Servicios de procesamiento de fundición al vacío para prototipos personalizados.

Replicación de silicona (también conocido como fundición al vacío) es una tecnología que utiliza moldes de silicona, Y Yigu es un experto en este campo.. Esta tecnología es una alternativa económica a la producción a pequeña escala de componentes plásticos..

¿Qué es el prototipo de fundición al vacío??

La replicación de silicona es una solución alternativa económica y eficiente para la producción de piezas de plástico a pequeña escala., que puede replicar con precisión las piezas moldeadas finales o los productos terminados. Generalmente, Usamos caucho de silicona para hacer moldes y los combinamos con piezas CNC o SLA como moldes maestros..

Estos moldes son capaces de replicar todas las características estructurales y superficiales de un producto., y el sobremoldeo se puede utilizar para replicar otro producto.. Un juego de moldes de silicona normalmente puede replicar 10-15 conjuntos de productos.

Proceso de producción de replicación de silicona.

fabricación de modelos

Basado en tus dibujos 3D, Utilizaremos mecanizado CNC e impresión 3D. (SLS/SLA) tecnología para producir las piezas principales. Para piezas con formas y estructuras complejas, También consideraremos el uso de tecnología SLA para hacer moldes..

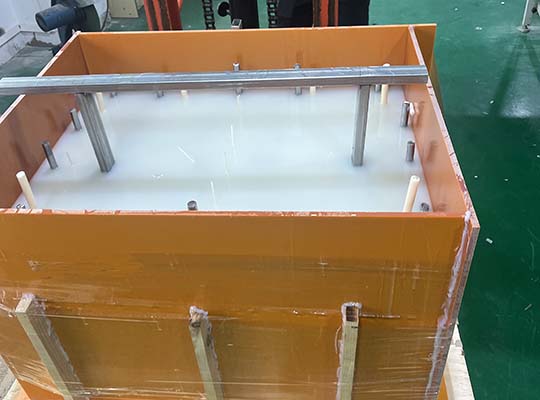

Producción de moldes de silicona.

Inyectaremos silicona alrededor del molde y luego usaremos un proceso de vacío para eliminar todo el aire.. Próximo, colocar el molde en un 40 ℃ horno para curar. El tiempo de curado dependerá de la volumen bajo del molde y generalmente toma 8-16 horas.

Recubrimiento de película al vacío

Vertemos la resina en el molde en la cámara de vacío mediante control informático, y luego volver a meterlo en el horno para curarlo.. En general, el tiempo de curado para componentes pequeños es 1-3 horas, mientras que los componentes grandes requieren 3-6 horas. Después del curado, Retiraremos las piezas fundidas del molde de silicona y nos prepararemos para el siguiente ciclo..

Selección de materiales para fundición al vacío.

Exhibición de prototipos y piezas de fundición al vacío

Los productos mostrados a continuación han sido aprobados por el cliente., y cumplimos estrictamente con el acuerdo de confidencialidad para proteger la confidencialidad y la creatividad del cliente..

Guía de tecnología de duplicación de moldes de silicona

Precisión estándar: La tolerancia estándar es ±0,15 mm/100 mm., con una precisión máxima de ±0,05 mm.

Tamaño máximo de pieza: El equipo de vacío puede adaptarse a las especificaciones del molde de 1.8 metro × 1.2 metro × 1.0 metro.

Espesor mínimo de pared: El espesor mínimo de pared es 0.5 milímetros, y el espesor recomendado está entre 1.5 mm y 2.5 milímetros.

Tiempo de entrega estándar: Arriba a 50 Las piezas se pueden producir dentro 7 a 10 días, dependiendo de las especificaciones de la pieza y la cantidad.

Vida útil de los moldes de silicona.: Cada molde puede producir hasta 20 piezas fundidas, pero si las piezas tienen altos requisitos, como estructuras claras o complejas, entonces un molde solo puede producir 12 o incluso 10 piezas fundidas.

Acabado superficial y otras funciones.: Colorante, texturizar, cuadro, revestimiento, pulido transparente, incrustar, y sobremoldeado.

Ventajas de la fundición al vacío de silicona.

- Un método económico y eficiente para producir lotes pequeños y medianos de piezas de plástico..

- Múltiples materiales, incluyendo poliuretano, epoxy, y silicona suave.

- La opción preferida para funcional. prototipos y productos terminados.

- Bajos costos de molde.

- Tiempos de respuesta rápidos.

silicone vacuum casting application

Silicone molding is suitable for the production of small to medium batches of high-quality, low-cost, and precise plastic parts.

- Industria automotriz: Dashboard components, manijas de las puertas, and interior parts.

- Industrial: Aircraft bodies, structural/functional parts

- Medical industry: Computer electronics shells, chasis y piezas, paréntesis, gabinetes

Why choose our silicone vacuum casting services?

We offer a variety of manufacturing solutions to meet different needs, from sample customization to small-batch production.

Our quality system has obtained ISO 9001:2015 international certification.

Each silicone mold can produce 15 a 18 piezas fundidas, and the production time depends on the scale and standards of the project, usually completed within 7 a 10 días.

We have strong production capabilities, so we can flexibly arrange production cycles to meet your various product production needs.