Si es una empresa que busca llevar un producto al mercado rápidamente en México o atender los mercados de América del Norte desde una base mexicana., creación rápida de prototipos es la clave para acelerar el desarrollo, Recortar costos, y reduciendo riesgos. La pregunta central que la mayoría de los usuarios hacen primero es: ¿Qué hace que la creación rápida de prototipos en México sea una opción viable?, y como empiezo?

En pocas palabras, México ofrece una combinación única de mano de obra calificada, proximidad a los EE.UU.. (reduciendo tiempos y costos de envío), precios competitivos (a menudo 20-30% más bajo que EE. UU.. proveedores), y acceso a la moderna fabricación aditiva y creación de prototipos sustractivos tecnologías. Ya sea que estés en el sector automotriz, aeroespacial, dispositivos médicos, o productos de consumo, El ecosistema de creación rápida de prototipos en México ha crecido significativamente en los últimos cinco años, con importantes centros en ciudades como Monterrey., Ciudad de México, y guadalajara. Esta guía le guiará a través de todo lo que necesita saber., desde las tecnologías disponibles hasta la elección del socio adecuado e historias de éxito del mundo real.

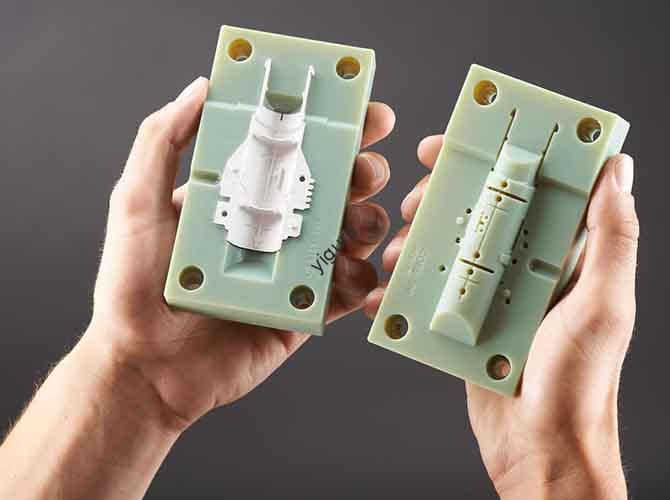

Tecnologías clave de creación rápida de prototipos disponibles en México

Mexico’s prototyping providers now offer a full suite of technologies to match global standards, making it easy to find solutions for nearly any project. Below’s a breakdown of the most common methods, sus casos de uso, and typical lead times in Mexico—critical information for businesses working on tight deadlines.

| Tecnología | Mejor para | Typical Lead Time in Mexico | Gama de materiales |

| MDF (Modelado por deposición fundida) | Partes funcionales, large prototypes, pruebas de bajo costo | 1-3 días | PLA, ABS, PETG, Nylon, Carbon-Fiber Blends |

| SLA (Estereolitografía) | Piezas de alto detalle, superficies lisas (p.ej., dispositivos médicos, bienes de consumo) | 2-4 días | Resinas (rígido, flexible, biocompatible) |

| SLS (Sinterización selectiva por láser) | Durable, piezas resistentes al calor (p.ej., componentes automotrices) | 3-5 días | Nylon, TPU, polipropileno |

| Mecanizado CNC (sustractivo) | Prototipos metálicos, piezas de alta precisión (p.ej., aeroespacial, estampación) | 2-5 días | Aluminio, Acero, Latón, Acrílico |

| Fundición al vacío | Low-volume production runs (10-100 unidades) from a master model | 5-7 días | Resinas de uretano (imitar ABS, ordenador personal, goma) |

Por ejemplo, a startup in Mexico City developing a new smartwatch casing might use SLA for high-detail prototypes to test fit and finish, then switch to MDF with carbon-fiber material for durability testing. Meanwhile, an automotive supplier in Monterrey could rely on Mecanizado CNC to create metal prototypes for engine components—all with lead times that rival U.S. providers but at a lower cost.

¿Por qué elegir México para la creación rápida de prototipos?? Ventajas clave

Businesses—especially those in North America—are turning to Mexico for rapid prototyping for three unbeatable reasons: proximity, costo, y talento. Let’s break down each advantage with concrete data and examples.

Proximidad a los mercados norteamericanos

Mexico’s location next to the U.S. and Canada cuts shipping times and costs dramatically. For a U.S.-based electronics company, sending a prototype from Guadalajara to Austin, Texas, takes just 2-3 days via ground shipping (en comparación con 7-10 days from Asia). This speed is a game-changer for iterative projects, where engineers need to test a prototype, make tweaks, and get a new version quickly.

