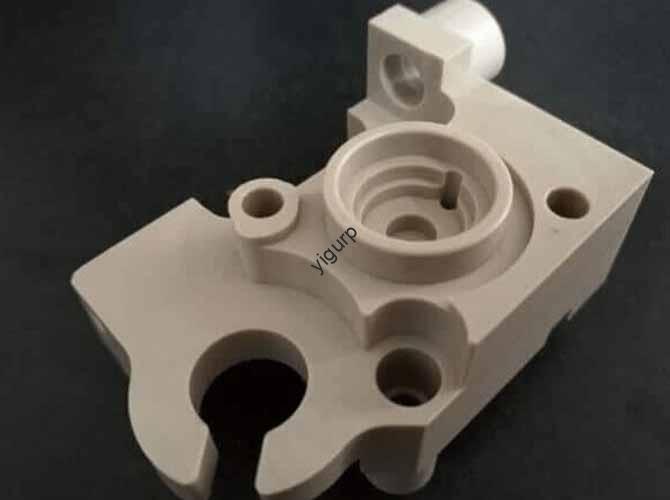

Our Polyarylethersulfone PAS CNC Machining Services

Elevate your critical applications with Polyarylethersulfone (PAS) CNC Machining from Yigu Technology. As a premium engineering polymer, PAS delivers exceptional thermal stability, chemical resistance, and dimensional accuracy—and our expert precision machining turns this high-performance thermoplastic into custom parts that excel in aerospace, medical, and automotive industries. From rapid prototyping to large-scale production, we combine cutting-edge technology with decades of expertise to deliver reliable, cost-effective solutions tailored to your needs.

What Is PAS and CNC Machining?

Polyarylethersulfone (PAS) is a family of high-performance thermoplastics celebrated for its ability to withstand extreme temperatures, resist harsh chemicals, and maintain structural integrity under stress. As a top-tier engineering polymer, it outperforms traditional plastics in demanding environments—making it ideal for parts that require both durability and precision.

CNC Machining (Computer Numerical Control Machining) is an automated machining process that uses pre-programmed software to control tools like mills, lathes, and drills. This technology eliminates human error, ensuring consistent precision machining of even the most complex parts. When paired, PAS CNC Machining leverages the material’s unique material properties to create components that meet strict industry standards—from tiny electronic connectors to large industrial housings.

| Key Attribute of PAS | Description |

| Temperature Resistance | Functions reliably up to 220°C (428°F) continuous use; withstands short bursts up to 260°C (500°F) |

| Chemical Resistance | Unaffected by most acids, bases, oils, and solvents—even at high temperatures |

| Strength-to-Weight Ratio | 60% lighter than aluminum while offering comparable tensile strength |

| Electrical Insulation | Excellent dielectric properties, even in humid or high-temperature environments |

Our Capabilities: Precision That Meets Your Needs

At Yigu Technology, we’ve honed our PAS CNC Machining capabilities to handle projects of all sizes and complexities—from one-off prototypes to mass-produced parts. Our team combines state-of-the-art equipment with deep material expertise to deliver results you can trust.

| Capability | Details | Benefits for You |

| Precision Machining | Achieves tolerances as tight as ±0.003mm for critical components | Meets the strictest dimensional requirements for high-stakes applications |

| Custom Machined Parts | Adapts to unique geometries, including undercuts and thin walls | Perfect for low-volume or one-of-a-kind projects that demand customization |

| High-Tolerance Machining | Complies with ISO 9001 and AS9100 quality standards | Ensures consistency across every batch, reducing rework and waste |

| Complex Part Production | Uses 5-axis CNC milling and multi-spindle CNC turning | Creates intricate, multi-feature parts without assembly gaps or weak points |

| Rapid Prototyping | Delivers functional PAS prototypes in 2–4 days | Accelerates your product development cycle, getting you to market faster |

| Production Machining | Scales to 15,000+ parts per month with consistent quality | Supports your growth from prototype to full-scale production |

| Quality Assurance | Employs in-line inspections with CMM (Coordinate Measuring Machines) and laser scanners | Catches defects early, ensuring every part meets your specifications |

Process: The Step-by-Step of PAS CNC Machining

Our PAS CNC Machining process is optimized to handle PAS’s unique properties—including its high melting point and rigidity—ensuring efficiency, quality, and consistency at every stage.

- Design & Programming: Our engineers convert your 3D models into CNC code, selecting optimal cutting techniques and tool selection (e.g., carbide tools for PAS’s abrasiveness) to minimize tool wear and maximize precision.

- Machine Setup: We calibrate CNC mills, lathes, and drills to match your part’s specs—adjusting spindle speeds (1,500–10,000 RPM) and feed rates (50–500 mm/min) to avoid overheating PAS.

