parts

Traditional manufacturing struggles with undercuts, estructuras huecas, or intricate geometries. SLM lets you print parts that would be impossible (or too expensive) to make otherwise. Por ejemplo:

- An aerospace company needed a stainless steel prototype for a fuel injector with 0.5mm-wide internal channels. CNC machining would have required 5+ setups and risked breaking the part. SLM printed the prototype in one piece—saving 40% on production time.

Tiempo de comercialización más rápido

SLM cuts prototyping lead times by 50–70% compared to casting. Let’s compare:

| Prototyping Method | Lead Time for a Medium-Size Stainless Steel Prototype | Costo (for 1–5 Parts) |

|---|---|---|

| Impresión 3D SLM | 3–7 días | $500–$2,000 |

| Fundición | 2–4 semanas | $2,500–$5,000 |

| Mecanizado CNC | 1–2 semanas | $800–$3,000 |

Case Example: A automotive supplier usedSLM stainless steel 3D printing prototype to test a new brake caliper design. They went from 3D model to physical part in 5 days—vs. 3 weeks with casting. This let them iterate 3 times in a month and launch the product 2 months early.

Alta calidad, Durable Prototypes

SLM prototypes have mechanical properties close to fully dense stainless steel. For 316L stainless steel (a common choice), SLM delivers:

- Densidad: 99.5–99.9% (vs. 95–98% for casting)

- Resistencia a la tracción: 570–620 MPa (meets ASTM standards for 316L)

- Dureza: 180–220 HV (enough for most industrial uses)

A medical device maker testedSLM stainless steel prototypes for a surgical tool. The prototypes withstood 10,000+ sterilization cycles (autoclaving at 134°C)—the same as mass-produced parts. This let them skip extra testing and move to production faster.

3. Top Applications of SLM Stainless Steel 3D Printing Prototype

SLM stainless steel 3D printing prototype is used across industries to solve unique challenges. Here are three key sectors and how they leverage the technology:

Aeroespacial & Defensa

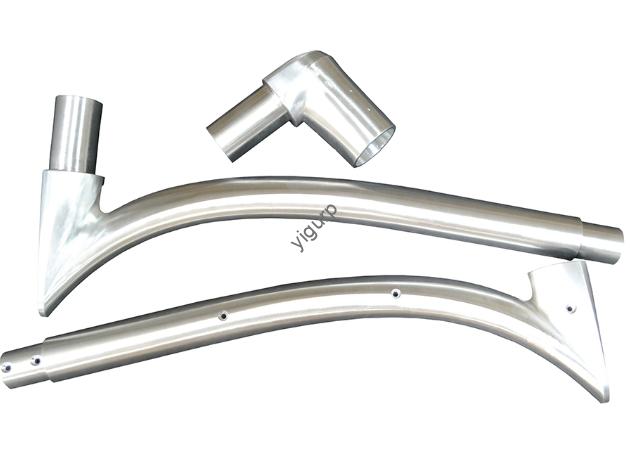

Aerospace parts need to be lightweight, fuerte, and complex. SLM is ideal for prototypes like engine components, paréntesis, or sensor housings. Por ejemplo:

- A defense contractor used SLM stainless steel 3D printing prototype to make a drone engine mount. The prototype was 30% lighter than the CNC-machined version (thanks to hollow internal structures) and met all strength requirements.

Automotor

Car makers use SLM prototypes for parts that need to withstand high temperatures or stress—like exhaust components, turbochargers, or safety parts. A European automaker printedstainless steel prototypes for a new exhaust manifold. They tested the prototype’s heat resistance (up to 800°C) and found a design flaw (a weak spot near the flange) before tooling for mass production—saving $100,000+ in rework costs.

Dispositivos médicos

Acero inoxidable (like 316L) is biocompatible, making it perfect for medical prototypes. A startup developing a dental implant usedSLM stainless steel 3D printing prototype to test different thread designs. The prototypes let them check how well the implant fit in mock jawbones—something 3D simulations couldn’t replicate. They finalized the design in 6 semanas vs.. 3 months with traditional methods.

Yigu Technology’s View on SLM Stainless Steel 3D Printing Prototype

En Yigu Tecnología, we’ve helped 100+ clients leverageSLM stainless steel 3D printing prototype to speed up development. Many come to us after struggling with traditional prototyping—like an industrial equipment maker that couldn’t CNC machine a prototype with internal gears. Our SLM process delivered the part in 4 días, con 99.8% density and perfect gear alignment. We also offer custom parameter tuning: for a client needing high-hardness prototypes, we adjusted laser power and heat treatment to reach 220 HV—meeting their strict specs. For teams wanting to turn bold designs into reliable parts fast, SLM stainless steel 3D printing prototype is the most efficient solution.

FAQ About SLM Stainless Steel 3D Printing Prototype

- What stainless steel materials are available for SLM prototyping?

The most common are 316L (resistente a la corrosión, ideal for medical/aerospace), 304 (versatile, used in automotive/industrial parts), y 17-4 PH (high-strength, good for high-stress components). Some suppliers also offer custom alloys for specific needs. - How much does an SLM stainless steel 3D printing prototype cost?

Costs depend on size, complejidad, and quantity. A small part (5x5x5 cm) costs $300–$800. A medium part (10x10x10 cm) costs $500–$2,000. Para 5+ regiones, you may get a 10–20% volume discount. - Can SLM stainless steel prototypes be used for small-batch production?

Sí! SLM is cost-effective for batches of 1–100 parts. Por ejemplo, a robotics company used SLM to make 50 stainless steel prototypes for a gripper component—avoiding the $10,000+ tooling cost of injection molding.