Estudio de caso: A Detroit-based automotive parts manufacturer switched to a Monterrey-based prototyping shop in 2024. Previously, they’d used a Chinese supplier, with lead times of 14 days for CNC-machined metal prototypes. With Mexico, lead times dropped to 5 días, and shipping costs fell by 60%. This allowed them to reduce their product development cycle by 3 semanas.

Competitividad de costos

Rapid prototyping in Mexico typically costs 20-35% less than in the U.S., sin sacrificar la calidad. This is due to lower labor costs and reduced overhead for providers. Por ejemplo, an SLA prototype that costs \(300 in California might cost \)200-$220 in Mexico City. For small businesses or startups working with tight budgets, this savings can mean the difference between testing one prototype or three.

Key Data: According to the Mexican Association of Advanced Manufacturing (AMFA), the average hourly rate for a skilled rapid prototyping technician in Mexico is \(12-\)18, en comparación con \(25-\)35 en los EE.UU.. This cost difference translates directly to lower project prices for clients.

Talento calificado y ecosistema en crecimiento

Mexico’s government and private sector have invested heavily in STEM education, leading to a growing pool of skilled engineers and technicians trained in additive manufacturing. Major universities like the Monterrey Institute of Technology (ITESM) now offer specialized courses in 3D printing and rapid prototyping, ensuring a steady pipeline of talent.

Además, Mexico’s prototyping hubs (Monterrey, Ciudad de México, Guadalajara) are home to over 50 established providers, many of which are ISO-certified (p.ej., ISO 9001 por la calidad, ISO 13485 para dispositivos médicos). This means businesses can find partners that meet global quality standards without looking outside the country.

Cómo elegir el socio adecuado para la creación rápida de prototipos en México

Not all prototyping shops in Mexico are created equal. Para evitar retrasos, problemas de calidad, o falta de comunicación, follow these four steps to find the right partner for your project.

1. Defina primero los requisitos de su proyecto

Antes de contactar a los proveedores, aclarar:

- El tecnología you need (p.ej., MDF, Mecanizado CNC).

- Especificaciones de materiales (p.ej., resina biocompatible para piezas médicas).

- Cantidad (one prototype or 50 vacuum-cast units).

- Fecha límite (crítico para proyectos urgentes).

- Estándares de calidad (p.ej., Certificaciones ISO, dimensional accuracy tolerances).

Por ejemplo, si está desarrollando un dispositivo médico, you’ll need a partner with ISO 13485 Certificación y experiencia con materiales biocompatibles.. A consumer product company, por el contrario, might prioritize SLA expertise for high-detail parts.

2. Verificar certificaciones y experiencia

Always check a provider’s certifications and past work. Buscar:

- ISO 9001 (gestión de calidad) or industry-specific certifications (ISO 13485 para médico, AS9100 para el sector aeroespacial).

- Case studies or a portfolio of projects similar to yours.

- Client references (pedir 1-2 contacts to confirm reliability).

Ejemplo: A aerospace startup in Baja California recently vetted three prototyping shops. They eliminated one shop because it lacked AS9100 certification, and another because it had no experience with heat-resistant SLS materials. The third shop—with both the certification and a portfolio of aerospace parts—delivered prototypes that met all their requirements.

3. Evaluar la comunicación y la gestión de proyectos.

Clear communication is critical, especially if you’re based outside Mexico. Choose a partner that:

- Has English-speaking staff (to avoid translation errors).

- Uses project management tools (p.ej., Trello, Asana) to share updates.

- Provides regular progress reports (p.ej., photos of the prototype mid-production).

A common pain point for U.S. clients is miscommunication about design files. A good partner will review your CAD files upfront, flag potential issues (p.ej., unprintable features), and suggest fixes—saving you time and money.

4. Compare precios y plazos de entrega (Pero no sacrifiques la calidad)

Obtener cotizaciones de 2-3 providers to compare pricing, but avoid choosing the cheapest option outright. A slightly higher price might mean better quality, tiempos de entrega más rápidos, or more responsive customer service. Ask for a detailed breakdown of costs (p.ej., material, mano de obra, envío) to ensure there are no hidden fees.

Historias de éxito del mundo real: Rapid Prototyping in Mexico

To illustrate how businesses are leveraging Mexico’s prototyping ecosystem, here are two detailed case studies across different industries.