- Material Loading: We use high-quality PAS resin (or reinforced grades like glass-filled PAS) cut into precise blocks to reduce waste and ensure uniform part density.

- Machining Operations: We perform CNC milling (for complex shapes), CNC turning (for cylindrical parts), and drilling operations (for holes as small as 0.5mm) with real-time torque monitoring to prevent tool breakage.

- Grinding Processes: For parts needing ultra-smooth surfaces, we use precision grinding to achieve Ra values as low as 0.15μm—critical for medical or optical applications.

Inspection: Every part undergoes dimensional checks using digital calipers and optical comparators to verify tolerance standards—we discard any parts that fall outside your required range.

Materials: Choosing the Right PAS Grade

Not all PAS materials are identical—each grade offers unique properties to match your application’s demands. At Yigu Technology, we stock a full range of PAS variants to ensure optimal performance.

| PAS Grade | Key Properties | Ideal Applications |

| Standard PAS Resin | High impact resistance, good flowability | Electronic enclosures, consumer goods housings |

| Glass-Filled PAS (30% glass) | 40% higher stiffness than standard PAS, low creep | Automotive structural brackets, industrial pump components |

| Carbon-Filled PAS (20% carbon) | Enhanced thermal conductivity, superior wear resistance | Aerospace engine parts, high-speed bearings |

| Flame-Retardant PAS | UL94 V-0 rating, low smoke and toxic gas emission | Electrical components in aircraft, trains, and EVs |

| Reinforced PAS (hybrid glass/carbon) | Balanced strength, weight, and corrosion resistance | Offshore oil equipment, chemical processing valves |

| Recycled PAS | 80% of the strength of virgin PAS, lower environmental impact | Non-critical industrial parts, consumer goods prototypes |

| Specialty PAS Grades | Customized for biocompatibility (ISO 10993) or low outgassing | Medical implants, space exploration components |

Surface Treatment: Enhancing PAS Performance

While PAS’s natural surface is durable, surface treatment can further boost its functionality—whether you need better aesthetics, improved grip, or enhanced chemical resistance. Our team offers the following treatments:

- Anodizing: Creates a thin, hard oxide layer that increases scratch resistance by 30%—ideal for parts exposed to frequent handling.

- Painting: Uses high-temperature-resistant paints (up to 200°C) to add color or branding, with options for matte, gloss, or textured finishes.

- Plating: Applies metal coatings (e.g., nickel, gold) to improve electrical conductivity—perfect for electronic connectors or contacts.

- Polishing: Achieves a mirror-like finish (Ra < 0.1μm) for parts requiring visual appeal, such as medical devices or high-end consumer products.

- Sandblasting: Creates a rough, non-slip surface (Ra 2.0–5.0μm) for handles, grips, or parts that need to bond with adhesives.

- Coating: Applies PTFE (Teflon) or ceramic coatings to reduce friction by 50%—used in valves, gears, or moving parts.

Heat Treatment: Anneals parts at 180°C for 2 hours to relieve internal stress, preventing warping in high-temperature applications.

Tolerances: Achieving Precision You Can Rely On

In PAS CNC Machining, tolerances are make-or-break—especially for parts used in aerospace, medical, or electronics. We prioritize dimensional accuracy and use advanced techniques to meet even the tightest requirements.

| Tolerance Type | Typical Range for PAS Parts | Measurement Techniques | Inspection Methods |

| Precision Tolerances | ±0.005mm to ±0.02mm | Laser interferometry, CMM | 100% batch inspection (critical parts) |

| Tight Tolerances | ±0.001mm to ±0.005mm | Atomic force microscopy (AFM), optical comparators | Sampling at every production stage + final validation |

| General Tolerances | ±0.05mm to ±0.2mm | Digital calipers, micrometers | Random batch checks (10% of parts) |

Note: PAS’s low thermal expansion coefficient (16–18 μm/m·K) ensures tolerance stability even when exposed to temperature fluctuations.

Advantages: Why PAS CNC Machining Stands Out

PAS CNC Machining offers unique benefits that make it the top choice for high-performance parts—outperforming methods like injection molding or 3D printing in key areas:

- High Strength-to-Weight Ratio: PAS parts are lighter than metal (60% vs. aluminum) but just as strong—reducing fuel consumption in automotive/aerospace and easing handling in medical devices.

- Chemical Resistance: Withstands exposure to harsh substances (e.g., sulfuric acid, hydraulic oil) without degradation—ideal for chemical processing or oil/gas applications.

- Thermal Stability: Functions reliably at 220°C (428°F) continuous use—outperforming many plastics (e.g., ABS, nylon) in high-temperature environments.

