Servicios de procesamiento de chapa para prototipos personalizados.

Yigu proporciona prototipos de chapa metálica a proveedores de producción de lotes pequeños y medianos, con ISO 9001:2015 fábricas certificadas, ofreciendo una amplia gama de servicios de procesamiento de chapa para satisfacer las necesidades de diversos proyectos, desde simples prototipos de chapa doblada hasta complejos conjuntos mecánicos. Puede obtener piezas estándar en el menor tiempo posible. 3 días.

¿Qué es el prototipo de chapa??

La personalización de prototipos de chapa es un servicio profesional que se centra en la personalización de prototipos de piezas de chapa.. A través de tecnologías avanzadas de procesamiento de chapa, como el corte por láser., estampado, doblando, Cizallamiento etc., Las muestras que cumplen con los requisitos de diseño se pueden fabricar de forma rápida y precisa.. Este servicio se utiliza comúnmente para verificar el diseño del producto., compatibilidad de componentes de prueba, y realizar pruebas funcionales. El proceso de producción de prototipos de chapa es flexible y personalizado., y diferentes materiales, espesores, Y los métodos de tratamiento de superficies se pueden seleccionar según las necesidades del cliente.. Esto ayuda a los clientes a identificar problemas., optimizar diseños, y reducir los costos de producción en las primeras etapas del desarrollo del producto.. Personalizando prototipos de chapa, los clientes pueden obtener rápidamente muestras de alta calidad, proporcionando un fuerte apoyo para el desarrollo de productos.

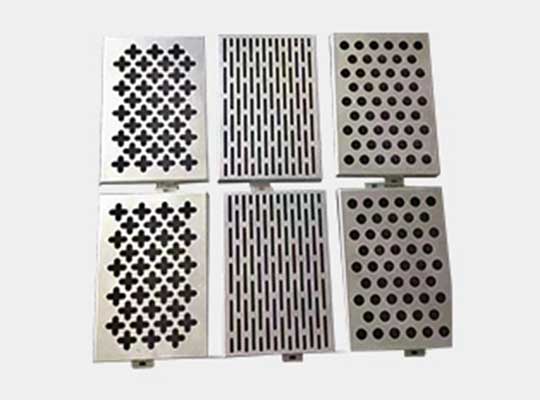

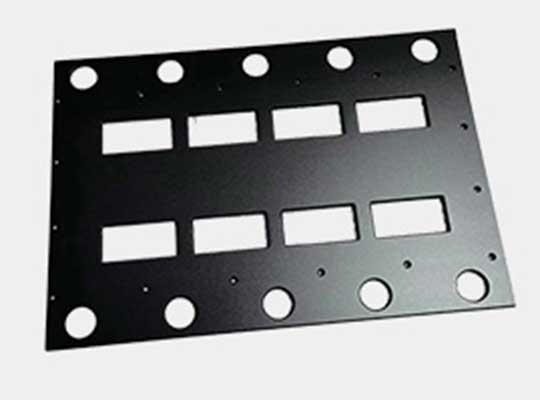

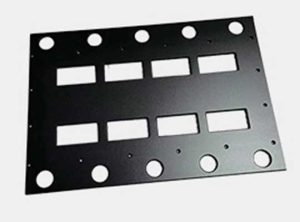

Prototipo de chapa metálica y exhibición de piezas

Los productos mostrados a continuación han sido aprobados por el cliente., y cumplimos estrictamente con el acuerdo de confidencialidad para proteger la confidencialidad y la creatividad del cliente..

Selección de materiales para chapa metálica.

Tratamiento de superficies para el procesamiento de chapa.

Oxidación: anodizado, anodizado duro, anodizado conductivo

Pulverización: chorro de arena, fumigación de aceite, pulverización de polvo

galvanoplastia: cromo, zinc, zinc negro, oro, plata, níquel negro, estaño, níquel, cromo negro, cromo decorativo

Otro: serigrafía, marcado láser, ennegrecimiento, trefilado, pulido electrolítico, pasivación

Complete su prototipo de Chapa Metálica personalizado en 5 pasos

¿Por qué elegirnos??

Ventajas de la fabricación de chapa metálica

Yigu ofrece una opción económica y eficiente para fabricar componentes metálicos.

Podemos moldear fácilmente metales en varias formas., tamaños, y espesores, y también proporcionar

Múltiples opciones de personalización, Incluyendo diferentes métodos de tratamiento de superficies, como anodizado y recubrimiento en polvo..

Aplicación de fabricación de chapa

Industria automotriz: cuerpo, chasis, y otros componentes.

Industria: fuselaje, componentes estructurales, dispositivos fijos.

Industrias electrónica y médica.: carcasas de productos electrónicos informáticos, chasis y piezas, paréntesis, gabinetes.