Estudio de caso 1: Medical Device Startup Reduces Time-to-Market

A Mexican startup in Guadalajara was developing a portable blood glucose monitor for rural clinics. They needed to test 5 iterations of the device’s casing and internal components before finalizing the design.

- Desafío: The startup had a tight 3-month timeline to get the prototype approved by Mexico’s regulatory body (COFEPRIS) and needed high-detail parts that met medical standards.

- Solución: They partnered with a local prototyping shop specializing in SLA and biocompatible resins. The shop reviewed their CAD files, suggested minor design tweaks (p.ej., rounding sharp edges for patient comfort), and delivered each prototype in 3 días.

- Resultado: The startup tested all 5 iteraciones en 6 semanas (half the time they’d planned), got COFEPRIS approval, and launched the product 2 meses antes de lo previsto. The cost of prototyping was 25% lower than quotes from U.S. proveedores.

Estudio de caso 2: A NOSOTROS. Automotive Supplier Cuts Costs

A U.S.-based supplier of automotive sensors needed to prototype a new temperature sensor for electric vehicles (vehículos eléctricos). They previously used a U.S. CNC machining shop but faced high costs and long lead times.

- Desafío: The sensor’s metal housing required tight tolerances (±0,001 pulgadas) to fit EV engines, and the supplier needed 10 prototypes for testing.

- Solución: They switched to a Monterrey-based shop with ISO 9001 y la IATF 16949 (calidad automotriz) certificaciones. The shop used CNC machining with aluminum alloy and delivered the prototypes in 4 días.

- Resultado: The supplier saved 30% on prototyping costs and reduced lead times by 50%. The prototypes met all tolerance requirements, and the sensor was approved for production 1 month earlier than expected.

Yigu Technology’s Perspective on Rapid Prototyping in Mexico

En Yigu Tecnología, we see Mexico as a rapidly growing hub for rapid prototyping that offers unique value to global businesses—especially those targeting North American markets. The combination of proximity, skilled talent, and cost competitiveness makes Mexico an attractive alternative to both U.S. and Asian providers.

What stands out most is Mexico’s focus on quality and innovation. Many local prototyping shops have invested in state-of-the-art equipment (p.ej., industrial-grade 3D printers, high-precision CNC machines) and obtained global certifications, ensuring they can meet the needs of industries like aerospace and medical devices. For businesses looking to streamline their supply chains, Mexico also offers the advantage of easier collaboration—shorter shipping times mean faster iterations, which is crucial in today’s fast-paced product development landscape.

We recommend businesses explore Mexico’s prototyping ecosystem, especially if they’re working on projects that require frequent design tweaks or tight deadlines. By partnering with a reputable local shop, companies can reduce costs without compromising on quality or speed.

Preguntas frecuentes: Common Questions About Rapid Prototyping in Mexico

1. What’s the typical lead time for a rapid prototype in Mexico?

Lead times vary by technology but generally range from 1-7 días. FDM and SLA prototypes are fastest (1-3 días), while CNC machining and vacuum casting take 2-7 días. Para proyectos urgentes, most shops offer expedited services (p.ej., 24-hour turnaround for small FDM parts) por una tarifa adicional.

2. Do Mexican prototyping shops work with international clients?

Yes—many shops have experience working with U.S., canadiense, and European clients. They typically accept CAD files in common formats (p.ej., STL, PASO), offer English-speaking support, and handle international shipping (via carriers like FedEx or DHL).

3. Are there any quality risks with rapid prototyping in Mexico?

Not if you choose a certified provider. Look for shops with ISO 9001, ISO 13485 (médico), o IATF 16949 (automotor) certificaciones. Most reputable shops also offer quality checks (p.ej., pruebas dimensionales, inspecciones visuales) and will share photos or reports before shipping.

4. Can Mexican shops handle large or complex prototypes?

Sí. Many shops have industrial-grade equipment, such as large-format FDM printers (capable of parts up to 1m in size) and 5-axis CNC machines (for complex metal parts). For extremely large prototypes, some shops offer assembly services to piece together multiple components.

5. How do I send my design files to a Mexican prototyping shop?

Most shops accept files via email, cloud storage (p.ej., Google Drive, Dropbox), or project management tools. It’s best to send CAD files in STL, PASO, or IGES format, as these are widely compatible. If you’re unsure about your design, ask the shop for a design review—many offer this service for free or at a low cost.