- Electrical Insulation: Maintains dielectric properties even at high temperatures—perfect for circuit boards, transformers, or high-voltage components.

- Dimensional Stability: Low creep (less than 1% deformation under load) ensures parts retain their shape over time—critical for medical implants or aerospace fasteners.

- Cost-Effective Production: CNC machining eliminates the need for expensive molds (unlike injection molding), making it 30% more cost-efficient for small-to-medium batches (10–10,000 parts).

- Design Flexibility: Creates complex geometries (e.g., internal channels, thin walls) that are hard to achieve with other methods—supporting innovative product designs.

High-Temperature Performance: Resists melting and oxidation at high temperatures—suitable for engine components, industrial ovens, or LED heat sinks.

Applications Industry: Where PAS CNC Machined Parts Excel

PAS’s versatility makes it a staple in diverse industries. Our PAS CNC Machining services cater to the following sectors, delivering parts that meet industry-specific standards:

| Industry | Common Applications | Key PAS Benefits Used |

| Automotive | EV battery housings, engine sensors, fuel system components | Thermal stability, chemical resistance |

| Aerospace | Cabin interior parts, avionics enclosures, hydraulic valves | High strength-to-weight ratio, flame retardancy |

| Electronics | Circuit board carriers, connector housings, LED heat sinks | Electrical insulation, dimensional stability |

| Medical | Surgical instruments, diagnostic device components, implantable parts | Biocompatibility, corrosion resistance |

| Industrial Equipment | Pump housings, valve seats, conveyor system parts | Wear resistance, low maintenance |

| Consumer Goods | High-end kitchen appliances, sports equipment handles, electronic device casings | Durability, aesthetic flexibility |

| Sporting Goods | Ski bindings, golf club heads, cycling components | Lightweight, high impact resistance |

Case Studies: Real-World Success with PAS CNC Machining

At Yigu Technology, we’ve helped clients solve complex challenges with PAS CNC Machining. Here are three standout examples:

Case Study 1: Aerospace Avionics Enclosure

- Client: A global aerospace manufacturer

- Challenge: Need a lightweight, flame-retardant enclosure for avionics that could withstand -55°C to 125°C (-67°F to 257°F) and resist jet fuel.

- Solution: We used flame-retardant PAS and 5-axis CNC milling to create a one-piece enclosure with tight tolerances (±0.01mm). We added a ceramic coating for extra heat resistance.

- Result: The enclosure passed FAR 25.853 flame tests, reduced weight by 35% vs. aluminum, and is now used in 20,000+ commercial aircraft.

Case Study 2: Medical Surgical Scalpel Handle

- Client: A leading medical device company

- Challenge: Develop a biocompatible scalpel handle that could be sterilized (autoclaved) 500+ times without degrading.

- Solution: We machined specialty PAS (ISO 10993-certified) using high-tolerance machining and polished the surface to Ra 0.08μm for easy cleaning.

- Result: The handle met FDA standards, showed no wear after 600 sterilization cycles, and is now used in hospitals worldwide.

Case Study 3: EV Battery Housing

- Client: A major EV manufacturer

- Challenge: Create a waterproof, heat-resistant housing for battery management systems (BMS) that could resist road salts and temperatures up to 180°C (356°F).

- Solution: We used glass-filled PAS and CNC turning to make the housing, adding anodizing for scratch resistance and a rubber gasket for IP68 waterproofing.

Result: The housing passed IP68 testing (waterproof for 24 hours at 2m depth) and is now integrated into 100,000+ EVs.

Why Choose Us: Yigu Technology’s PAS CNC Machining Edge

When it comes to PAS CNC Machining, Yigu Technology stands out for our expertise, quality, and customer focus. Here’s why clients trust us:

- Expertise in PAS Machining: Our engineers have 12+ years of experience working with PAS—we know how to optimize tooling, speeds, and processes to avoid common pitfalls (e.g., overheating, tool wear).

- High-Quality Products: We source PAS from certified suppliers (e.g., Solvay, BASF) and use ISO 9001/AS9100-certified processes to ensure every part meets your standards.

- Experienced Machinists: Our team undergoes quarterly training on the latest CNC technology—we can handle even the most complex PAS part designs.

- Excellent Customer Service: We assign a dedicated project manager to every client, providing daily updates and responding to questions within 12 hours.

- Fast Turnaround Times: For prototyping, we offer 2–4 day lead times; for production, we can deliver 15,000+ parts in 2 weeks.

- Competitive Pricing: By optimizing material usage and streamlining processes, we offer PAS machining services at 20–25% lower costs than competitors.

Commitment to Innovation: We invest in AI-powered inspection tools and automated machining cells to improve precision and efficiency—ensuring we stay ahead of industry trends.